SOFC composite cathode material containing abnormal thermal expansion behavior material as well as preparation method and application of SOFC composite cathode material

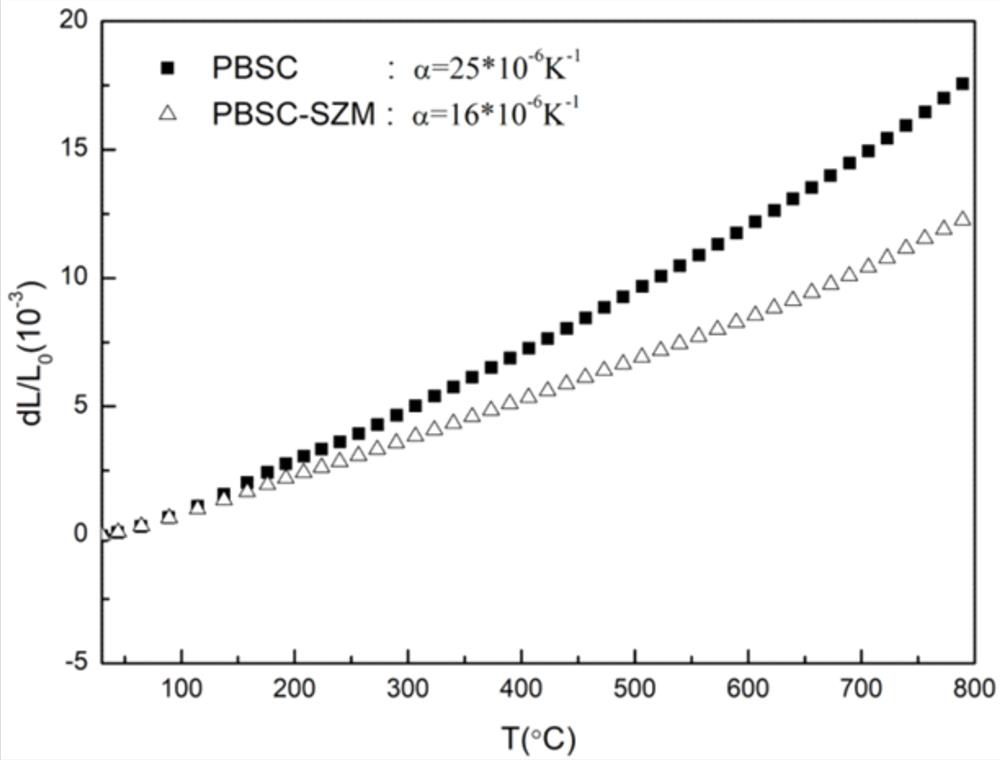

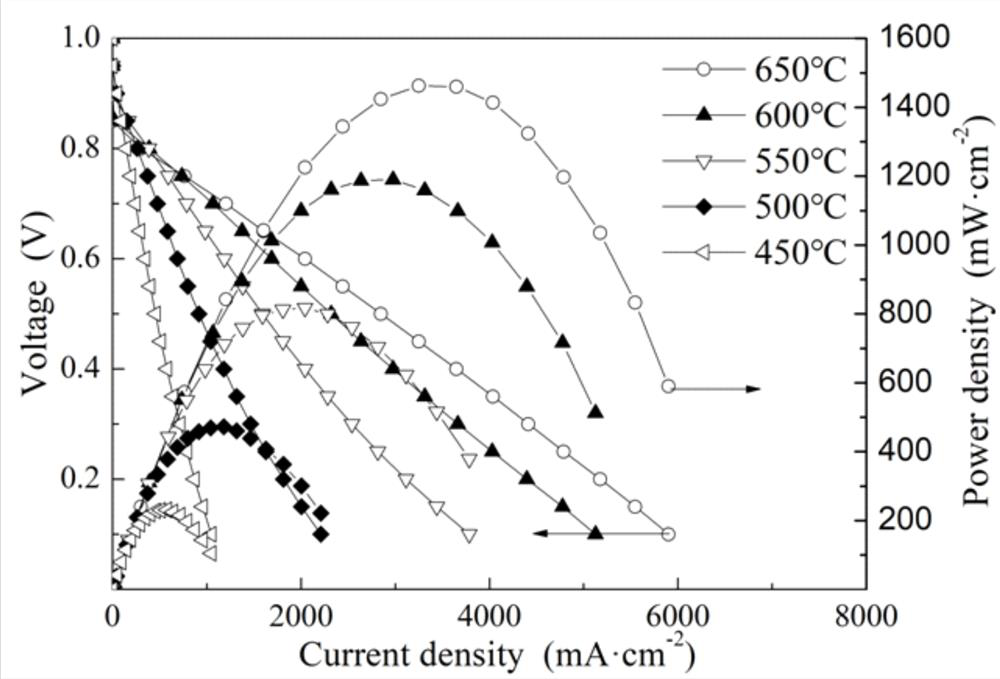

A composite cathode, thermal expansion technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of TEC control that cannot be cathode, reduce cathode, etc., achieve low polarization resistance, good thermal matching, good long-term stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

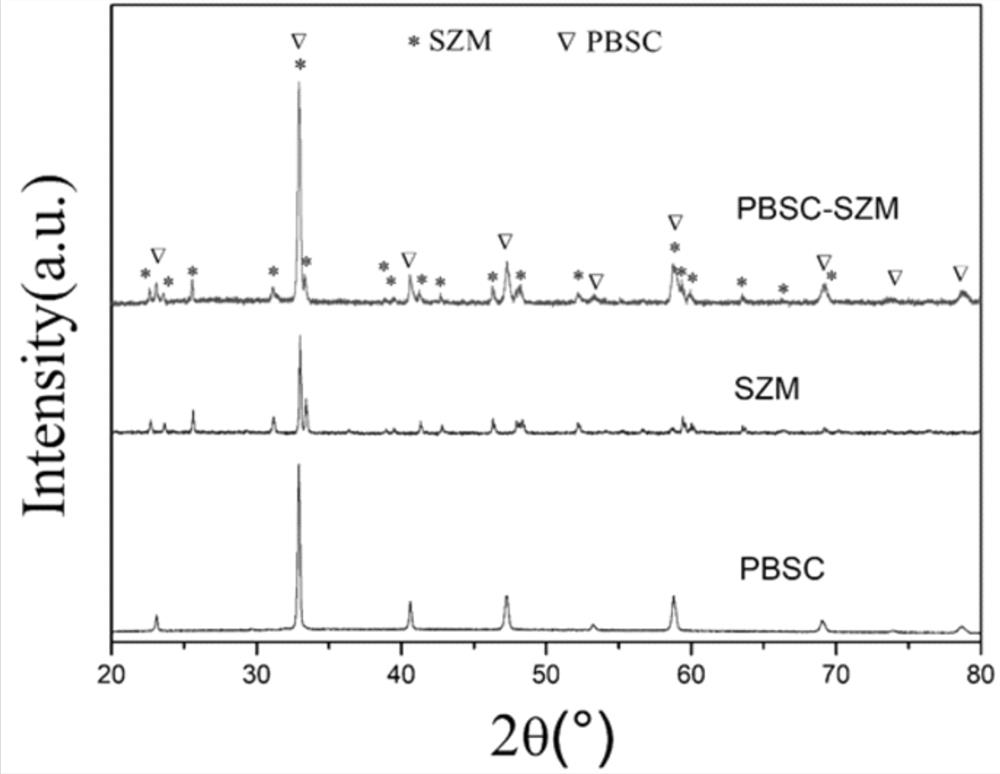

[0031] A SOFC composite cathode material containing a material with abnormal thermal expansion behavior, the component including PrBa 0.5 Sr 0.5 co 2 o 5+δ 、Sm 0.85 Zn 0.15 MnO 3 Complex.

[0032] PrBa 0.5 Sr 0.5 co 2 o 5+δ The mass percentage wt 1 80%, Sm 0.85 Zn 0.15 MnO 3 The mass percentage wt 2 20%. Recorded as 0.8PBSC-0.2SZM.

[0033] A method for preparing a SOFC composite cathode material containing a material with abnormal thermal expansion behavior, comprising the steps of:

[0034] a. Preparation of Sm 0.85 Zn 0.15 MnO 3 Powder: according to the stoichiometric ratio (ie Sm 3+ , Zn 2+ , Mn 3+ The molar ratio is 0.85:0.15:1) Weigh the corresponding Sm with a purity of more than 99.9wt%. 2 o 3 , ZnO with a purity of 99%wt or more, Mn with a purity of 99%wt or more 2 o 3 ; will Sm 2 o 3 , ZnO, Mn 2 o 3 Grind for 1 hour, then add absolute ethanol to grind for 1 hour, then dry to remove absolute ethanol, then use a powder tablet press to pres...

Embodiment 2

[0048] A SOFC composite cathode material containing a material with abnormal thermal expansion behavior, the component including PrBa 0.5 Sr 0.5 co 2 o 5+δ 、Sm 0.85 Zn 0.15 MnO 3 Complex.

[0049] PrBa 0.5 Sr 0.5 co 2 o 5+δ The mass percentage wt 1 90%, Sm 0.85 Zn 0.15 MnO 3 The mass percentage wt 2 10%. Recorded as 0.9PBSC-0.1SZM.

[0050] A method for preparing a SOFC composite cathode material containing a material with abnormal thermal expansion behavior, comprising the steps of:

[0051] a. Preparation of Sm 0.85 Zn 0.15 MnO 3 Powder: according to the stoichiometric ratio (ie Sm 3+ , Zn 2+ , Mn 3+ The molar ratio is 0.85:0.15:1) Weigh the corresponding Sm with a purity of more than 99.9wt%. 2 o 3 , ZnO with a purity of 99%wt or more, Mn with a purity of 99%wt or more 2 o 3 ; will Sm 2 o 3 , ZnO, Mn 2 o 3 Grind for 2 hours, then add absolute ethanol to grind for 2 hours, then dry to remove absolute ethanol, and then use a powder tablet machine...

Embodiment 3

[0060] A SOFC composite cathode material containing a material with abnormal thermal expansion behavior, the component including PrBa 0.5 Sr 0.5 co 2 o 5+δ 、Sm 0.85 Zn 0.15 MnO 3 Complex.

[0061] PrBa 0.5 Sr 0.5 co 2 o 5+δ The mass percentage wt 1 70%, Sm 0.85 Zn 0.15 MnO 3 The mass percentage wt 230%. Recorded as 0.7PBSC-0.3SZM.

[0062] A method for preparing a SOFC composite cathode material containing a material with abnormal thermal expansion behavior, comprising the steps of:

[0063] a. Preparation of Sm 0.85 Zn 0.15 MnO 3 Powder: according to the stoichiometric ratio (ie Sm 3+ , Zn 2+ , Mn 3+ The molar ratio is 0.85:0.15:1) Weigh the corresponding Sm with a purity of more than 99.9wt%. 2 o 3 , ZnO with a purity of 99%wt or more, Mn with a purity of 99%wt or more 2 o 3 ; will Sm 2 o 3 , ZnO, Mn 2 o 3 Grind for 1 hour, then add absolute ethanol to grind for 2 hours, then dry to remove absolute ethanol, then use a powder tablet press to pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com