Metal-organic framework nanosheet modified forward osmosis film and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of copper-terephthalic acid metal-organic framework nanosheets: 10 g / L concentration of terephthalic acid (McLean) was dissolved in acetonitrile (Aladdin) and N,N-dimethylformamide (Aladdin) 2: Obtain solution A in the solvent of 1, and solution B is the solvent of acetonitrile and N, N-dimethylformamide 1:1, and 10g / L copper nitrate trihydrate (McLean) is dissolved in acetonitrile and N, N-dimethylformamide Solution C was obtained in the solvent of methyl formamide 1:2, and slowly added in the test tube in the order of solutions A, B, and C at a ratio of 3:2:3 to avoid complete mixing, and then stood at 40°C for 24 hours , and the precipitates are copper-terephthalic acid metal organic framework nanosheets.

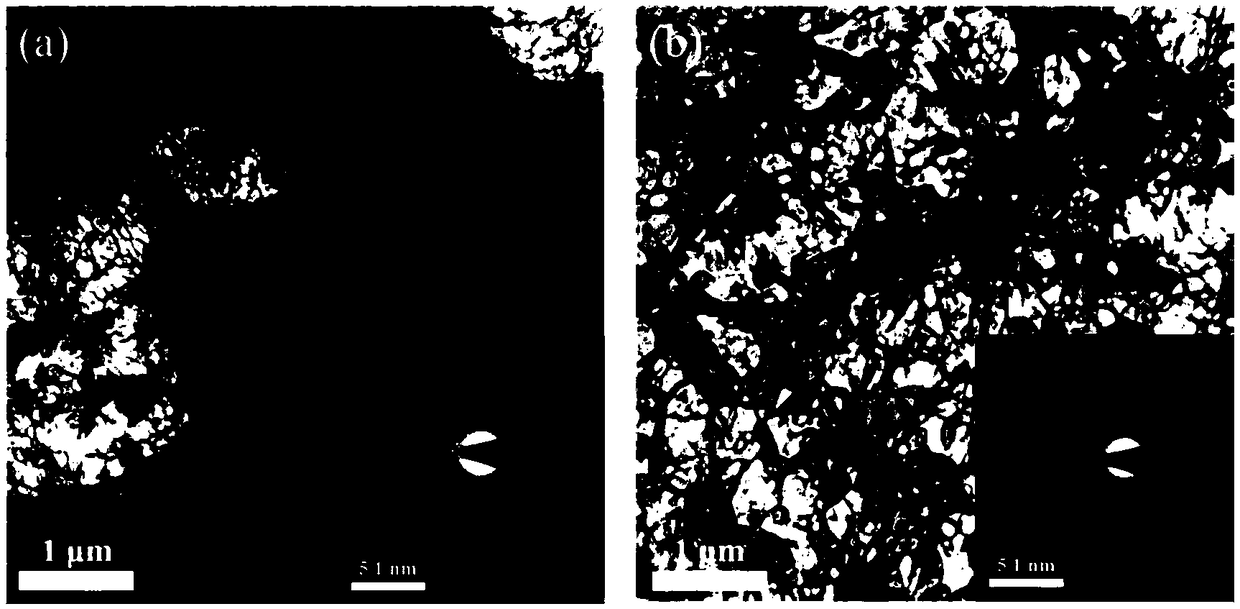

[0040] Material characterization: After washing the nanosheets with N,N-dimethylformamide and dichloromethane (Aladdin) three times, disperse them in dichloromethane, ultrasonically disperse them for 30 minutes, then disperse the nanosheets-dichloromet...

Embodiment 2

[0043]Preparation of the support layer of the forward osmosis membrane: the composition of the casting solution of the support layer is 12wt% polyethersulfone (BASF), no porogen is added, dissolved in N,N-dimethylformamide; after 8 hours of dissolution at 40°C , put it in a 40°C oven for 1 day to defoam, form a uniform mixed solution, pour it onto a glass plate, scrape the film with a scraper with a height of 200 μm, and then place it in a deionized hydrogel bath for phase Transformation, the membrane automatically falls off from the glass plate, and the support layer for the forward osmosis membrane can be obtained.

Embodiment 3

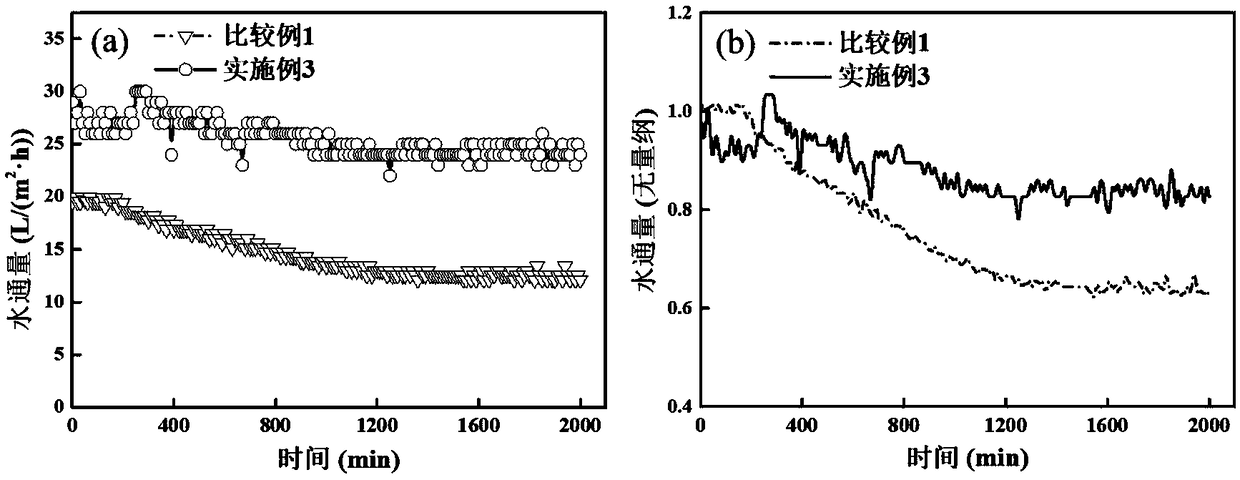

[0045] Preparation of copper-terephthalic acid metal-organic framework nanosheets modified forward osmosis membrane: metal-organic framework nanosheets were added to 0.05wt% trimesoyl chloride (Aladdin) in n-hexane at a ratio of 0.12wt / v% (Aladdin) solution, ultrasonic 30min to form a uniformly dispersed solution. Treat the support layer in 2.0wt% m-phenylenediamine (Aladdin) aqueous solution for 2min, remove excess droplets on the surface of the support layer with an air knife, and then treat the surface of the support layer with trimesoyl chloride-n-hexane solution of nanosheets for 30s , Pour off the solution, and finally treat the membrane in hot water at 80°C for 1 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com