Hydrophobically modified distillation membrane material of high throughout and high salt rejection rate and application thereof

A technology of hydrophobic modification and modified materials, which is applied in the field of membrane materials, can solve the problems of low water flux and achieve high stability, uniform modification process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

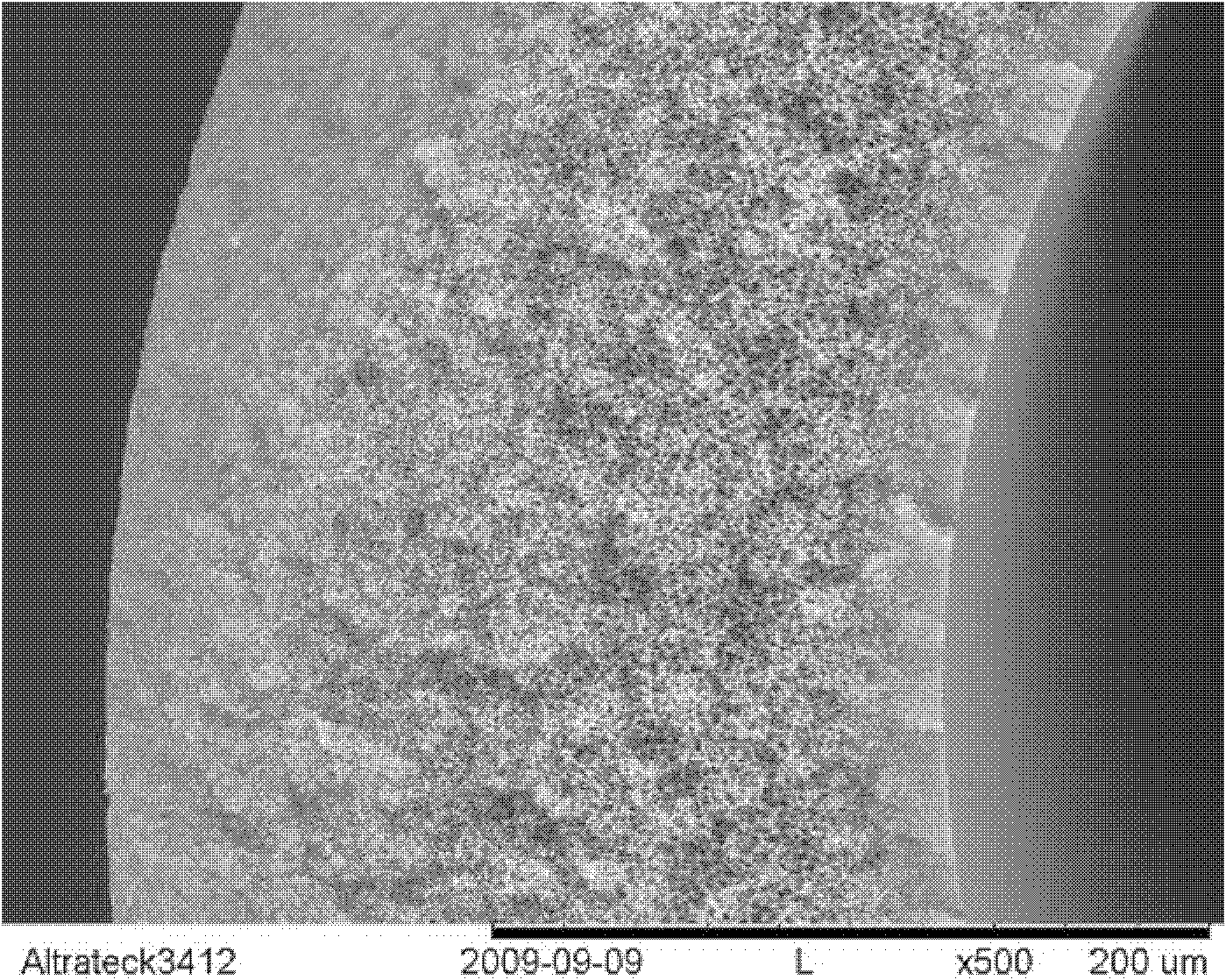

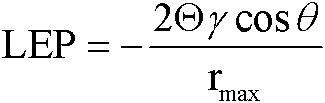

Embodiment 1

[0038] The asymmetric hydrophilic PES hollow fiber membrane (average pore size of 50 nm, contact angle of 0°) was placed in an oven at 40°C for 60 minutes, and then the membrane was placed in the plasma chamber, and the CF was used first. 4 (95%) and O 2 (5%) Plasma cleans and etches the film surface into a rough surface. The processing power is 200w, the time is 20min, and the pressure in the chamber is 180mTorr to obtain the etched film surface. Then pass into CF 4 Gas, when the pressure in the cavity reaches 200mTorr, the discharge generates plasma, the power is 100w, the time is 5min, and the pressure in the cavity is 300mTorr. After modification, the contact angle of the outer surface of the membrane was 150°, and the contact angle of the inner surface was 100°. The modified membranes were loaded into a module of a direct contact membrane distillation (DCMD) unit for testing. The feed liquid is 4 wt% NaCl aqueous solution, and the permeate is deionized water. When the...

Embodiment 2

[0040] As described in Example 1, the asymmetric hydrophilic PES hollow fiber membrane was dried in an oven at 50°C for 40 minutes, and placed in a plasma chamber after drying. The surface of the membrane was first etched and cleaned with Ar plasma. The treatment power was 300w, and the time For 30min, the pressure in the cavity is 200mTorr, to obtain the activated membrane surface, and then pass the C 4 F 8 Gas, when the pressure in the cavity reaches 200mTorr, the discharge generates plasma, the power is 100w, the time is 10min, and the pressure in the cavity is 200mTor. After modification, the contact angle of the outer surface of the membrane was 153°, and the contact angle of the inner surface was 102°. The modified membrane was used for the vacuum membrane distillation test, the feed liquid was 4wt% NaCl aqueous solution, the vacuum degree was 0.05MPa, and the flux was 78.8kg m when the feed liquid inlet temperature was 74.1°C and the permeate side inlet temperature was...

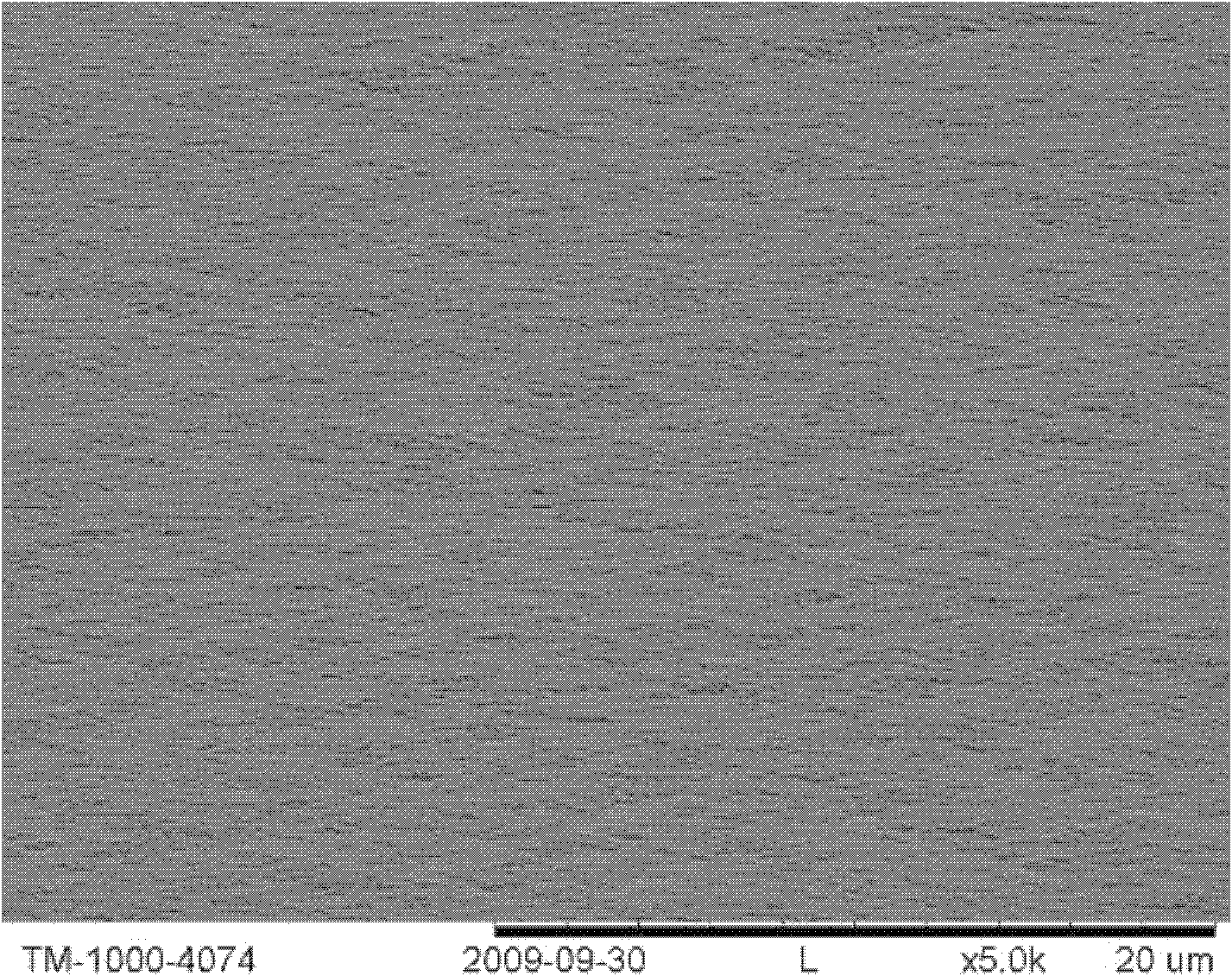

Embodiment 3

[0042] The asymmetric hydrophilic PES flat membrane (average pore size 150 nm, contact angle 0°) was placed in a 40°C oven to dry for 60 min, and then placed in a plasma chamber after drying, using O 2 The plasma will clean and activate the membrane surface, the processing power is 300w, the time is 10min, the pressure in the chamber is 200mTorr, take out, put the membrane in 0.5mM OTS solution, react at 10°C for 24h, take out the membrane and dry. After modification, the surface contact angle of the membrane was 136°, and the bottom surface contact angle was 130°. The modified membrane was subjected to the DCMD test as described in Example 1. When the inlet temperature of the feed liquid was 74.0 °C and the inlet temperature of the permeate side was 19.0 °C, the flux was 65.6 kg m -2 h -1 , after continuous operation for 10h, the flux did not decrease, and the retention rate was 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com