Preparation and application of graphene/substrate electrode and polyaniline-graphene/substrate electrode

A base electrode and graphene technology, applied in the field of electrodes, to achieve the effects of facilitating the formation of biofilms, improving power output, and huge attachment area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

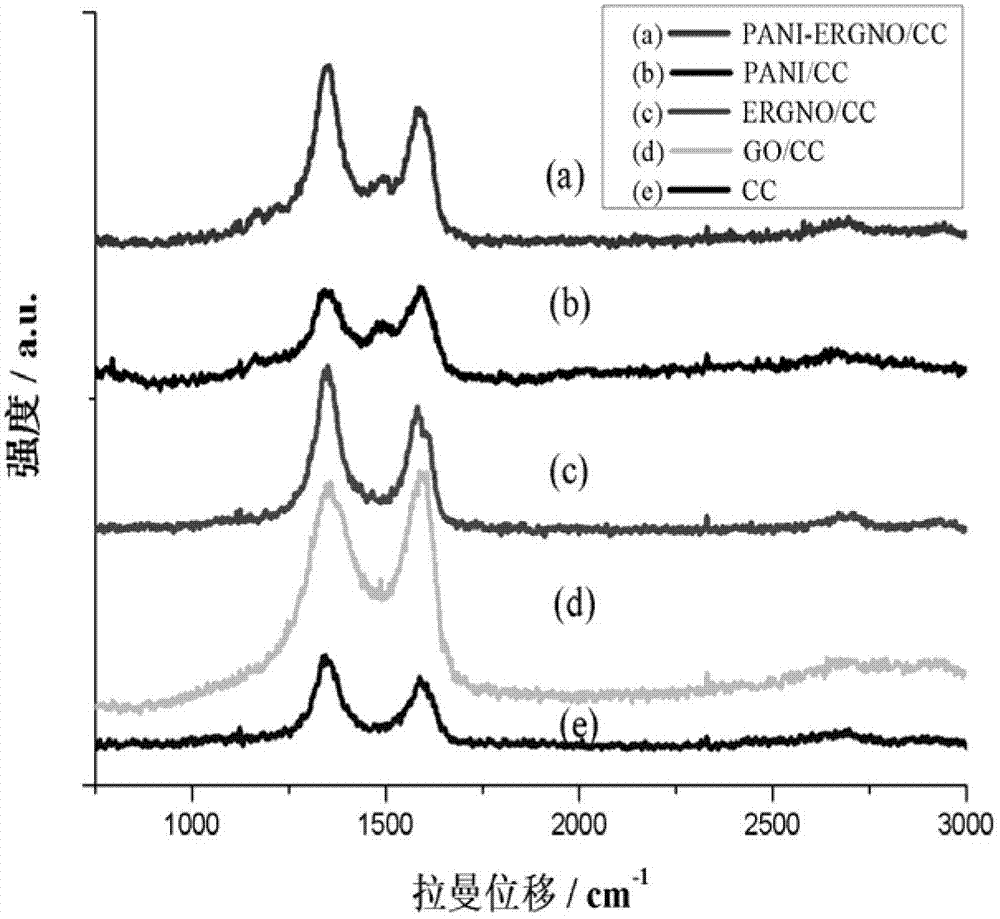

Embodiment 1

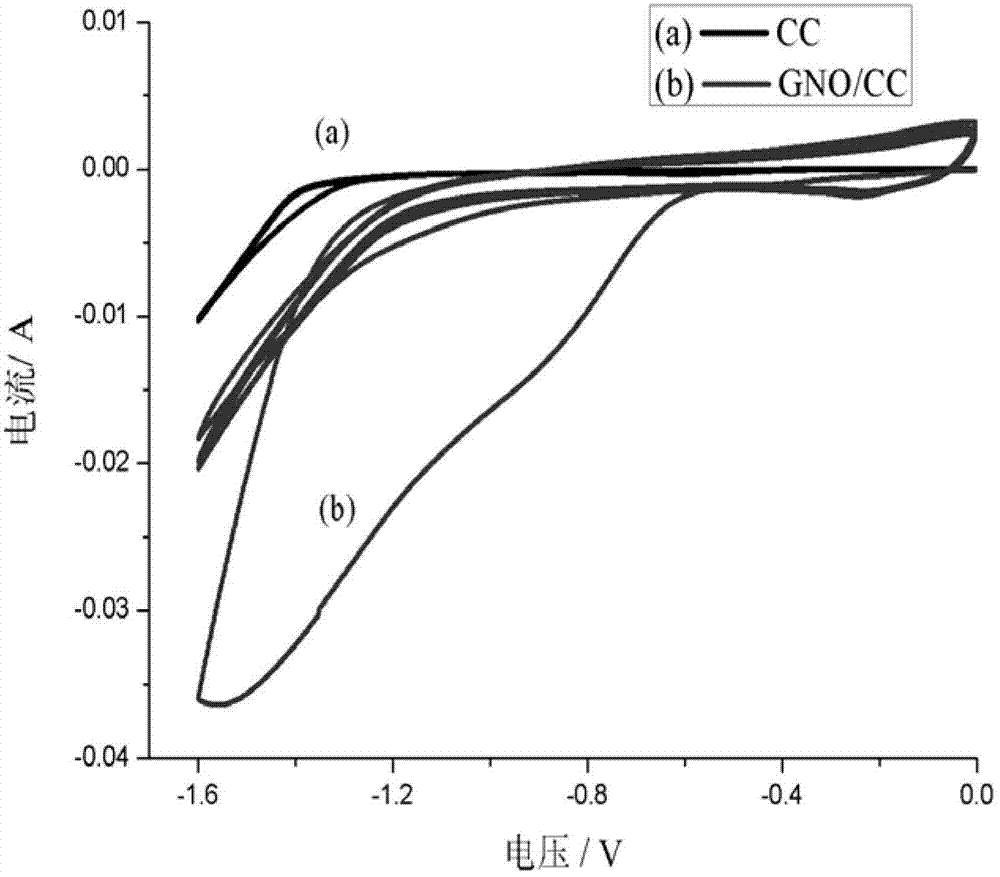

[0044] This example is used to illustrate the process of obtaining graphene / substrate electrode by electrochemical reduction method from graphene oxide / substrate electrode.

[0045] Utilize the method for preparing graphene / substrate electrode by electrochemical reduction method, it is characterized in that, comprises the following steps:

[0046] (1) The graphene oxide aqueous solution is ultrasonically obtained to obtain a uniform and stable dispersed graphene oxide aqueous solution;

[0047] (2) Evenly drop-coat the above-mentioned graphene aqueous solution onto the base electrode, and dry naturally to obtain graphene oxide / base electrode;

[0048] (3) Using a three-electrode system, the graphene / substrate electrode was reduced by cyclic voltammetry to obtain a graphene / substrate electrode; it was dried naturally.

[0049] A carbon cloth with a size of 1.8 cm×1.8 cm is used as a base electrode, and the amount of graphene oxide attached to the base electrode is 2 mg for exa...

Embodiment 2

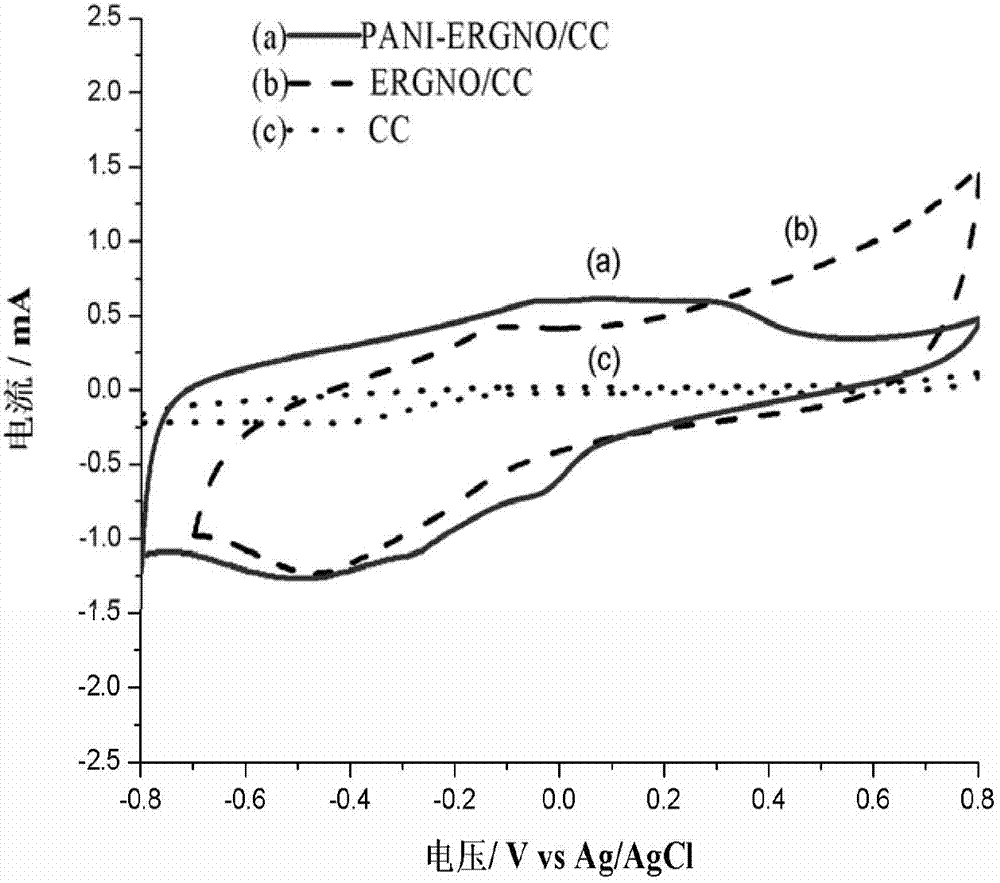

[0051] The preparation method of polyaniline-graphene / substrate electrode, comprises the following steps:

[0052] (1) Dissolve 0.3g of aniline in 10mL of 1mol / L hydrochloric acid, quickly add it to the prepared solution of 10mL of 1mol / L hydrochloric acid containing 0.18g of ammonium persulfate, stir overnight, and obtain the polyaniline solution;

[0053] (2) Filter the solution in the above step (1), wash with deionized water until the filtrate is neutral; dry in a vacuum oven at 60°C to obtain polyaniline powder;

[0054] (3) Dissolve the dried polyaniline solution in water, and ultrasonically obtain a stable dispersed polyaniline aqueous solution; the concentration is preferably 1 mg / mL;

[0055] (4) Soak the graphene / substrate electrode prepared in Example 1 in a uniformly dispersed polyaniline aqueous solution, take it out and dry it naturally to obtain a graphene-polyaniline / substrate electrode.

Embodiment 3

[0057] This example is used to illustrate the assembly of microbial fuel cells using the electrodes prepared in Example 1 and Example 2.

[0058] The microbial fuel cell adopts a double-chamber structure, which is composed of two circular plexiglass, and the volume of the anode and cathode chambers is 40mL. The cathode and anode chambers are separated by a nafion117 proton exchange membrane with a size of 2cm×2cm. Anolyte consists of 1g / L CH 3 COONa,0.3g / L NH 4 Cl, 1g / L Nacl, 0.03g / LMgSO 4 ,0.04g / L CaCl 2 ,0.2g / L NaHCO 3 ,5.3g / L K 2 HPO 4 ,10.7g / L KH 2 PO 4 The catholyte consists of 32.9g / L potassium ferricyanide and pH=6.9 buffer solution (5.3g / L K 2 HPO 4 ,10.7g / L KH 2 PO 4 ) is configured, and a carbon felt with a thickness of 3mm and a size of 2cm×2cm is used as the cathode. The MFC is placed in a constant temperature bath at 35°C and operated under the condition of an external 500Ω external resistance. When the output voltage is less than 50mV, the anolyte an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com