Vacuum drying method for lithium battery cell

A technology of vacuum drying and lithium battery, which is used in drying solid materials, drying gas arrangement, drying solid materials without heating, etc., can solve the problems of low efficiency, increased cost, large energy consumption, etc. The effect of increasing the vaporization rate and increasing the vacuum degree of baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

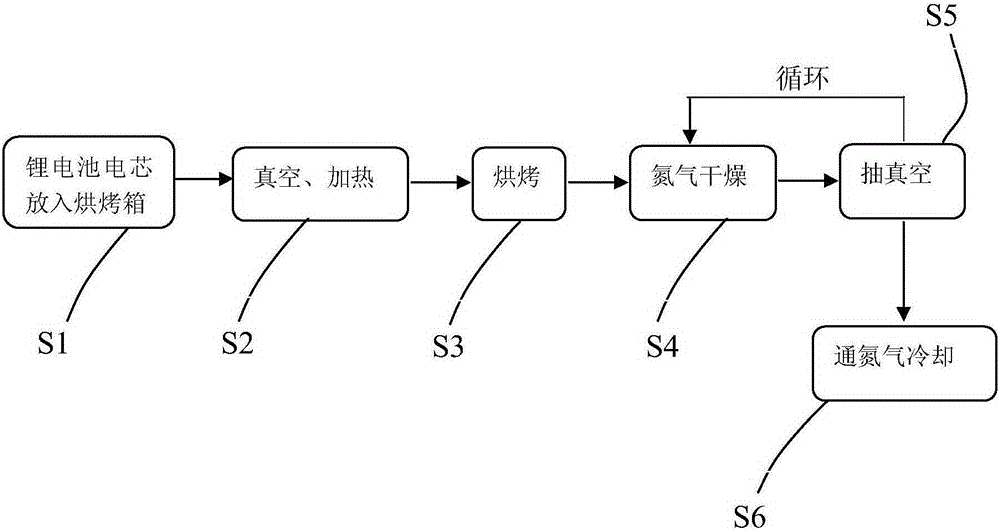

[0021] (1), put the lithium battery into the vacuum oven, close the oven door;

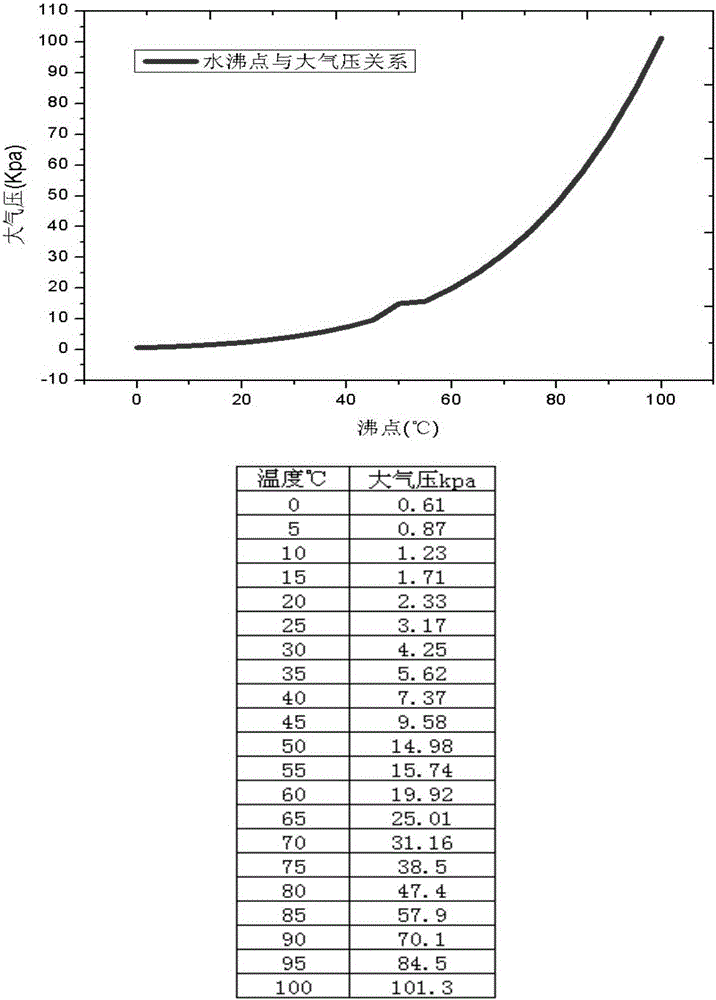

[0022] (2) Turn on the heating switch and heat up to 85°C; turn on the vacuum pump and evacuate to 0.2Kpa~0.3Kpa;

[0023] (3), keep constant vacuum degree, temperature, bake for 2 hours;

[0024] (4) Introduce dry nitrogen, unload the vacuum to normal pressure of 101.325Kpa, and keep the time of nitrogen inflow for 2min to 3min;

[0025] (5), vacuumize to 0.2Kpa~0.3Kpa, bake for 2 hours;

[0026] (6), feed dry nitrogen, unload the vacuum to normal pressure; cool down to below 60°C, and obtain the lithium battery cells that have been grilled. After the baking is completed, take out the battery cell and measure the moisture content of the pole piece.

Embodiment 2

[0028] (1), put the lithium battery into the vacuum oven, close the oven door;

[0029] (2) Turn on the heating switch and heat up to 85°C; turn on the vacuum pump and evacuate to 0.2Kpa~0.3Kpa;

[0030] (3), keep constant vacuum degree, temperature, bake for 2 hours;

[0031] (4) Introduce dry nitrogen, unload the vacuum to normal pressure of 101.325Kpa, and keep the time of nitrogen inflow for 2min to 3min;

[0032] (5), vacuumize to 0.2Kpa~0.3Kpa, bake for 2 hours;

[0033] (6) Introduce dry nitrogen, unload the vacuum to normal pressure 101.325Kpa, and keep the time of nitrogen inflow for 2min to 3min;

[0034] (7), vacuumize to 0.2Kpa~0.3Kpa, bake for 2 hours;

[0035] (8) Introduce dry nitrogen, unload the vacuum to normal pressure; cool down to below 60°C, and bake the lithium battery cells. After the baking is completed, take out the battery cell and measure the moisture content of the pole piece.

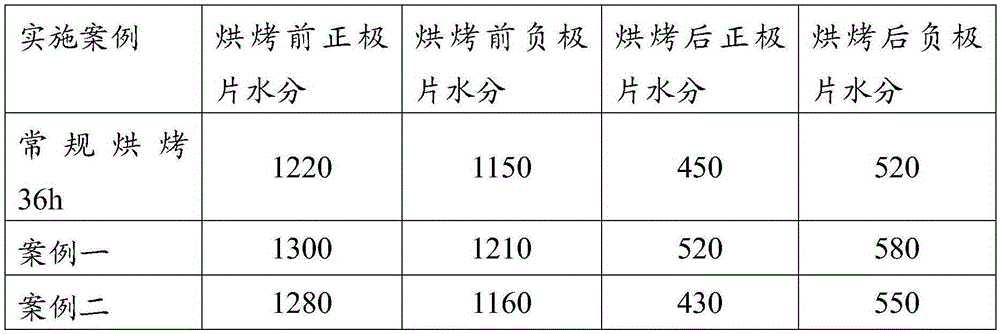

[0036] Embodiment one, embodiment two implementation data:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com