Preparation method of hydrophobic modified graphene oxide reverse osmosis membrane

A technology of hydrophobic modification and reverse osmosis membrane, which is applied in chemical instruments and methods, reverse osmosis, semi-permeable membrane separation, etc. It can solve the problems of easy agglomeration and low GO content, and achieve the goal of hindering agglomeration tendency, high flux and high Effect of Salt Rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

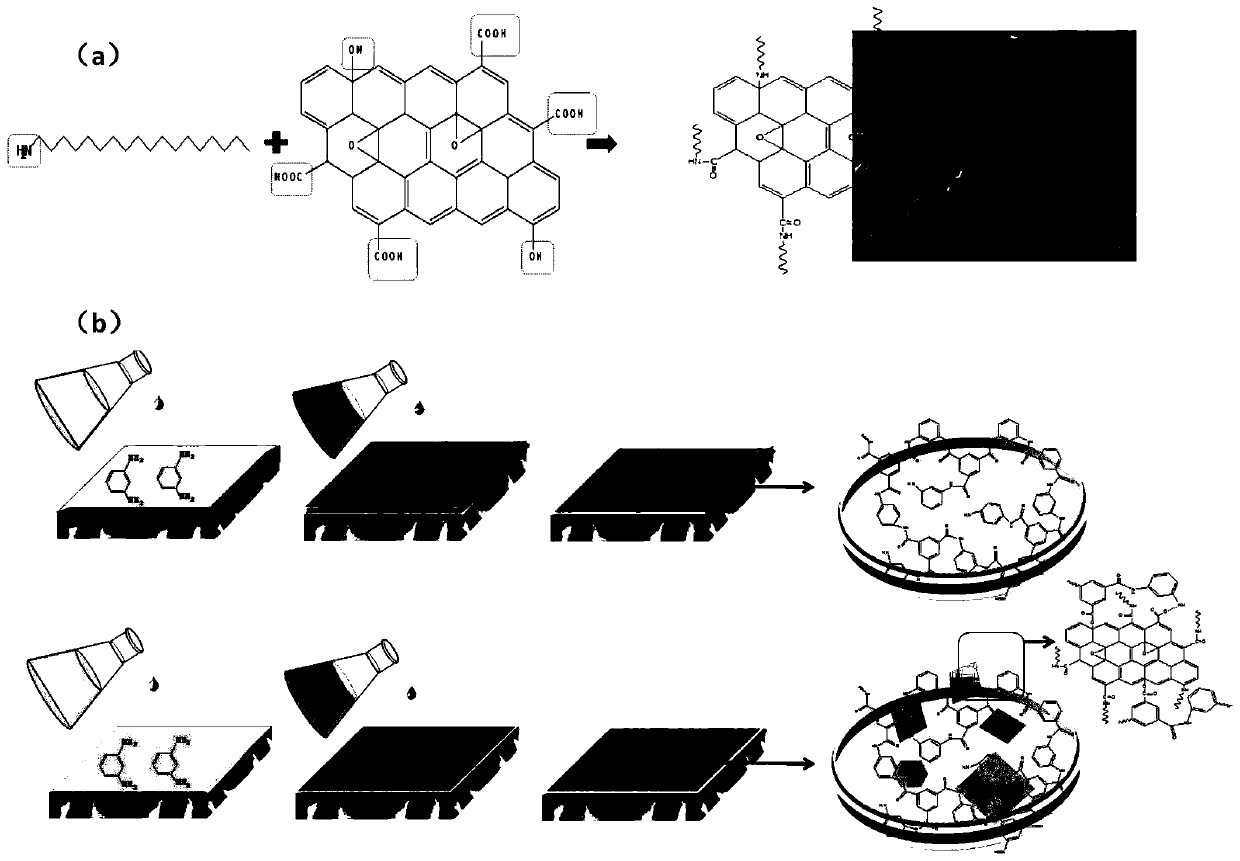

Method used

Image

Examples

Embodiment 1

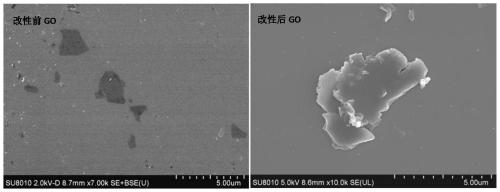

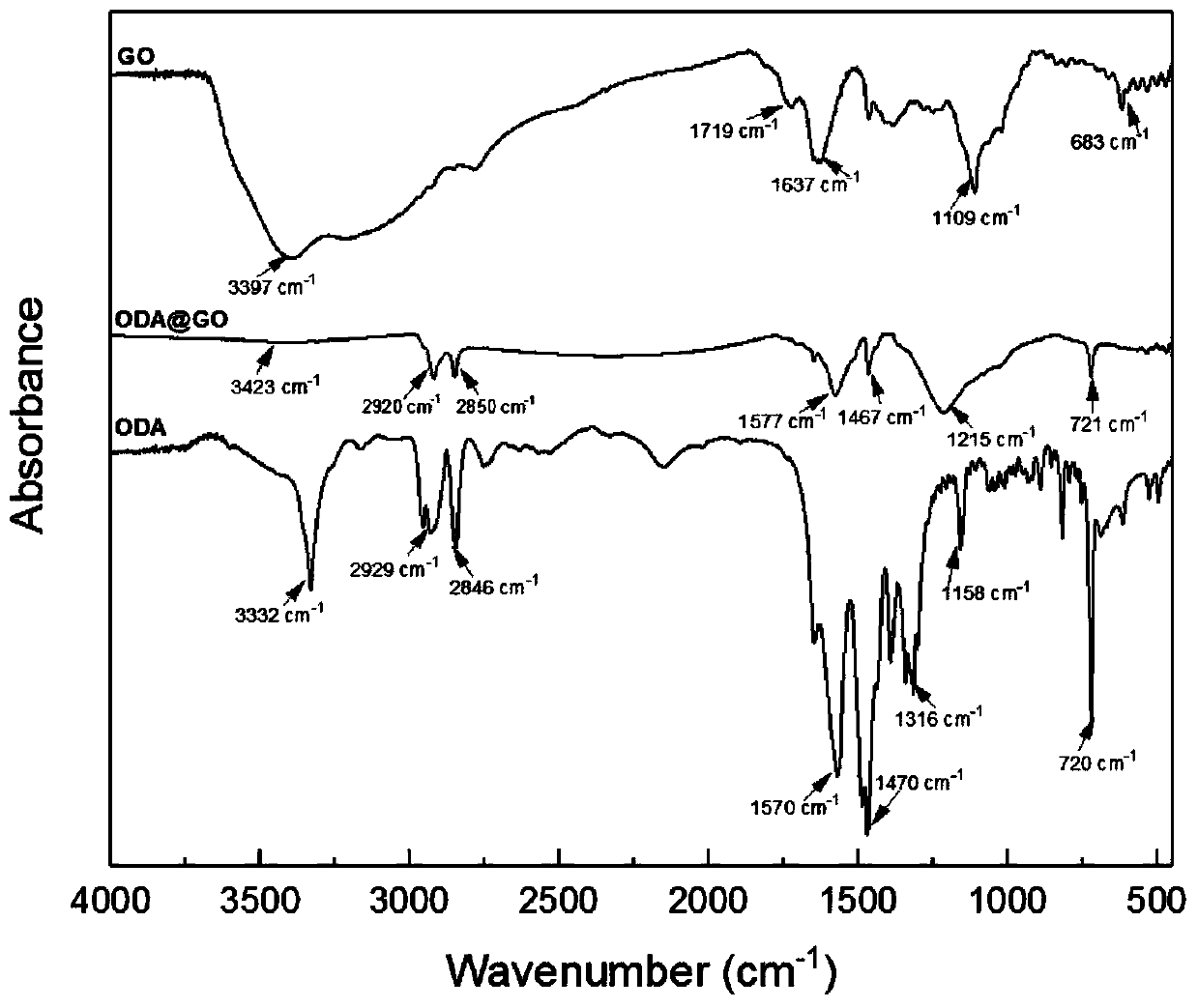

[0042] According to the condition that the mass ratio of octadecylamine to graphene oxide is 3:2, add 10 mg / mL octadecylamine ethanol solution (water bath ultrasonication for 10 min) to 2 mg / mL GO suspension (water bath ultrasonication for 1 h), stir for 5 min and place Reaction in the reactor at 90°C for 24h. Rinse with ethanol, and after centrifugation, take the precipitate and place it in a vacuum drying oven, and dry it at 50°C for 24h. The obtained black solid powder is octadecylamine-modified graphene oxide.

Embodiment 2

[0044] 1) Prepare MPD aqueous solution (2wt%), and prepare TMC n-hexane solution (0.1wt%). Wherein, 4wt% camphorsulfonic acid (CSA) and an appropriate amount of triethylamine buffer system are added to 2wt% MPD aqueous phase to make pH=10.

[0045] 2) According to the concentration ratio of 0.001wt%, the octadecylamine-modified GO prepared according to the method of Example 1 was added to the organic solution of 0.1wt% TMC, and the water bath was ultrasonicated for one hour at room temperature.

[0046]3) Select a PSF base film with no scratches and defects on the surface, clean it and tighten it, cut it and fix it, clean it again and place it on the operating table, and put the non-woven fabric layer outward and dry it until no water drops remain on the surface of the film.

[0047] 4) Pour the MPD aqueous solution prepared in step 1) into the surface of the prepared PSF base film, and let the entire film surface be submerged. After standing for 2 minutes, pour out the excess...

Embodiment 3

[0051] Referring to Example 2, the only difference is that the concentration of modified GO in the organic solution of TMC prepared in step 2) is 0.003wt%, and a mixed matrix reverse osmosis membrane is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com