Preparation method of composite forward osmosis membrane with Turing structure

A forward osmosis membrane, Turing's technology, applied in the field of membrane technology and water treatment, can solve the problems that cannot be widely used, and achieve the effect of low price and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

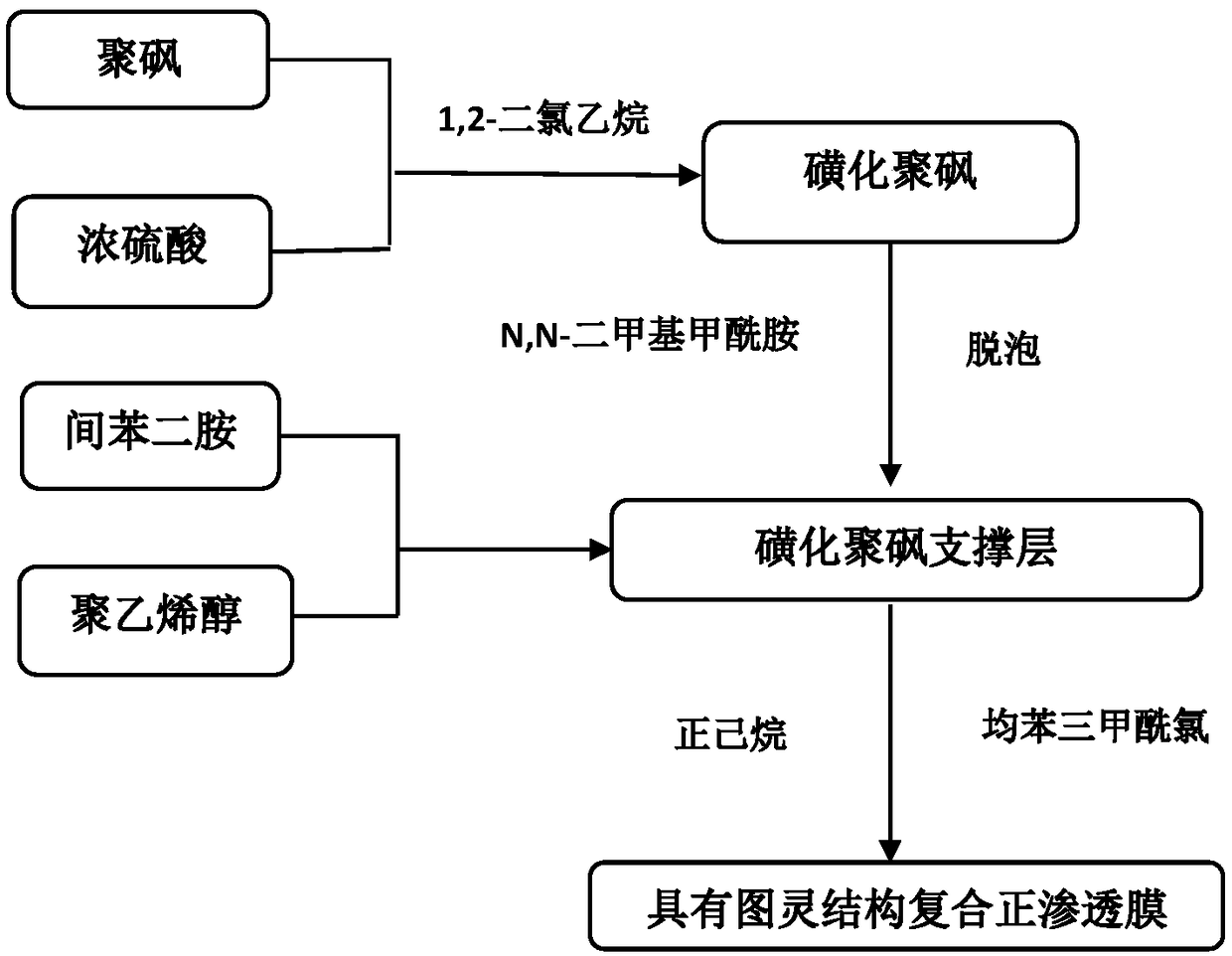

[0030] Such as figure 1 A kind of preparation method of the composite forward osmosis membrane with Turing structure that the shown invention proposes, comprises the following steps:

[0031] (1) Preparation of sulfonated polysulfone, the specific process is: (1a) polysulfone is added in 1,2-dichloroethane, and stirred in a round-bottomed flask until polysulfone and 1,2-dichloroethane are completely Dissolving to form a uniform and stable solution, the solid-to-liquid ratio of polysulfone to 1,2-dichloroethane is 0.1g:1mL~0.5g:1mL;

[0032] (1b) Slowly drop concentrated sulfuric acid with a mass percentage concentration of 70-80% into a uniform stable solution to form a mixed solution, the volume ratio of the concentrated sulfuric acid to the uniform stable solution is 0.25:1-0.75:1;

[0033] (1c) After stirring the mixed solution at 23-25°C for 5-8 hours, pour out 1,2-dichloroethane and excess concentrated sulfuric acid, and then deionize the solid matter attached to the bot...

Embodiment 1

[0044] To prepare a composite forward osmosis membrane with a Turing structure, the specific process is as follows:

[0045] (1) The preparation of sulfonated polysulfone, the specific process is: (a) take 0.2 g of polysulfone, add polysulfone into 1,2-dichloroethane, stir in a round bottom flask until polysulfone and 1,2 -Dichloroethane is completely dissolved to form a uniform and stable solution, the solid-to-liquid ratio of the polysulfone to 1,2-dichloroethane is 0.1g:1mL; (b) Slowly drop concentrated sulfuric acid into the uniform and stable solution to form For the mixed solution, the volume ratio of the concentrated sulfuric acid to the uniform stable solution is 0.25:1, and the concentrated sulfuric acid mass percentage concentration used is 70%; (c) after stirring the mixed solution at 23° C. for 5 h, pour out 1 , 2-dichloroethane and excess concentrated sulfuric acid, and then wash the solid matter adhering to the bottom of the round-bottomed flask with deionized wa...

Embodiment 2

[0051] To prepare a composite forward osmosis membrane with a Turing structure, the specific process is as follows:

[0052] (1) The preparation of sulfonated polysulfone, the specific process is: (a) take polysulfone 0.4g, add polysulfone in 1,2-dichloroethane, stir in the round bottom flask until polysulfone and 1,2 -Dichloroethane is completely dissolved to form a uniform and stable solution, the solid-to-liquid ratio of the polysulfone to 1,2-dichloroethane is 0.3g:1mL; (b) Slowly drop concentrated sulfuric acid into the uniform and stable solution to form For the mixed solution, the volume ratio of the concentrated sulfuric acid to the homogeneous stable solution is 0.5:1, and the mass percent concentration of the concentrated sulfuric acid used is 75%; (c) after stirring the mixed solution at 24°C for 6.5h, pour it out 1,2-Dichloroethane and excess concentrated sulfuric acid, and then wash the solid matter attached to the bottom of the round-bottomed flask with deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com