Method used for monitoring temperature control device of dies of injection molding machine or die-casting machine

A technology for temperature adjustment devices and die-casting machines, which is applied in the direction of measuring the rate of increase and deceleration of fluids, and using liquid/vacuum degrees for liquid tightness measurement, etc., which can solve the problems of inability to distinguish between pressure changes and fluid losses, and reduce space requirements , the effect of omitting costs

Active Publication Date: 2013-07-03

ENGEL AUSTRIA

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that only extremely large fluid losses can be identified

Cannot distinguish between intentional pressure changes and fluid loss in the circulation system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

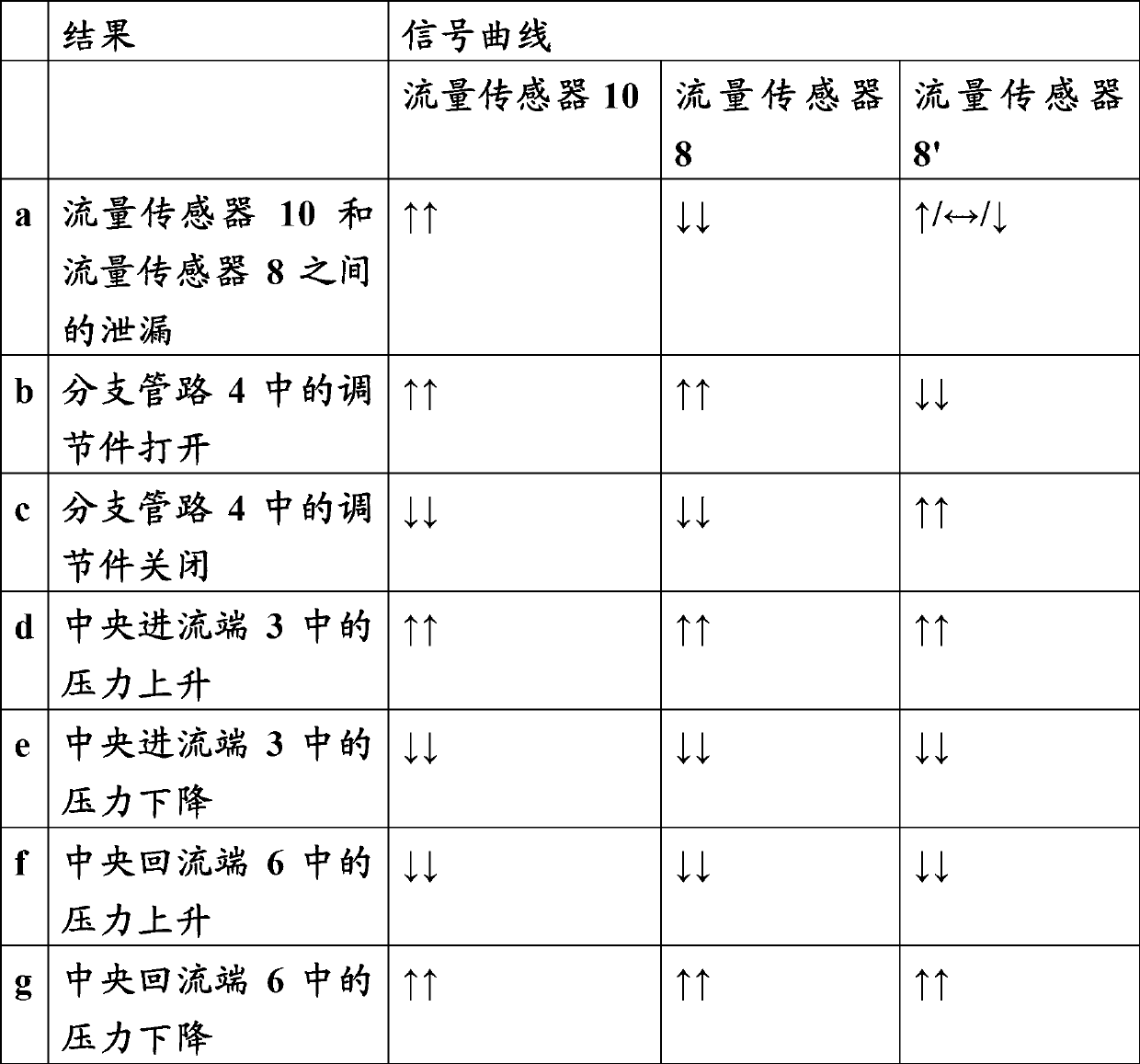

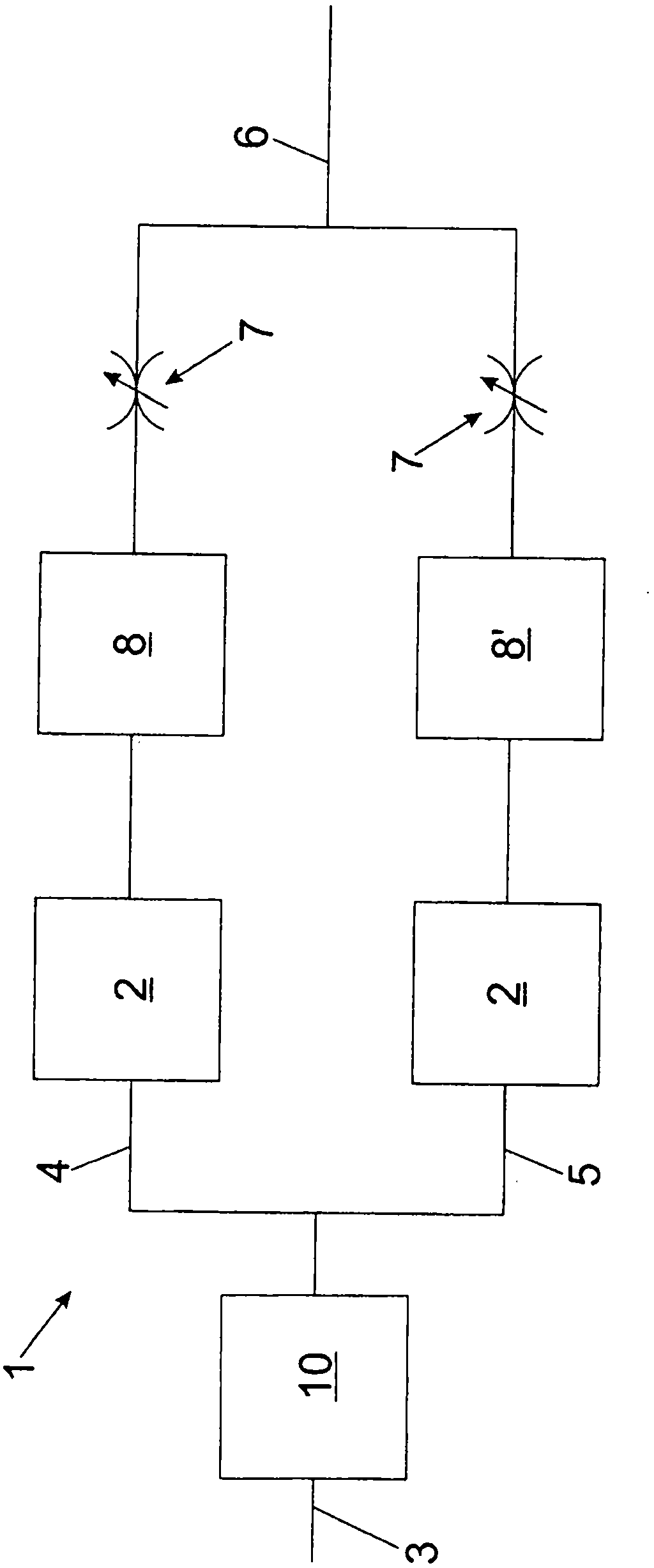

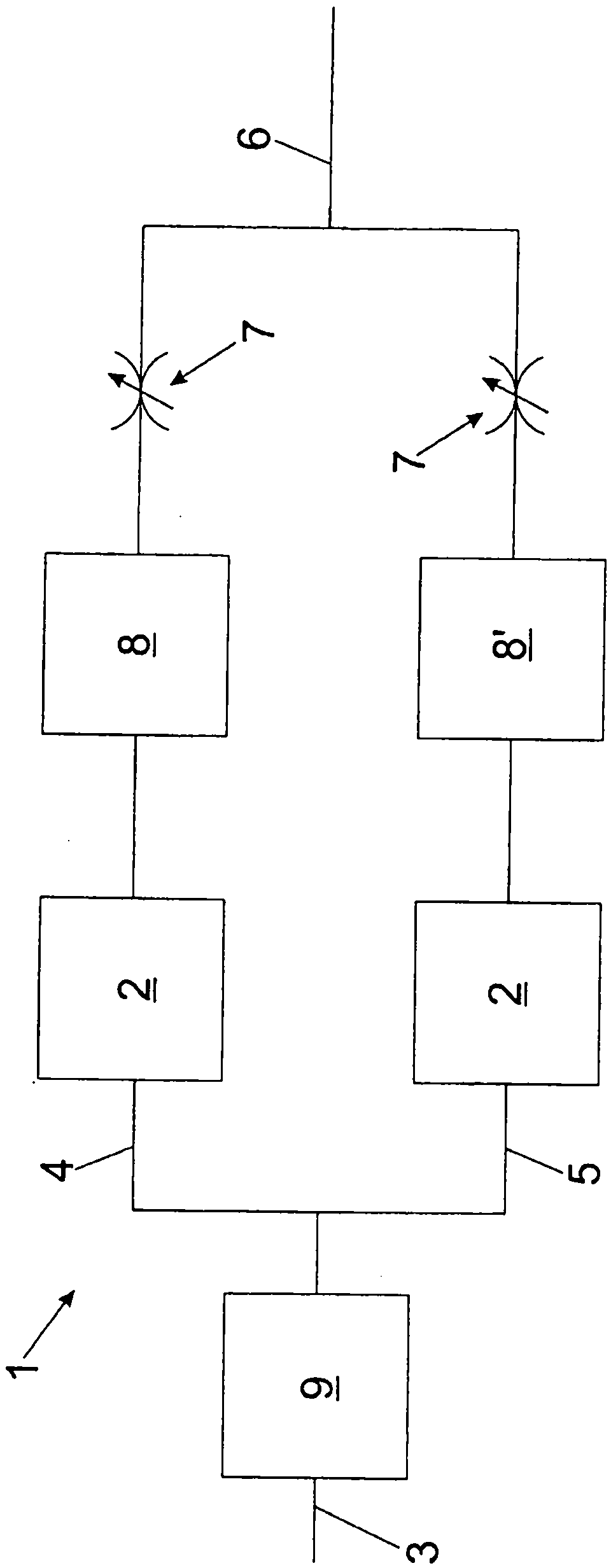

The invention relates to a method used for monitoring a temperature control device of dies of an injection molding machine or a die-casting machine. The temperature control device (1) comprises an inflow end (3) and a backflow end (6), and at least two branch pipelines (4,5) which are connected in parallel with the inflow end and the backflow end on a flowing technology. Each of the at least two branch pipelines (4,5) is provided with a flow sensor (8,8'). Through comparing measuring data provided by the flow sensor (8,8'), pressure surge in the inflow end (3) and the backflow end (6) are separated from existence of leakage.

Description

technical field The invention relates to a method for monitoring a temperature-regulating device of a mold of an injection molding machine or a die-casting machine, the temperature-regulating device comprising an inflow end and a return flow end, at least two branch lines being arranged in flow-technical parallel connection at the inflow end A flow sensor is arranged in each of the at least two branch lines between the flow end and the return end. Background technique Molds for plastics processing are usually provided with a channel system which has at least one inflow end, one return end and branch lines (channel loops) arranged in between. This channel system allows fluid to enter the areas within the mold where energy is to be supplied or conducted away. In many plastics processing methods – and thus also in injection molding – it is important to be able to influence the temperature in individual areas of the mold in a targeted manner, so that the entire channel system ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M3/28

CPCB29C45/7306B29C45/768B29C2945/76006B29C2945/76056B29C2945/76304B29C2945/76494G01M3/26

Inventor F·拉施克

Owner ENGEL AUSTRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com