Crude oil distilling method and device for pressure type feeding

A crude oil distillation and pressure-type technology, which is only applied in the direction of multi-stage series refining process, can solve the problems of unreached equilibrium vaporization rate, reduce the amount of non-condensable gas at the top of the tower, increase the mass transfer area, and reduce the equipment The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Examples illustrate the effect of the pressure feed crude oil distillation method provided by the present invention.

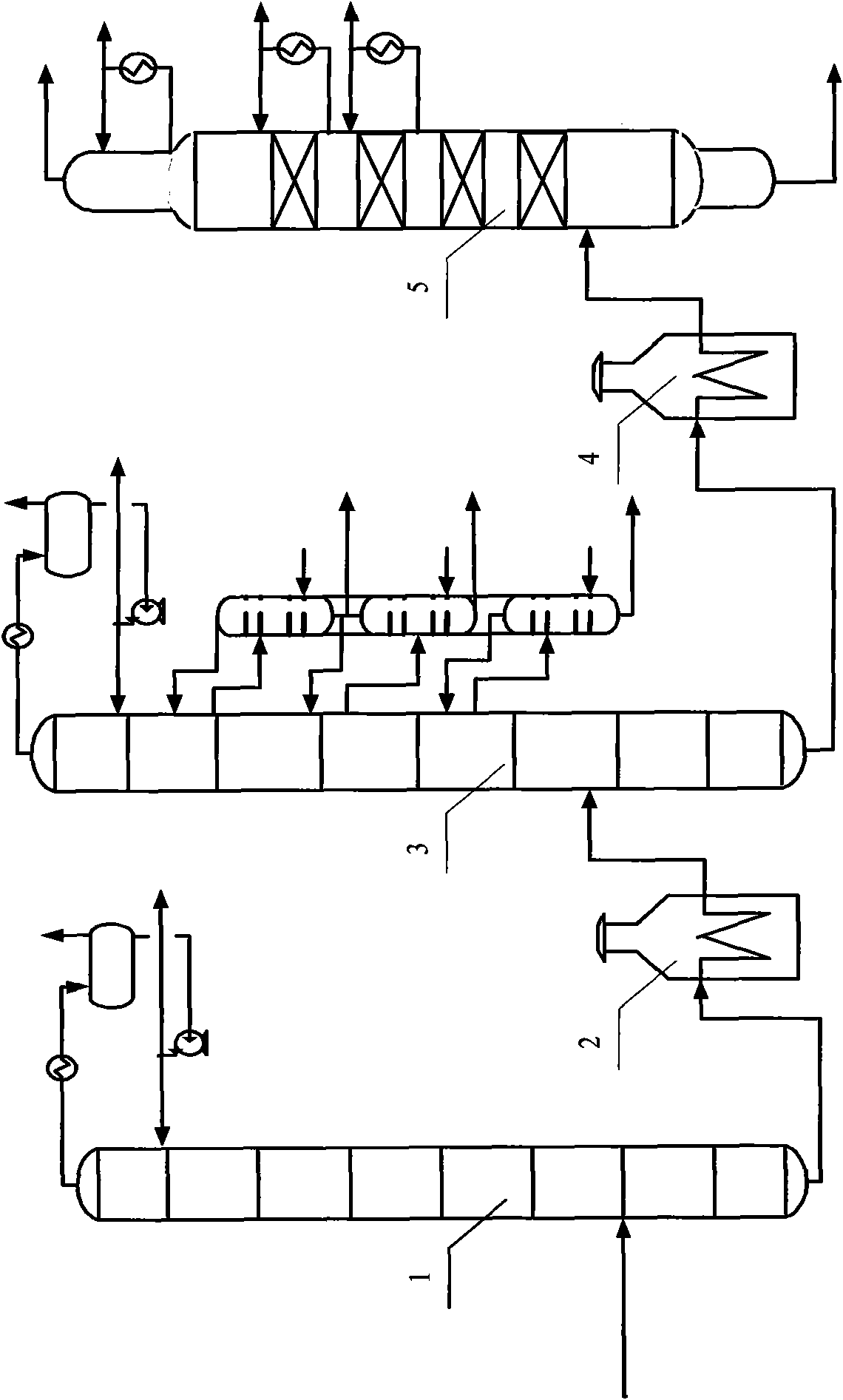

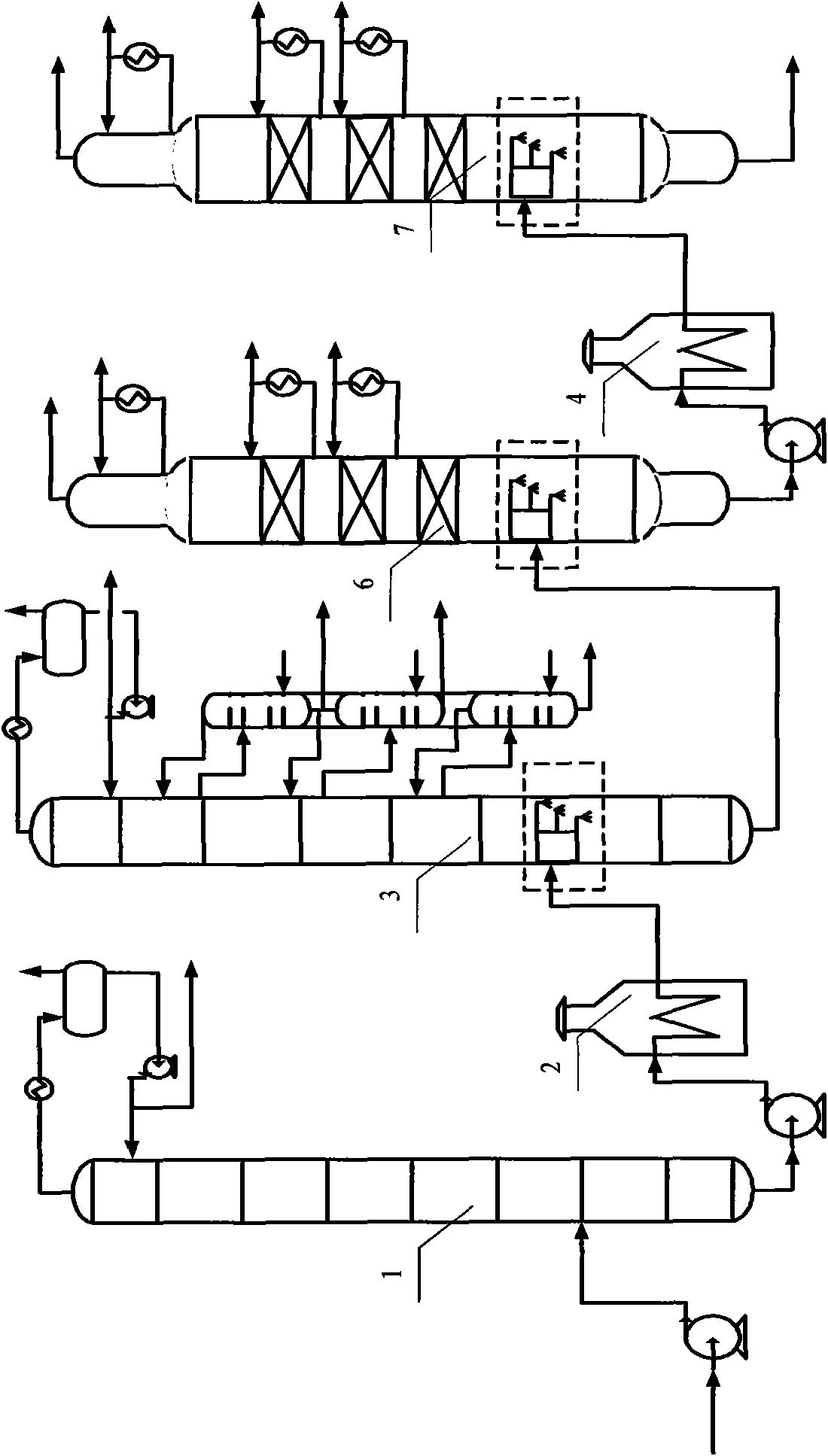

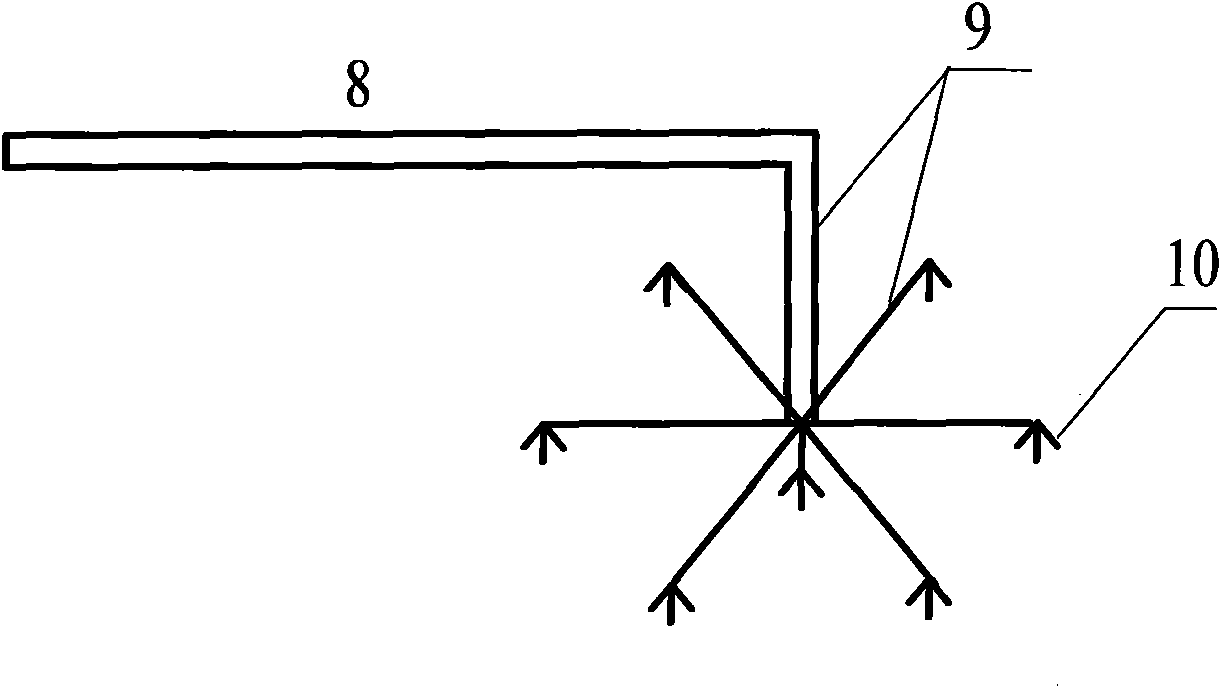

[0040] as attached figure 2 As shown, the desalted and dehydrated crude oil is heated to 205°C and enters the initial distillation tower 1, and the gasoline component is extracted from the top of the initial distillation tower. , sprayed into the atmospheric tower through the pressure feeding system, and atomized into small droplets. The pressure feeding system includes a flow distribution system and atomization equipment. The flow distribution system ensures that each atomization equipment has spray droplets. The atomization equipment is a swirling atomizing nozzle. The swirl core is placed in front of the nozzle. A single-hole plate is installed on the top of the swirl core. The swirled liquid is sprayed out through the hole to form a conical liquid film. The radial velocity and angular velocity, the friction caused by the speed difference between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com