High-flux high-desalination-rate mixed matrix reverse osmosis membrane, and preparation method and application thereof

A mixed matrix, reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of poor compatibility of inorganic nanomaterials, influence on operation stability, interface defects, etc. Flux, the effect of reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

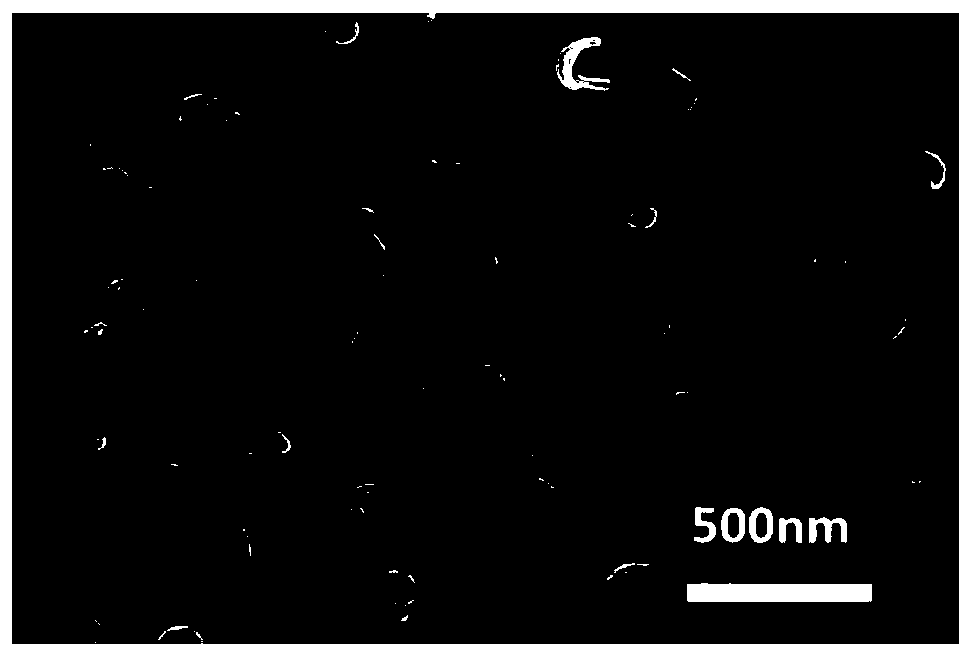

[0041] Soak the polysulfone supporting membrane with a size of 20cm×10cm in 50 ml of polyamine aqueous phase solution for 2 minutes, which contains 2wt% m-phenylenediamine, 0.15wt% sodium dodecylsulfonate , 4wt% camphorsulfonic acid, 2wt% triethylamine, after removing excess solution, dry the membrane surface at room temperature. After the membrane surface is dry, soak the above-mentioned polysulfone support membrane in 50 ml of 0.15wt% trimesoyl chloride n-hexane solution to allow interfacial polymerization. The soaking time is 40 seconds, then remove excess solution, and dry in the shade at room temperature Afterwards, heat treatment in a 60°C oven for 5 minutes to obtain No. 1 film. Membrane No. 1 is the control group prepared by the traditional process, according to figure 1 It can be known that the reverse osmosis membrane prepared by the traditional process has a typical nodular structure on the surface of the membrane, and the roughness is relatively large.

example 2

[0043] Add 30 g (about 0.1 mol) PEG600 and 1 g (about 0.006 mol) p-toluenesulfonic acid into a 250 ml three-necked flask. Dissolve 19.2g (0.1mol) of 1,2,4-trimesic anhydride in 50ml of tetrahydrofuran, and slowly drop it into a three-necked flask through a 100ml constant pressure dropping funnel within 2h under stirring at 60°C, and continue stirring for 6h after the addition is complete . The three-necked flask was connected to a mechanical stirrer, nitrogen gas was fed through a water separator, the temperature was raised to 100°C, and the reaction was carried out for 1 hour, then the temperature was raised to 120°C, and the reaction was carried out for 1 hour. After that, 30 ml of DMF was added to the three-necked flask and the temperature was raised to 140°C for 4 hours to obtain the initial product. After the primary product was cooled, it was dialyzed in acetone for 2 days using a dialysis bag with a molecular weight cut-off of 3500, and the dialysis product was dried to...

example 3

[0046] HBPAC preparation process is consistent with example 2.

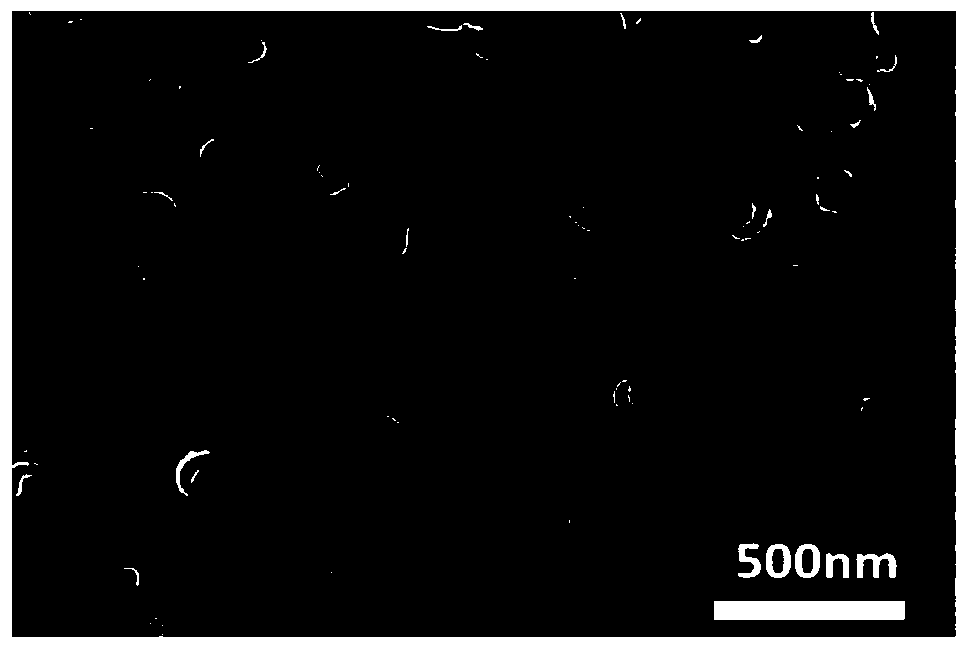

[0047] Soak the polysulfone supporting membrane with a size of 20cm×10cm in 50 milliliters of polyamine aqueous phase solution for 2 minutes, which contains 2wt% m-phenylenediamine, 0.15wt% sodium dodecylsulfonate, 4wt% camphorsulfonic acid , 2wt% triethylamine. After removing excess solution, dry the membrane surface in the shade at room temperature. After the membrane surface is dry, soak the above-mentioned polysulfone support membrane in 50 ml of n-hexane solution of 0.005wt% HBPAC and 10v / v% trichloromethane to carry out the first interfacial polymerization. The soaking time is 10 seconds to remove excess After solution, dry in the shade at room temperature. After the membrane surface is dried, the polysulfone supporting membrane is soaked in 50 milliliters of 0.15wt% trimesoyl chloride n-hexane solution to make it carry out the second interfacial polymerization. The soaking time is 40 seconds, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com