Preparation method of cylindrical mixed solid-liquid lithium ion battery

A lithium-ion battery, cylindrical technology, applied in the field of preparation of mixed solid-liquid lithium-ion batteries, can solve problems such as unsatisfactory ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

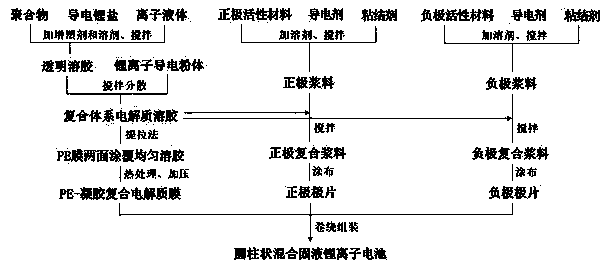

[0035] Such as figure 1 Shown, a kind of preparation method of cylindrical mixed solid-liquid lithium ion battery comprises the steps:

[0036] Step 1. Mix and stir the polymer, conductive lithium salt, ionic liquid, plasticizer, and solvent for dissolving the high molecular polymer and lithium salt to form a transparent sol, wherein the solvent does not interact with the high molecular polymer and lithium salt. For the reaction, mix and stir the transparent sol and lithium ion conductive powder (that is, fast lithium ion conductors such as oxides or sulfides) to form a uniform composite system electrolyte sol, and test its viscosity;

[0037] Step 2, mix the positive electrode active material, conductive agent, binder, and solvent for dissolving the high molecular polymer and lithium salt, and stir evenly to prepare positive electrode slurry, wherein the solvent does not interact with the high molecular polymer and lithium salt. Reaction, mix the composite system electrolyte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com