Vehicle moving system and laying method thereof

A vehicle movement and vehicle technology, applied in the field of vehicle movement systems, can solve problems such as long construction period and complex construction, and achieve the effects of shortening construction time, saving construction costs, and omitting costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

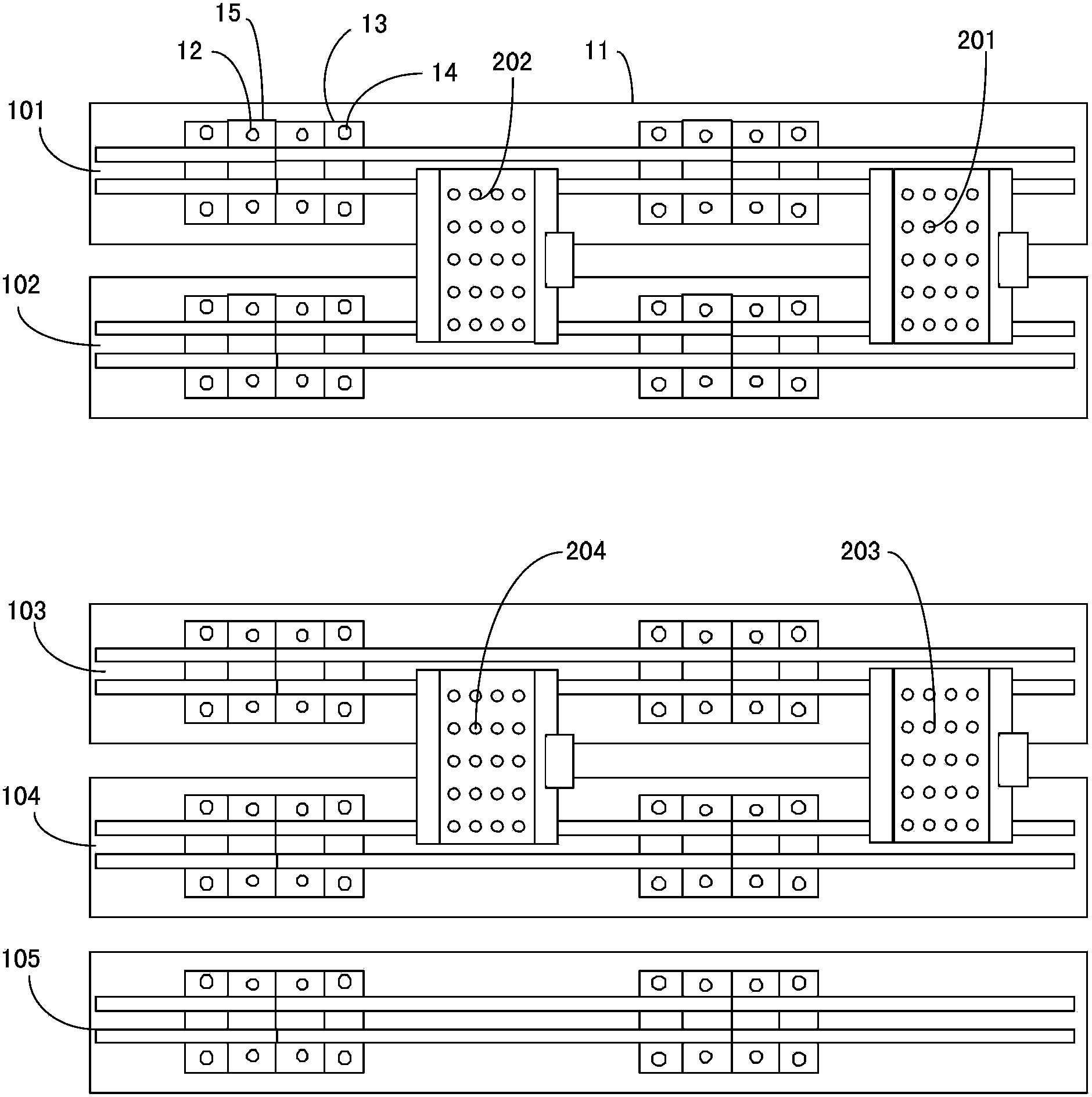

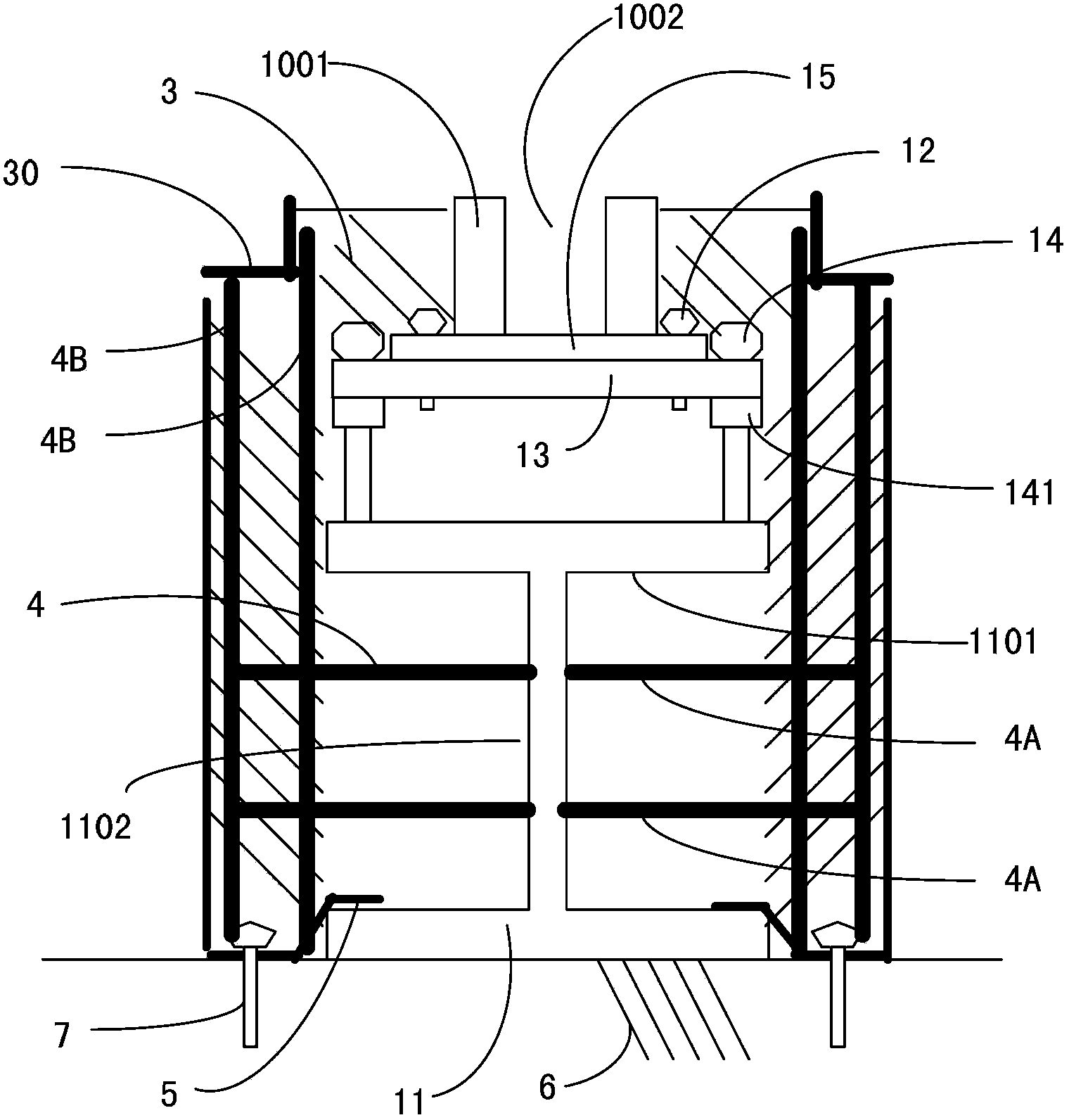

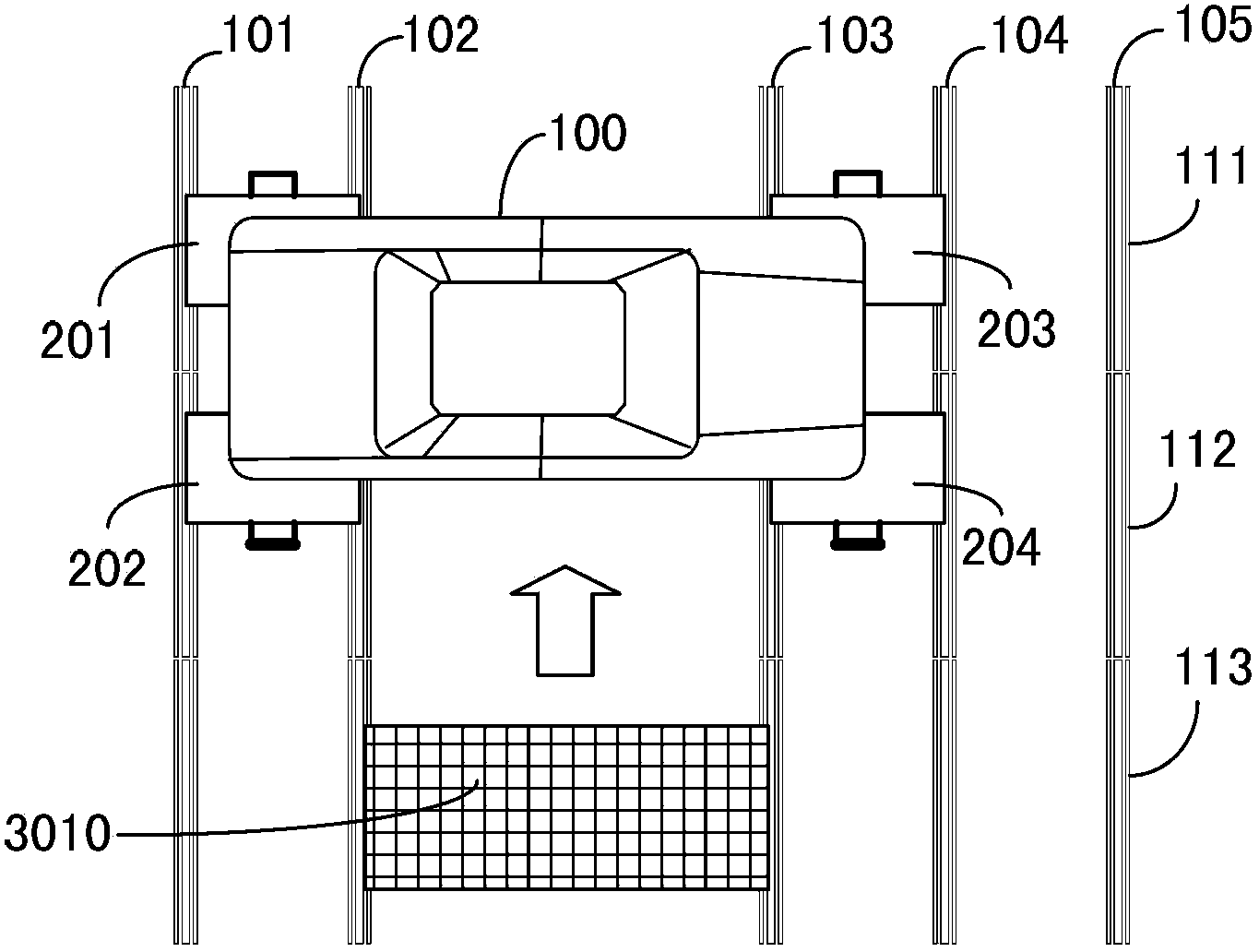

[0034] Figure 1-Figure 5 The structure of the preferred embodiment 1 of the vehicle moving system of the present invention is shown from different angles. In order to illustrate the structure and laying method of the preferred embodiment 1 more clearly, the structure and laying method will be described simultaneously below.

[0035] exist Figure 1-Figure 5 In the first preferred embodiment shown, guide rails 101 , 102 , 103 , 104 , 105 and vehicle trays 201 , 202 , 203 , 204 are provided altogether. Wherein, the vehicle trays 201-204 are respectively used to carry the four wheels of the vehicle 100, when the vehicle 100 moves from one end of the guide rails 101-104 to the other end along the direction of the arrow (such as image 3 ), the vehicle 100 has been repaired by multiple maintenance technicians at multiple stations, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com