Preparation method of hydrophilic anti-pollution aromatic polyamide reverse-osmosis membrane

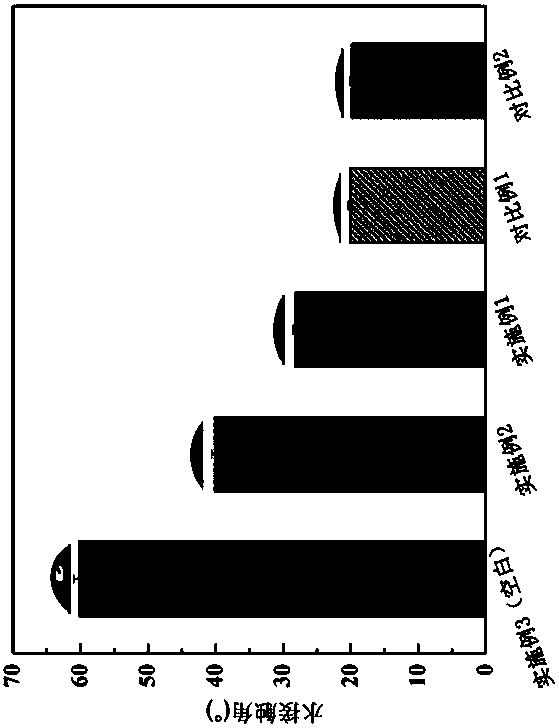

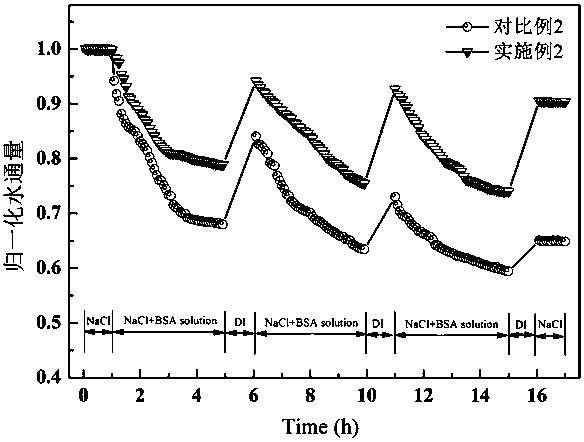

A technology of aromatic polyamide and reverse osmosis membrane, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of anti-pollution characteristics, flux and interception performance, and achieve good chemical stability properties and physical stability, overall roughness reduction, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Embodiment 1: This embodiment records a method for preparing a hydrophilic anti-pollution aromatic polyamide reverse osmosis membrane. The steps of the preparation method are as follows:

[0019] (1) The polysulfone (PSf) base membrane was soaked in deionized water for 24 h, rinsed, dried, fixed in a polytetrafluoroethylene frame, and m-phenylenediamine (MPD) and dimethyl diamine were poured on its surface. Aqueous solution of allyl ammonium chloride (DADMAC), then let it stand for 5~10 minutes, and the excess aqueous solution was removed by blowing with an air knife;

[0020] (2) Pour the n-hexane solution of trimesoyl chloride (TMC) into the surface of the membrane obtained in (1), and carry out interfacial polymerization at room temperature for 60 s;

[0021] (3) Pour the aqueous solution of hydrophilic olefin monomer into the surface of the membrane obtained in (2), place the membrane fixed on the polytetrafluoroethylene frame together with the frame in a glass irra...

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation method of a hydrophilic anti-pollution aromatic polyamide reverse osmosis membrane described in specific embodiment one, in step (1), the mass percentage of m-phenylenediamine is 0.1%~3 %, the mass percentage of dimethyl diallyl ammonium chloride is 0.1%~3%.

specific Embodiment approach 3

[0025] Specific embodiment three: the preparation method of a hydrophilic anti-pollution aromatic polyamide reverse osmosis membrane described in specific embodiment one, in step (2), the mass volume ratio of trimesoyl chloride to n-hexane is 0.1~0.5g: 500mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com