Solar zero-liquid-discharge sea water desalting plant and method

A discharge device and solar energy technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve the problems of small water production, low thermal efficiency and solar water production rate, and affect the fresh water recovery rate, so as to achieve the goal of water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

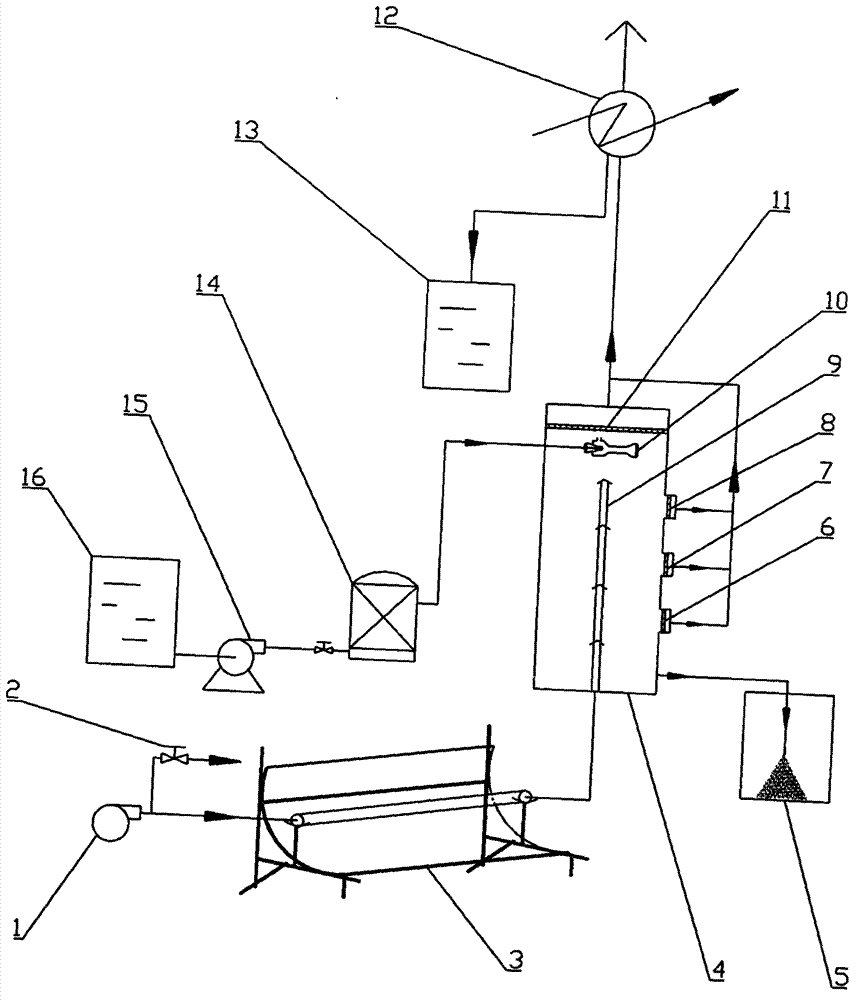

[0034]A solar zero liquid discharge seawater desalination device of the present invention comprises a hot air heating device composed of a fan 1, an air volume regulating valve 2 and a concentrating solar air heat collector 3; it is characterized in that: the original seawater storage tank 16, a booster pump 15. The filter 14 and the nozzle 10 form a pressure spray device. The pressure at the front end of the nozzle 10 before atomization is 0.5MPa; connected, the atomizing evaporator 4 is provided with a multi-outlet hot air distributor 9, and wet air outlets with screens 6, 7, 8, 11; the high-temperature saturated hot air coming out from the upper part of the atomizing evaporator is wet-saturated The fresh water condensed by the air condenser 12 enters the fresh water storage tank 13, and the solid crystal storage tank 5 is obtained from the outlet of the lower part of the atomization evaporator. , and then to nozzle 10.

Embodiment 2

[0036] In the solar zero liquid discharge seawater desalination method of the present invention, the raw seawater is pressurized by the raw seawater storage tank 16 through the booster pump 15 , passes through the micron filter 14 , and then reaches the nozzle 10 . The liquid droplets atomized by the nozzle 10 are in contact with the dry hot air at the outlet of the multi-outlet hot air distributor 9 multiple times during the evaporation process to realize multi-stage nano-evaporation.

[0037] Solar zero liquid discharge seawater desalination process: seawater with a salt content of 35000mg / L is pressurized to 0.6MPa by the original seawater storage tank 16 through the booster pump 15, passes through the filter 14 with a specification of 10 microns, and then reaches the nozzle 10. The median diameter of the atomized volume of the nozzle 10 is 120 μm, and the trough-type concentrating solar air is heated, and the air temperature at the 3 outlet is 265 ° C. After passing through...

Embodiment 3

[0039] 4m 2 A parabolic concentrating heat collection system with a horizontal focal length of 27.5mm, the heat receiving tube is a φ58 / 70 double-pass vacuum heat collection tube, and the air flow rate is 25m 3 / h, the air temperature rises from the ambient temperature of 23°C to 260°C, the seawater at 20°C is atomized at a flow rate of 3L / h under a pressure of 0.4MPa, and the outlet humid air temperature is controlled at 75°C, the water in the seawater is completely evaporated, and crystallized salt is obtained 100g, while also obtaining 3L of fresh water with a salt content of 300mg / L.

[0040] This embodiment has the solar energy zero liquid discharge seawater desalination device and method, the process is simple, no need to add any chemical additives, and zero liquid discharge is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com