Waterborne acrylic acid modified alkyd resin and preparation method

A water-based acrylic and alkyd resin technology, used in coatings, polyester coatings, etc., can solve problems such as high toxicity, liver and kidney damage, animal reproductive system damage, etc., and achieve the effect of uniform molecular weight and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

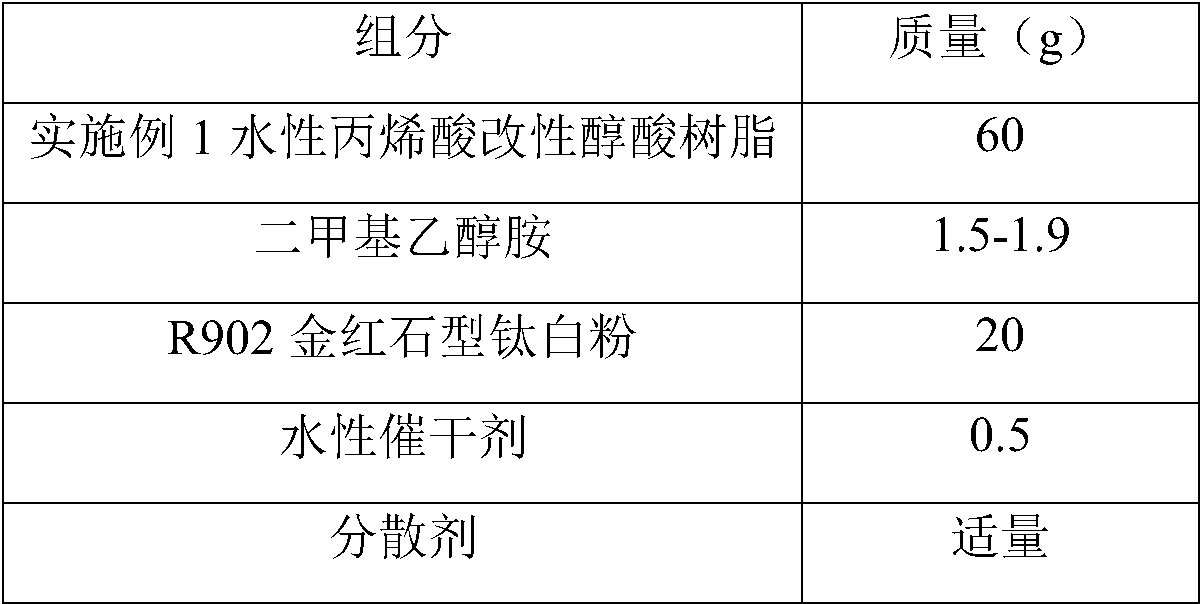

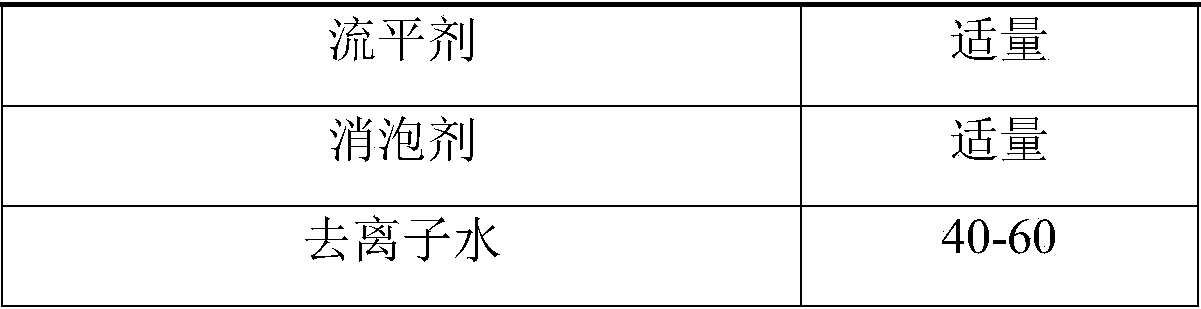

Examples

Embodiment 1

[0030] 1, a kind of water-based acrylic acid modified alkyd resin, it is made by the raw material of following percentage by weight: 22% soybean oil fatty acid, 14% trimethylolpropane, 13% phthalic anhydride, 0.05% hypophosphorous acid, 1% reflux xylene, 0.7% maleic anhydride, 2.5% trimellitic anhydride, 4% methyl methacrylate, 6% styrene, 1% butyl acrylate, 0.5% initiator dibenzoyl peroxide, 28% propylene glycol methyl ether.

[0031] 2, the preparation method of waterborne acrylic acid modified alkyd resin, comprises the following steps:

[0032] (1) 22% soybean oil fatty acid, 14% trimethylolpropane, 13% phthalic anhydride, 0.05% hypophosphorous acid, 1% reflux xylene are dropped in the reaction kettle by weight percentage, then be warming up to 180 ℃ of insulation 3 hours, use 2 Heat up from 180°C to 220°C within hours, and then reflux at 220°C-230°C for esterification. After reflux for 2 hours, start sampling to measure the acid value. Take it out and take a sample to me...

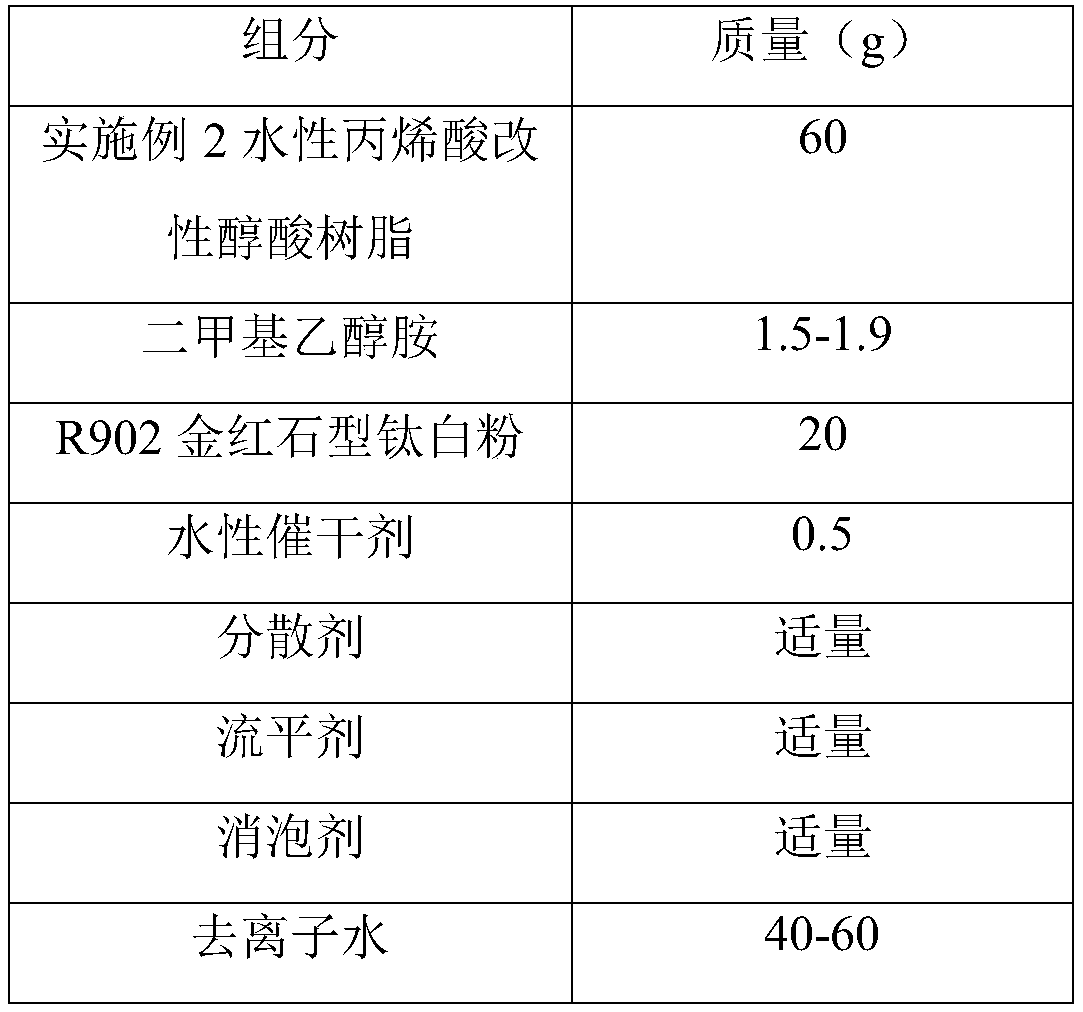

Embodiment 2

[0044] 1, a kind of water-based acrylic acid modified alkyd resin, it is made of the raw material of following percentage by weight: 12% sunflower oil acid, 12% linseed oil fatty acid, 15% trimethylolethane, 14% phthalic anhydride, 0.15% linoleic acid Triphenyl phosphate, 3% refluxed xylene, 1% maleic anhydride, 2.7% trimellitic anhydride, 5% methyl methacrylate, 8% styrene, 2% butyl acrylate, 1% initiator azobisiso Nitrile, 29% propylene glycol methyl ether.

[0045] 2, the preparation method of waterborne acrylic acid modified alkyd resin, comprises the following steps:

[0046] (1) 12% sunflower acid, 12% linseed oil fatty acid, 15% trimethylolethane / 14% phthalic anhydride, 0.15% triphenyl phosphite, 3% reflux xylene are dropped into the reactor by weight percentage, Then heat up to 180°C for 3 hours, then heat up from 180°C to 220°C in 2.5 hours, then reflux at 220°C-230°C for esterification, and start sampling to measure the acid value after reflux for 2 hours. When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com