Fractionating column feed method for improving distillate yield

A technology of fractionation tower and distillate oil, which is applied in the field of improving the yield of distillate oil in distillation equipment, and can solve the problems of affecting the quality of tower top and side line products, affecting the yield of distillate oil, reducing the heat transfer coefficient, etc., and achieving the suppression of thermal cracking reaction , reduce mist entrainment, and increase the overall heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 illustrates the effect of the method provided by the invention for vacuum distillation of crude oil.

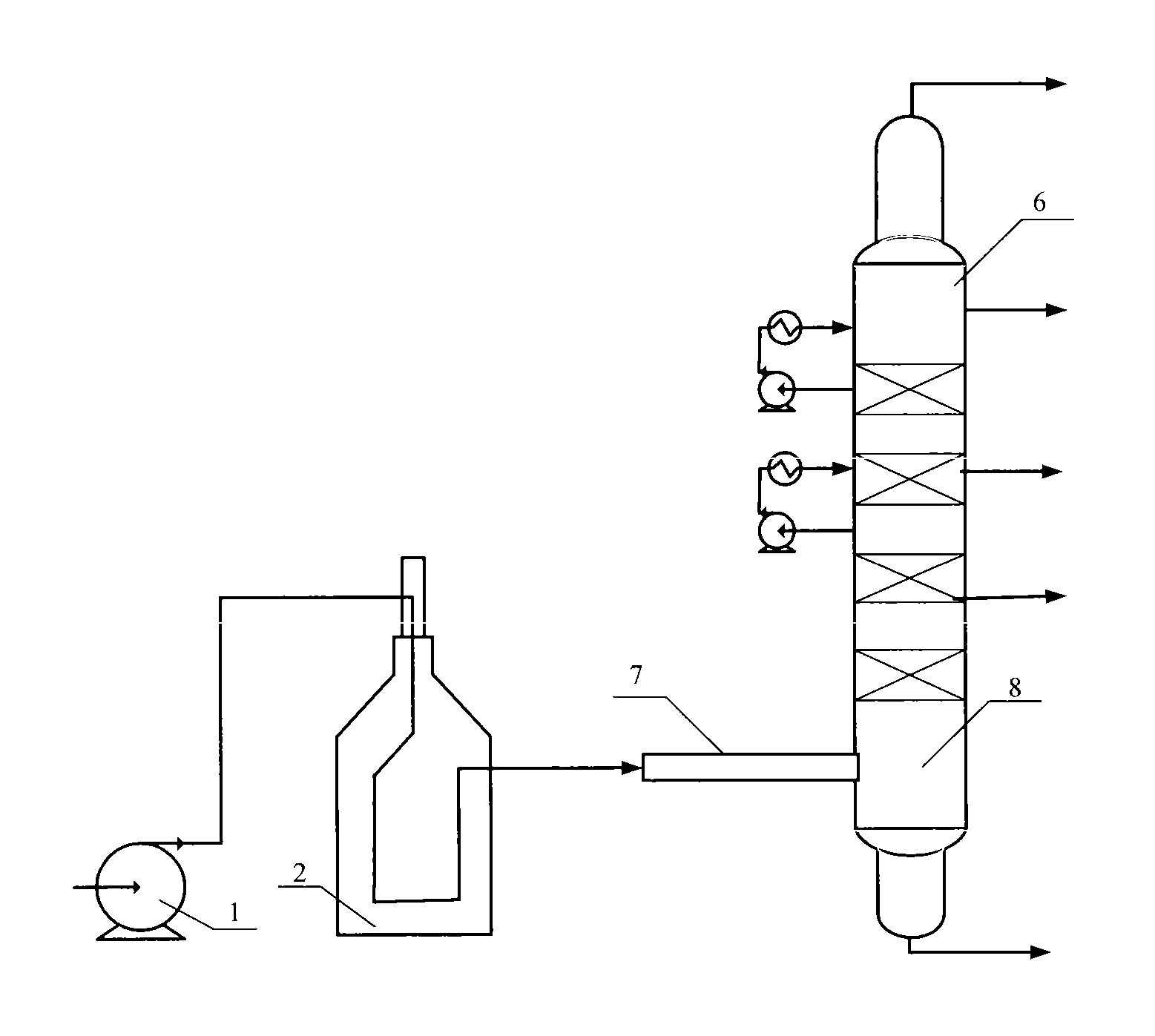

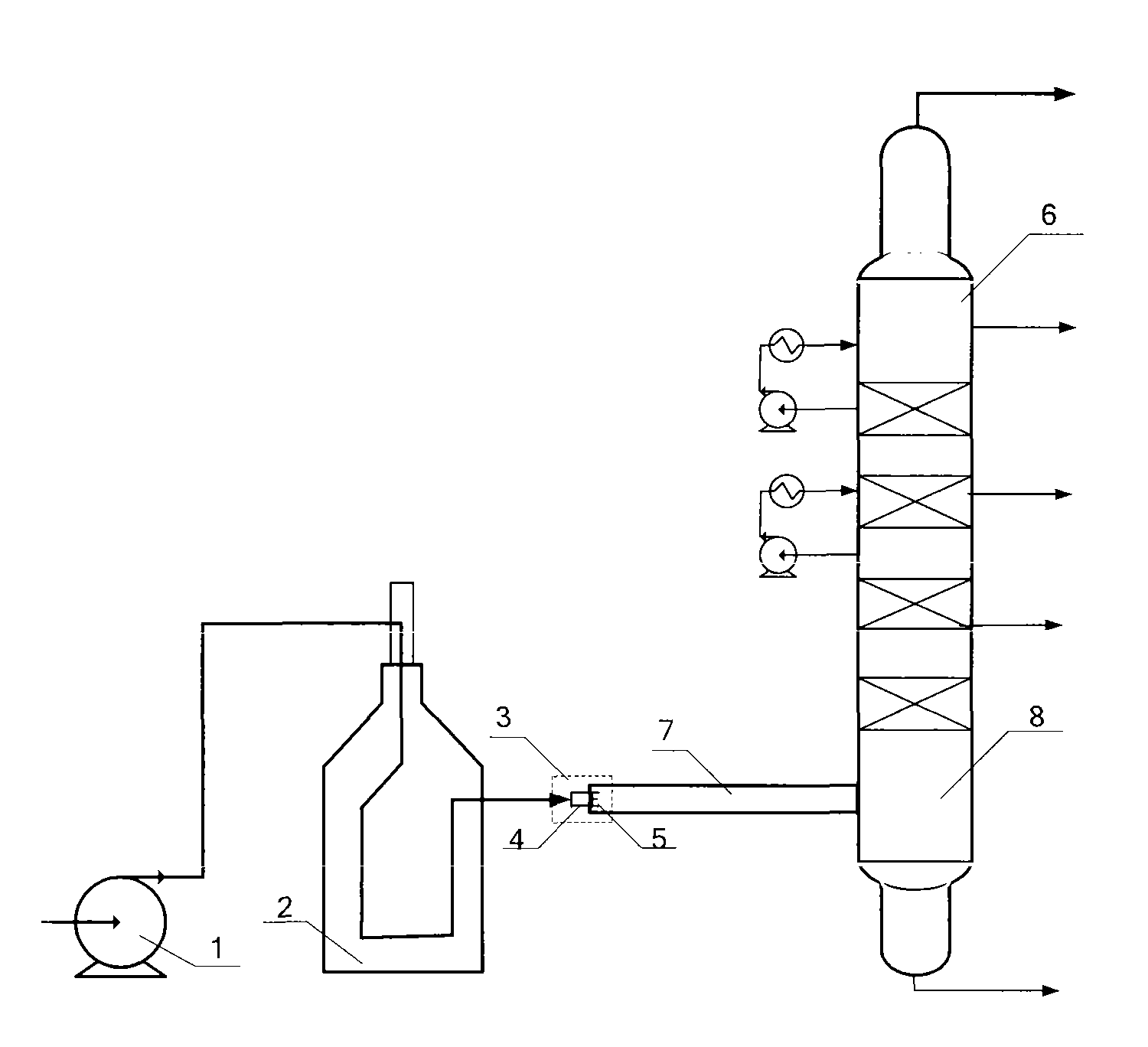

[0043] The atmospheric tower system and the mixed crude oil to be fractionated are the same as those in the comparative example, and the extraction rate of the atmospheric tower is 32wt%. as attached figure 2 As shown, the bottom oil obtained by the fractional distillation of the atmospheric distillation tower is first transported to the heating furnace 2 of the vacuum distillation system through the oil pump 1, and the heated atmospheric bottom oil is sprayed into the oil transfer line 7 through the nozzle 5, and the bottom oil of the atmospheric pressure column is The oil is fully vaporized in the oil transfer line, and then introduced into the vaporization section 8 of the vacuum tower through the oil transfer line. The pressure at the inlet of the oil transfer line is 14.0kPa, and the temperature is 386°C. The nozzle used is a high-efficiency atomizing...

Embodiment 2

[0046] Example 2 illustrates the effect of the method provided by the invention for vacuum distillation of crude oil.

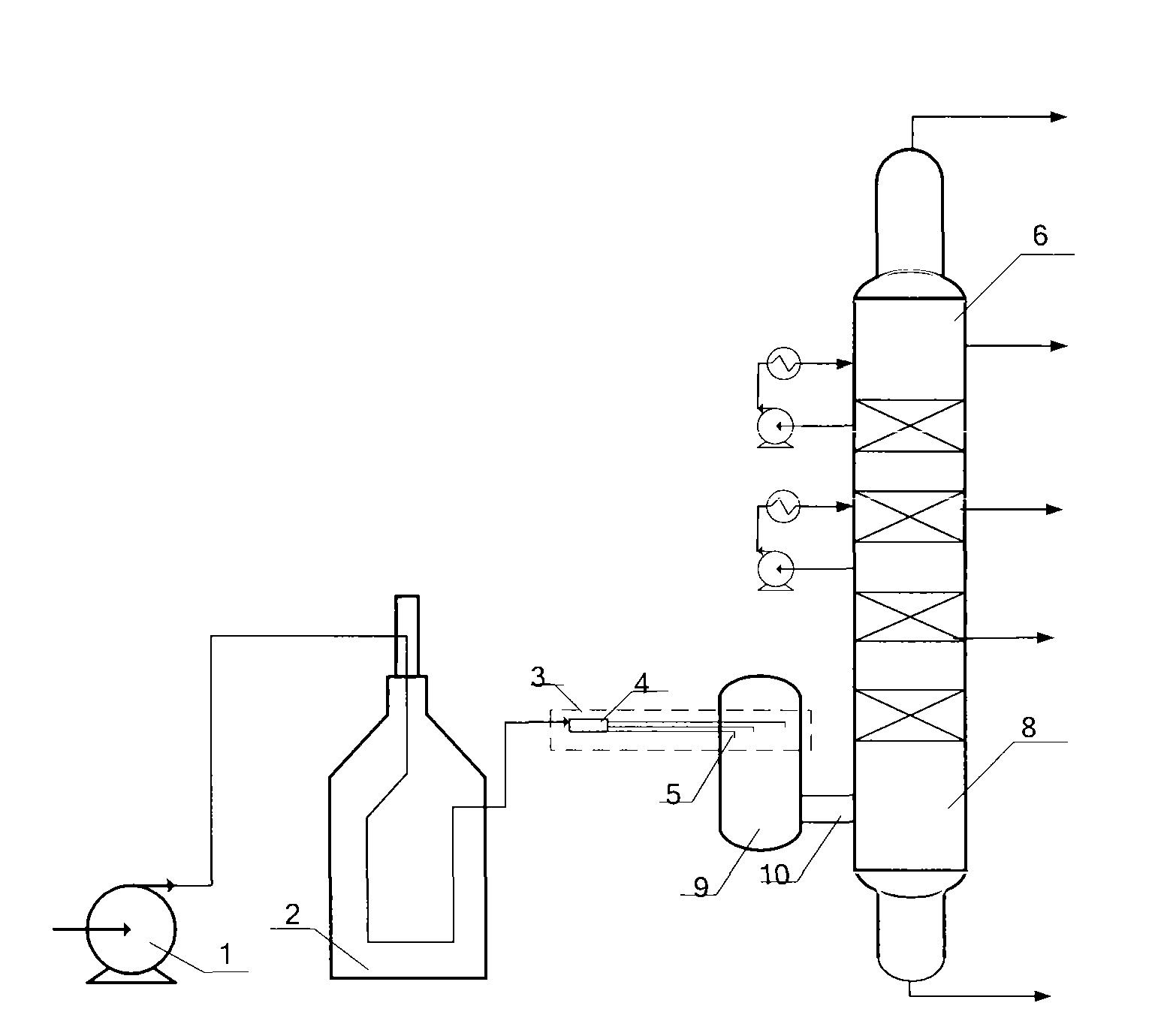

[0047] The atmospheric tower system and the mixed crude oil to be fractionated are the same as those in the comparative example, and the extraction rate of the atmospheric tower is 32wt%. as attached image 3 As shown, the structure of the vacuum tower used is the same as that of the comparative example, and the structure of the heating furnace used is the same as that of Example 1. The difference is that a flash tank 9 is added behind the decompression furnace. The bottom oil of the atmospheric pressure tower is distributed by the flow distribution system 4 and sprayed into the flash tank through the nozzle 5. After being fully vaporized, it is introduced into the vacuum distillation tower In the vaporization section, the pressure of the flash tank is 6.1kPa and the temperature is 382°C. See Table 2 for other main operating conditions and product properties...

Embodiment 3

[0050] Example 3 illustrates the effect of the method provided by the invention for vacuum distillation of crude oil.

[0051] The atmospheric tower system and the mixed crude oil to be fractionated are the same as those in the comparative example, and the extraction rate of the atmospheric tower is 32wt%. The structure of the decompression tower used in embodiment 3 is the same as that of comparative example, the structure of the heating furnace used is the same as that of embodiment 1, and all flash tanks are the same as that of comparative example 2. as attached Figure 4 As shown, the bottom oil of the atmospheric column is distributed by the flow distribution system 3 and sprayed into the flash tank 9 through the nozzle 5. After being fully vaporized, the gas and liquid are respectively introduced into the vacuum distillation tower from different pipelines. The pressure of the steamer is 6.1kPa, and the temperature is 382°C. The main operating conditions and product pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com