Fixed bed fischer-tropsch synthesis method

A technology of Fischer-Tropsch synthesis and Fischer-Tropsch synthetic oil, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry. It can solve the problems that the overall performance of the catalyst cannot be uniformly exerted, so as to reduce the axial temperature difference, increase the yield, and improve the selectivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

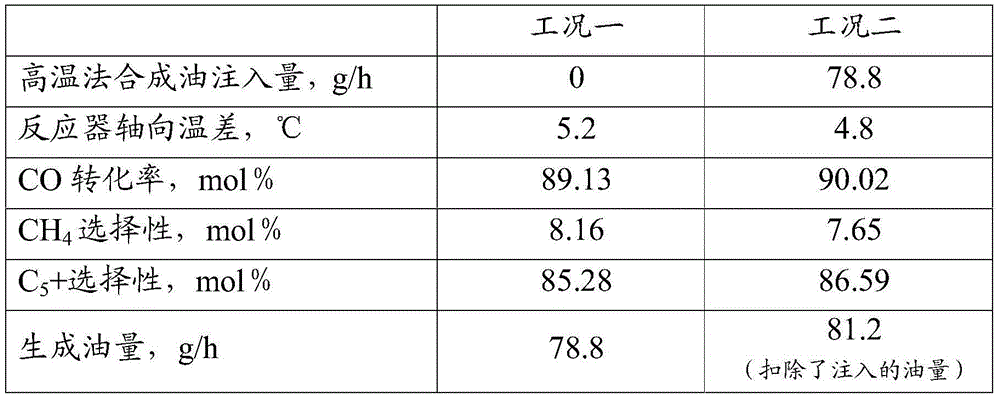

[0034] The Fischer-Tropsch synthesis reaction was carried out on the aforementioned fixed-bed Fischer-Tropsch synthesis test device. Firstly, the working condition test (working condition 1) without injection of high-temperature Fischer-Tropsch synthetic oil was carried out. The operating conditions of the device are: average reaction temperature 215°C, pressure 2.5MPa, reactor inlet H 2 / CO molar ratio is 2.0, synthesis gas volume space velocity is 500h -1 , Cycle ratio 8. After the device operated stably for 100 hours, the axial temperature difference of the reactor and the Fischer-Tropsch synthesis reaction effect were calculated, and the amount of oil produced by the reaction was 78.8g / h.

[0035] Then, inject the low-temperature condensate of the high-temperature Fischer-Tropsch synthesis (working condition 2) into the inlet of the reactor, and the injection amount is twice the amount of synthetic oil produced in the previous stage, that is, 78.8g / h. After the oil was ...

Embodiment 2

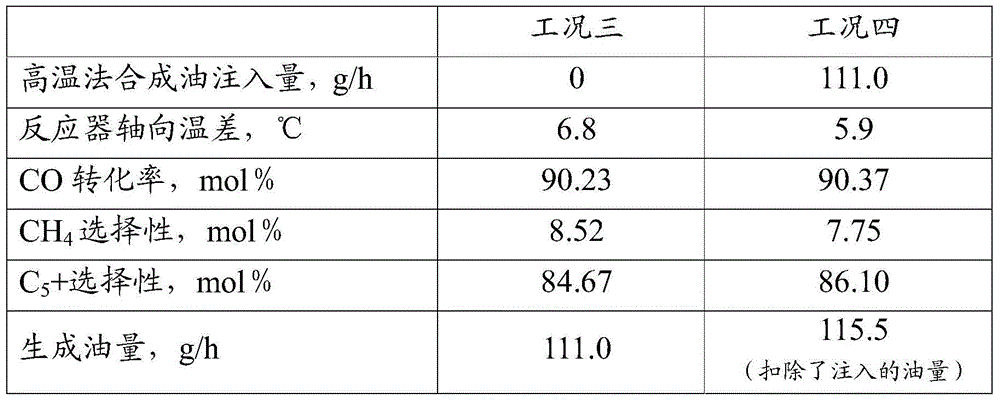

[0043] The Fischer-Tropsch synthesis reaction was carried out on the aforementioned fixed-bed Fischer-Tropsch synthesis test device. First, the working condition test (working condition 3) without injection of high-temperature Fischer-Tropsch synthetic oil was carried out. The operating conditions of the device are: average reaction temperature 218°C, pressure 2.5MPa, reactor inlet H 2 The / CO molar ratio is 2.1, and the volumetric space velocity of the syngas is 700h -1 , Cycle ratio 6. After the device operated stably for 100 hours, the axial temperature difference of the reactor and the Fischer-Tropsch synthesis reaction effect were calculated, and the amount of oil produced by the reaction was 111.0g / h.

[0044] Then, inject the low-temperature condensate of the high-temperature Fischer-Tropsch synthesis (working condition 4) into the reactor inlet, and the injection amount is twice the amount of synthetic oil generated in the previous stage, that is, 222g / h. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com