Method for preparing substrate with periodical structure

a technology of periodical structure and substrate, applied in the field of periodical structure preparation, can solve the problems of high manufacturing cost, low production capacity, high energy engraving process, etc., and achieve the effects of reducing the probability of substrate damage, uniform periodical structure, and simple and inexpensive way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

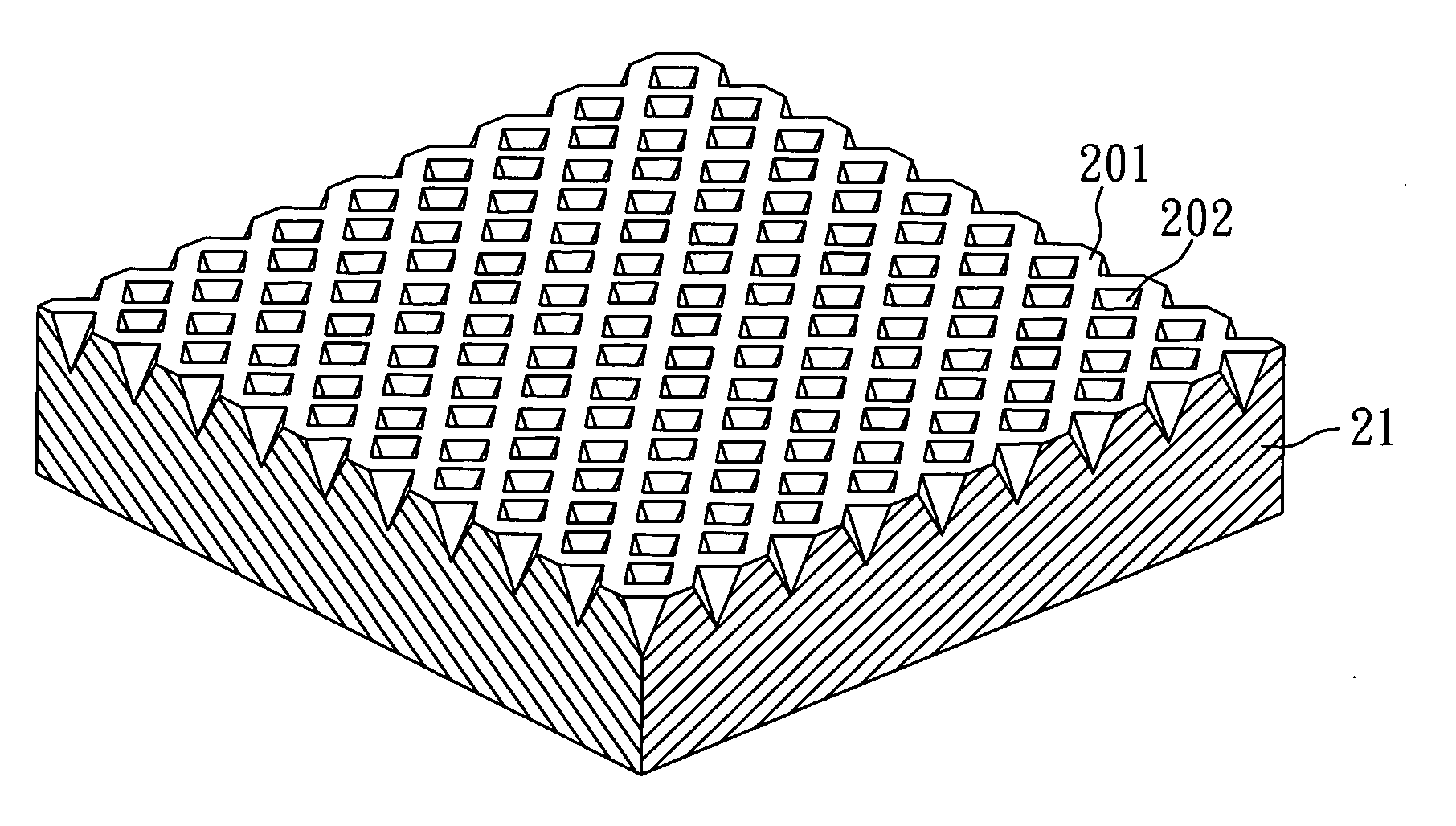

[0032]FIGS. 3A to 3F are cross-sectional views illustrating a process that nano-sized balls are arranged on a surface of a substrate in a preferred embodiment of the present invention. First, as shown in FIG. 3A, a substrate 21 is provided, and a colloid solution 25 is provided in a container 26, wherein the colloid solution 25 comprises plural nano-sized balls (not shown in the figure) and a surfactant (not shown in the figure). Next, the substrate 21 is placed in the container 26, and the substrate 21 is immersed in the colloid solution 25 entirely, as shown in FIG. 3B. After several minutes, the nano-sized balls 22 are arranged on the surface of the substrate 21 orderly to form a “nano-sized ball layer”, as shown in FIG. 3C. Then, a volatile solution 27 is added into the container 26 to evaporate the colloid solution 25, as shown in FIG. 3D. Finally, after the colloid solution 25 is evaporated completely, as shown in FIG. 3E, the substrate 21 is taken out from the container 26, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com