Reaction container

A reaction vessel and accommodating space technology, which is applied in the field of application vessels, can solve the problems of poor stirring effect and low utilization rate of steam in the reaction vessel, and achieve the effects of improving the stirring effect, improving the utilization rate, and improving the stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

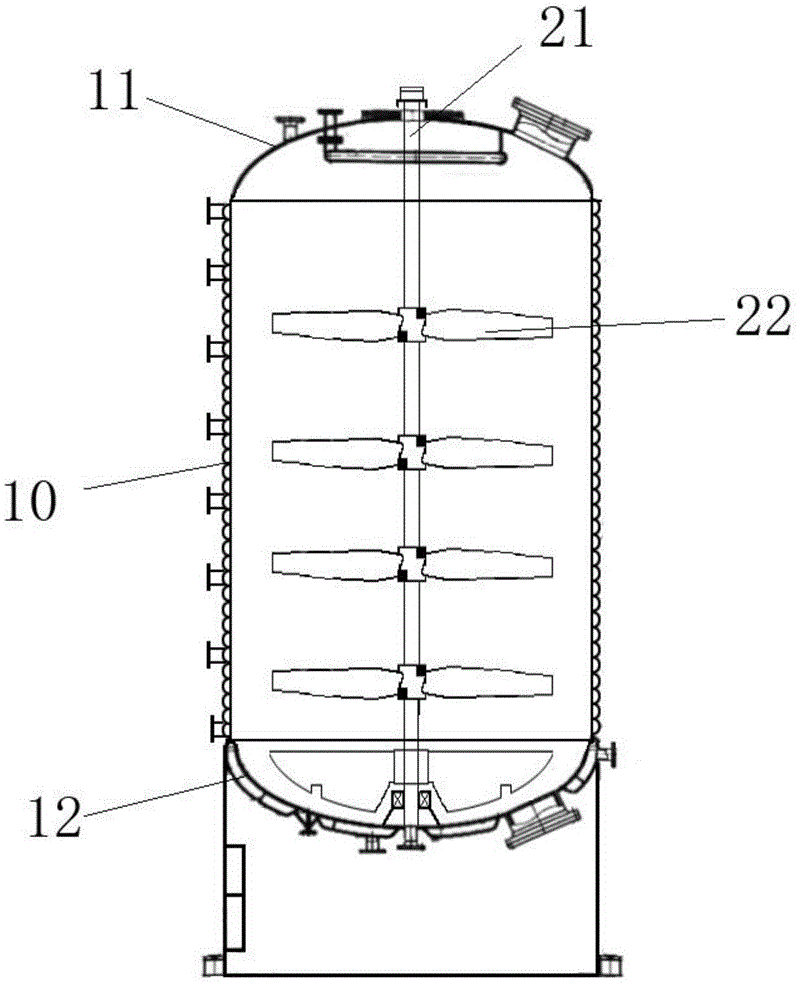

[0042] This embodiment provides a kind of reaction container, is adapted to as the reaction container that needs soft water as reaction raw material and needs to heat up, as figure 1 and 3 and 4, including,

[0043] The tank body 10 has an accommodation space;

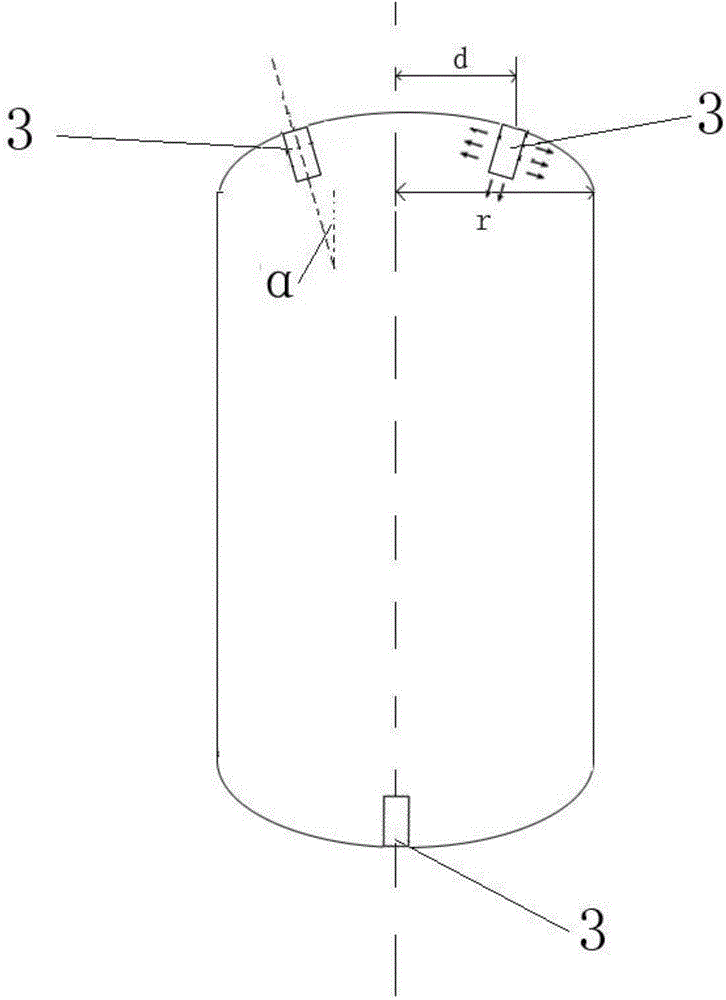

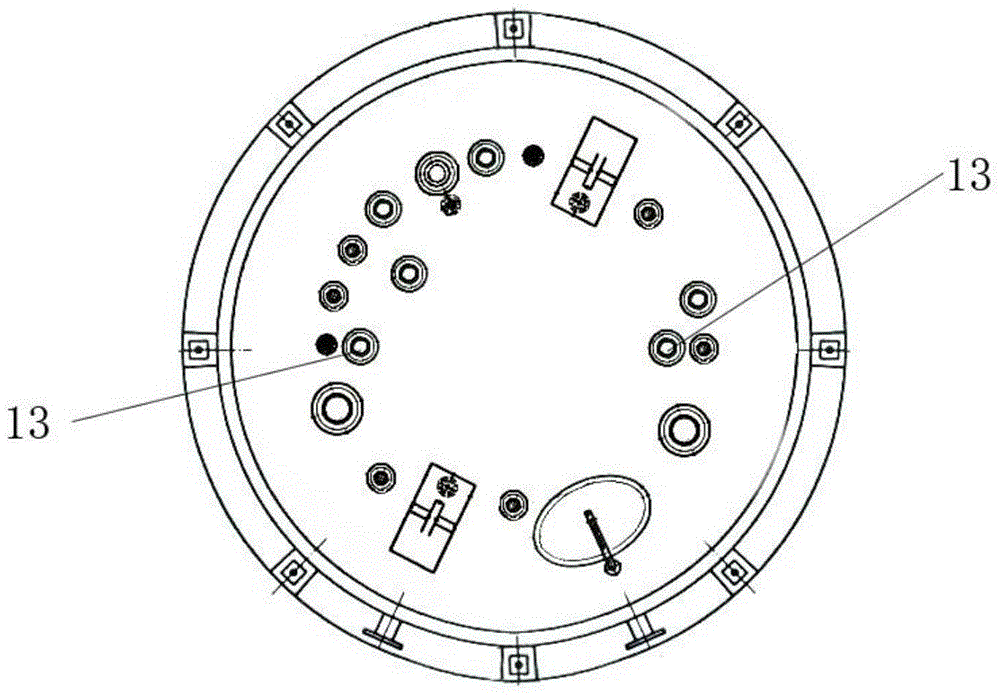

[0044] Steam inlets 13, preferably 4, 2 are arranged on the tank top 11 at the top of the tank body 10, and 2 are arranged on the tank bottom 12 at the bottom of the tank body 10, as figure 2 As shown, it is worth noting that, figure 2 The two steam inlets 13 on the bottom 12 of the middle tank overlap. In the top view of the tank body 10, the line connecting the two steam inlets 13 on the top 11 of the tank and the two steam inlets 13 on the bottom 12 of the tank perpendicular to each other;

[0045] The steam dispersing element 3 is located in the accommodating space, and is used to introduce the steam from the steam inlet 13 into the accommodating space, having

[0046] The inner cylinder 31 forms a steam intro...

Embodiment 2

[0069] This embodiment provides a reaction vessel, which is a modification based on Example 1. The difference between this embodiment and Example 1 is that the reaction vessel of this embodiment,

[0070] The sum of the areas of all the second through holes 323 is S1, the sum of the areas of all the first through holes 313 is S2, the cross-sectional area of the opening is S3, and S1, S2, and S3 conform to the following proportional relationship:

[0071] S1:S2:S3=8:1:4.

[0072] The ratio of the diameter of the steam introduction chamber 4 to the diameter of the steam buffer chamber is R4:R5=1.8:1, the width of the gap is D, the length of the steam buffer chamber is L, and D and L satisfy the following proportional relationship D:L=1:7.

[0073] The diameter of the second through hole 323 is R1, the diameter of the first through hole 313 is R2, the diameter of the opening 41 is R3, R1, R2, R3 satisfy the following proportional relationship: R1: R2: R3 =1:4:5.

[0074] The...

Embodiment 3

[0078] This embodiment provides a reaction container, which is a modification based on embodiment 1 or 2. The difference between this embodiment and embodiment 1 is that the reaction container of this embodiment,

[0079] The sum of the areas of all the second through holes 323 is S1, the sum of the areas of all the first through holes 313 is S2, the cross-sectional area of the opening is S3, and S1, S2, and S3 conform to the following proportional relationship:

[0080] S1:S2:S3=10:1:5.

[0081] The ratio of the diameter of the steam introduction chamber 4 to the diameter of the steam buffer chamber 5 is R4:R5=2:1, the width of the gap is D, the length of the steam buffer chamber 4 is L, and D and L satisfy the following Proportional relationship D:L=1:8.

[0082] The diameter of the second through hole 323 is R1, the diameter of the first through hole 313 is R2, the diameter of the opening 41 is R3, R1, R2, R3 satisfy the following proportional relationship: R1: R2: R3 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com