Sulfhydrylation-modified TRIES separating membrane and preparation method and purpose thereof

A technology of separation membrane and thiolization, which is applied in chemical instruments and methods, semi-permeable membrane separation, membrane, etc., can solve the problems of low separation performance of inorganic reverse osmosis membranes, achieve improved water flux, easy passage, and improved salt interception rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

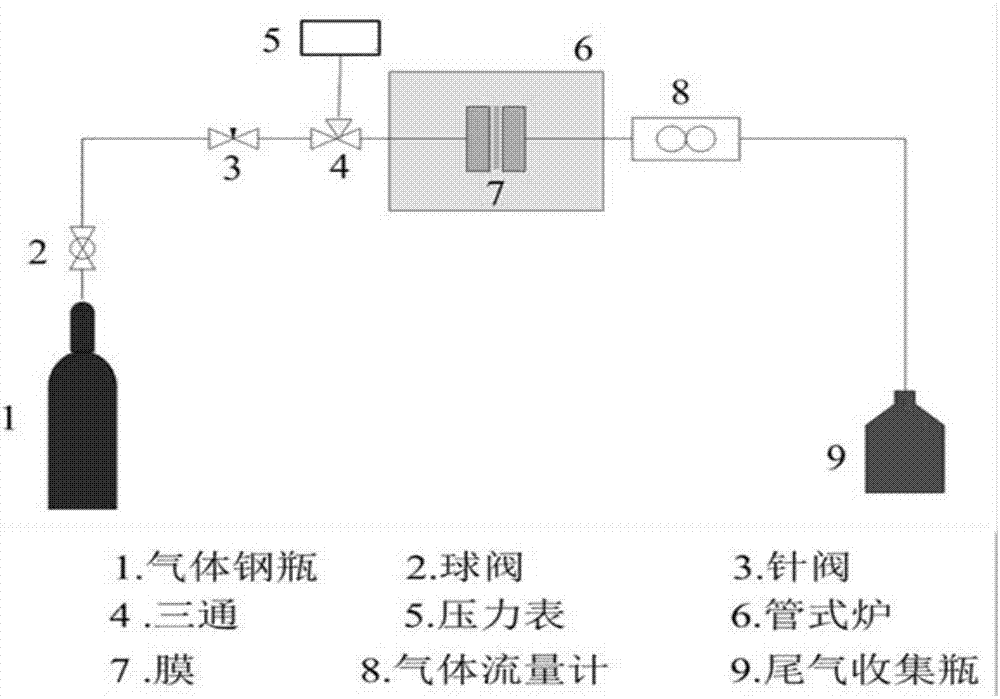

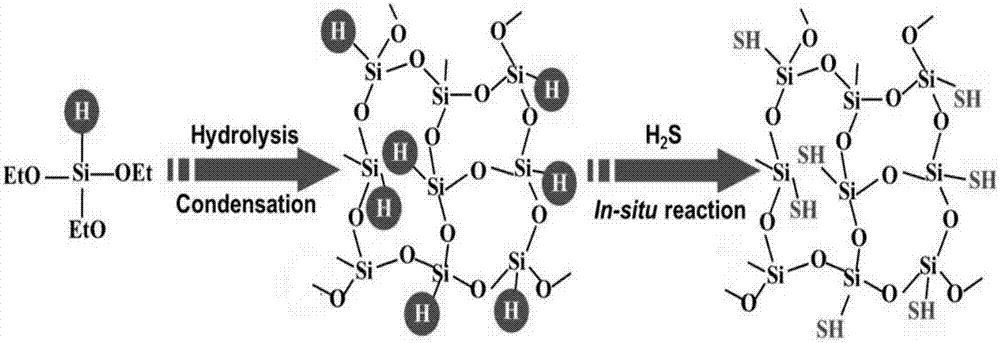

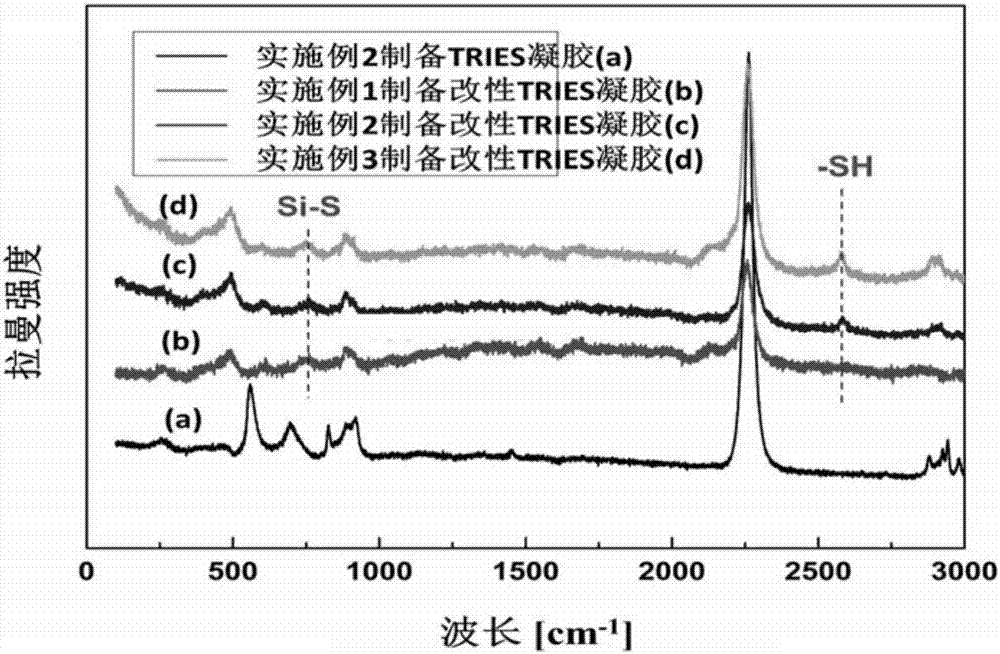

[0023] 1. Under the condition of continuous stirring in a water bath at 25°C, add 1g of triethoxysilane to 22.67g of isopropanol to disperse evenly, then add 26.33g of deionized water to disperse evenly, and finally add 0.022g of HCl solution After reacting for 2h, the TRIES sol was prepared, which was coated on α-Al 2 o 3 Material support diaphragm, at 400°C N 2 Calcined under the atmosphere to prepare the TRIES separation membrane;

[0024] 2. Put the TRIES separation membrane prepared in step 1 in a tube furnace, and pass H at 400°C 2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ mercapto-modification, modified for 1 hour, to prepare mercapto-modified TRIES separation membrane;

[0025] 3. Put the TRIES sol prepared in step 1 in a tube furnace, 2 Calcined under the atmosphere to prepare the TRIES gel, and pass H at 400°C 2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ thiol modification, modified for 1 hour, prepared mercapto-modified TRIES ...

Embodiment 2

[0027] 1. Under the condition of continuous stirring in a water bath at 25°C, add 1g of triethoxysilane to 22.67g of isopropanol to disperse evenly, then add 26.33g of deionized water to disperse evenly, and finally add 0.022g of HCl solution After reacting for 2h, the TRIES sol was prepared, which was coated on α-Al 2 o 3 Material support diaphragm, at 500°C N 2 Calcined under the atmosphere to prepare the TRIES separation membrane;

[0028] 2. Put the TRIES separation membrane prepared in step 1 in a tube furnace, and pass H at 500°C 2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ mercapto-modification, modified for 1 hour, to prepare mercapto-modified TRIES separation membrane;

[0029] 3. Put the TRIES sol prepared in step 1 in a tube furnace, 2 Calcined under the atmosphere to prepare the TRIES gel, and pass H at 500°C 2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ thiol modification, modified for 1 hour, prepared mercapto-modified TRIES ...

Embodiment 3

[0031] 1. Under the condition of continuous stirring in a water bath at 25°C, add 1g of triethoxysilane to 22.67g of isopropanol to disperse evenly, then add 26.33g of deionized water to disperse evenly, and finally add 0.022g of HCl solution After reacting for 2h, the TRIES sol was prepared, which was coated on α-Al 2 o 3 Material support diaphragm, at 600°C N 2 Calcined under the atmosphere to prepare the TRIES separation membrane;

[0032] 2. Put the TRIES separation membrane prepared in step 1 in a tube furnace, and pass H at 600°C 2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ mercapto-modification, modified for 1 hour, to prepare mercapto-modified TRIES separation membrane;

[0033] 3. Put the TRIES sol prepared in step 1 in a tube furnace, 2 Calcined under the atmosphere to prepare the TRIES gel, and pass H at 600°C2 S molar concentration of 10% H 2 S / H 2 Mixed gas, in-situ thiol modification, modified for 1 hour, prepared mercapto-modified TRIES ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com