High-temperature resistance polyamide composite membrane and preparation method thereof

A composite membrane and polyamide technology, which is applied in the field of water treatment, can solve the problems of loss of desalination performance of composite membrane, low operating temperature of polyamide composite membrane, waste of large energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

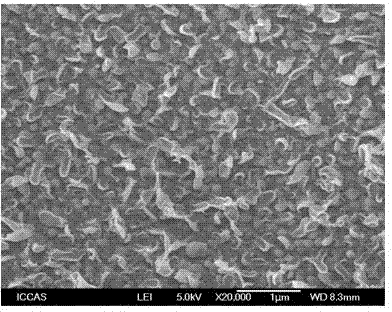

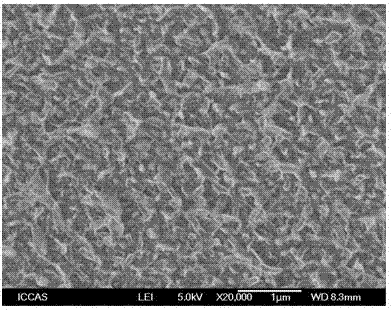

Image

Examples

Embodiment 1

[0018] Embodiment 1: prepare polyamide composite membrane according to the following steps:

[0019] Step 1: Prepare a porous membrane for use: Weigh 8g of polyether sulfone ketone (PPESK), 72g of polysulfone resin (PSF), 370g of N-methylpyrrolidone (NMP), polyethylene glycol 200 (PEG200) 50g, mix and prepare 500g solution. Stir at 70°C for 6 hours to prepare a uniformly dispersed casting solution. After the casting liquid is filtered and degassed, it is evenly coated on the non-woven fabric on a film scraping machine, with a wet film thickness of 150 μm. After evaporating at room temperature for 3 seconds, it is immersed in ultra-pure water at 18°C to gel and solidify to form a film. , the membrane was treated in water at 70°C for 5 minutes to obtain a porous membrane, which was stored in pure water at 25°C until use.

[0020] Step 2: Prepare two polymerized monomer solutions for use: Weigh 160g of m-phenylenediamine, 88g of triethylamine, 184g of camphorsulfonic acid, 80...

Embodiment 2

[0022] Embodiment 2: prepare polyamide composite membrane according to the following steps:

[0023] Step 1: Prepare porous membrane for use: Weigh 16g of polyethersulfone ketone (PPESK), 64g of polysulfone resin (PSF), 370g of N-methylpyrrolidone (NMP), polyethylene glycol 200 (PEG200) 50g, mix and prepare 500g solution. Stir at 70°C for 6 hours to prepare a uniformly dispersed casting solution. After the casting liquid is filtered and degassed, it is evenly coated on the non-woven fabric on a film scraping machine, with a wet film thickness of 150 μm. After evaporating at room temperature for 3 seconds, it is immersed in ultra-pure water at 18°C to gel and solidify to form a film. , the membrane was treated in water at 70°C for 5 minutes to obtain a porous membrane, which was stored in pure water at 25°C until use.

[0024] Step 2: Preparation of polymerized monomer solution: same as in Example 1.

[0025] Step 3: Preparation of polyamide composite membrane: Same as Exa...

Embodiment 3

[0026] Embodiment 3: prepare polyamide composite membrane according to the following steps:

[0027] Step 1: Prepare porous membrane for use: Weigh 24g of polyethersulfone ketone (PPESK), 56g of polysulfone resin (PSF), 370g of N-methylpyrrolidone (NMP), polyethylene glycol 200 (PEG200) 50g, mix and prepare 500g solution. Stir at 70°C for 6 hours to prepare a uniformly dispersed casting solution. After the casting solution is filtered and degassed, it is evenly coated on the non-woven fabric on a film scraping machine. The wet film thickness is 150 μm. After evaporating at room temperature for 3 seconds, it is immersed in ultrapure water at 18 ° C to form a gel and solidify the film. The membrane was treated in water at 70°C for 5 minutes, and stored in pure water at 25°C until use.

[0028] Step 2: Preparation of polymerized monomer solution: same as in Example 1.

[0029] Step 3: Preparation of polyamide composite membrane: Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com