Dynamic high-capacity nickel-hydrogen battery and production process thereof

A nickel-metal hydride battery, high-capacity technology, applied in nickel batteries, secondary batteries, alkaline batteries, etc., can solve the problems of unfavorable charging and discharging, large internal resistance of batteries, and high current density, to increase the contact surface, reduce battery Internal resistance, to achieve the effect of charging or discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

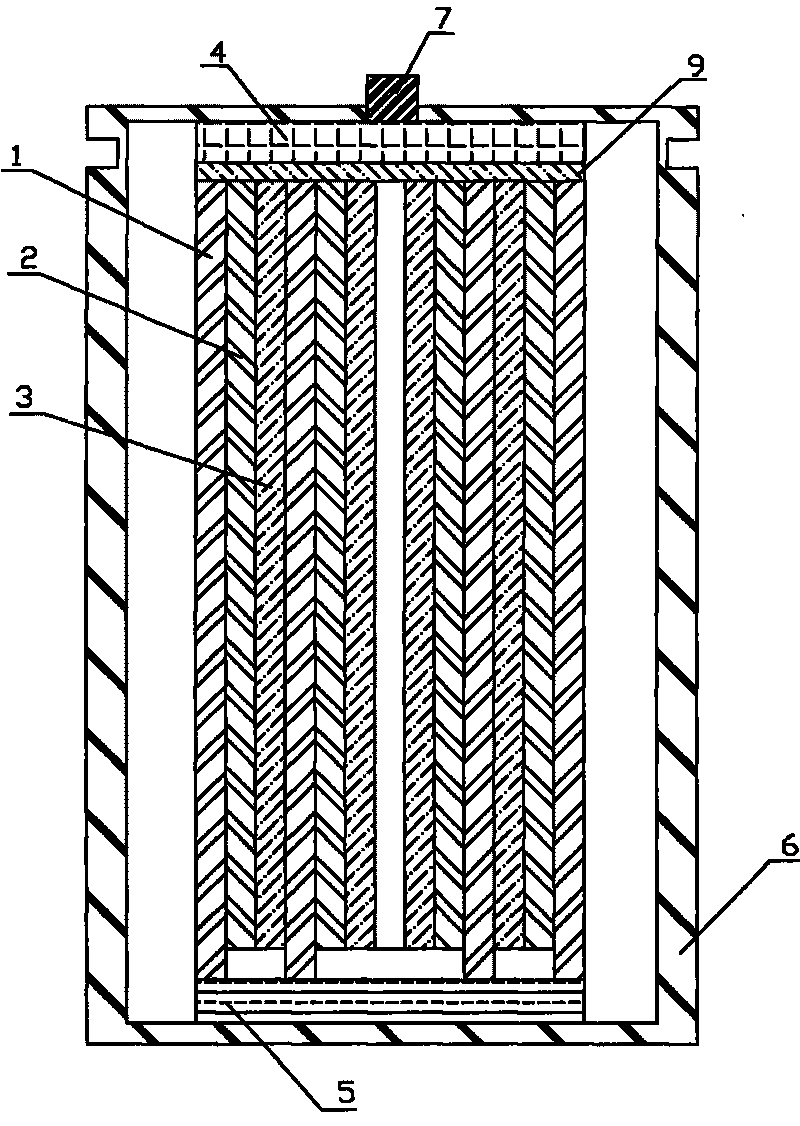

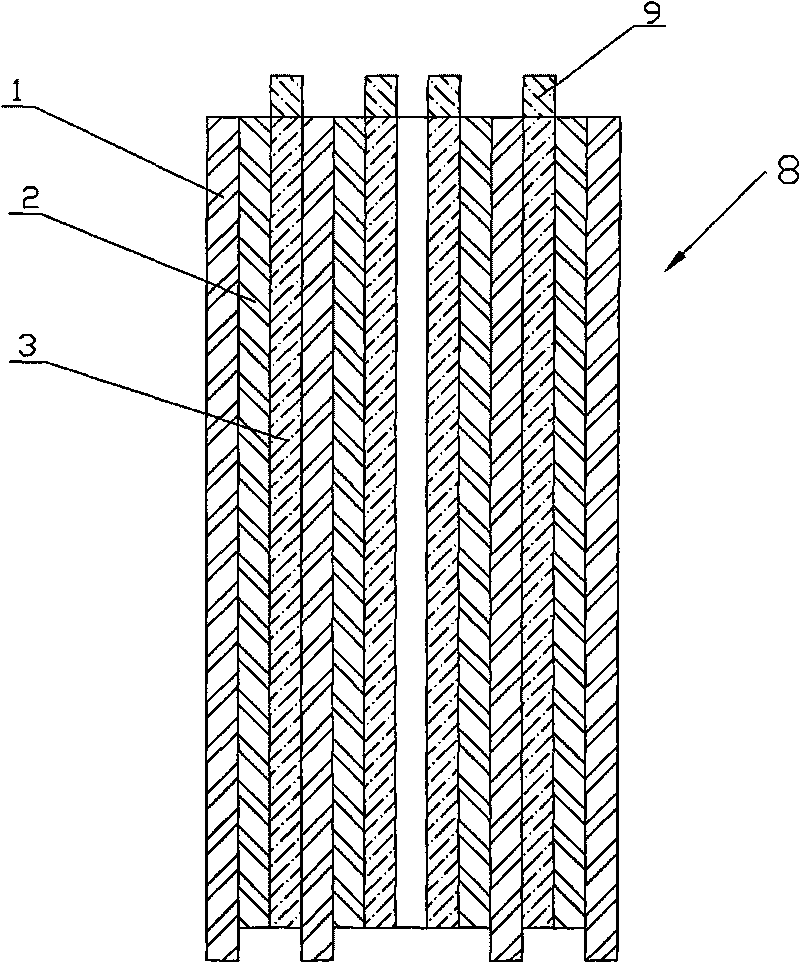

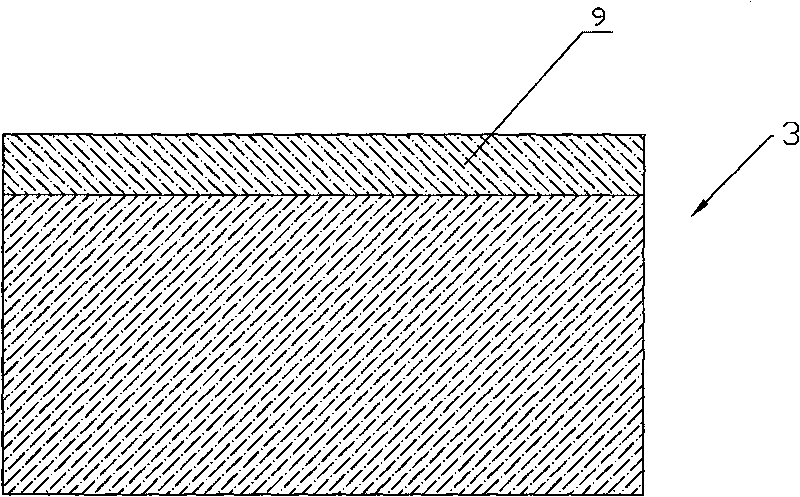

[0028] The making of a nickel electrode 3: Ni(II) hydroxide, catalyst, additive, conductive agent and PTFE with a concentration of 10% are mixed and filled into the foamed nickel containing 99.8% of nickel, and the part 6mm away from the top of the foamed nickel is not Filling material, the above-mentioned filling material and foamed nickel together form nickel electrode 3 and control the thickness of nickel electrode 3 to 0.42mm, and the foamed nickel part that is not filled with material is the reserved foamed nickel part 9;

[0029] The production of b hydrogen electrode 1: using copper mesh as a carrier, the hydrogen storage alloy powder is mechanically rolled on the copper mesh as an electrode sheet, and the thickness of the electrode sheet is controlled to be 0.22mm, and the electrode sheet is then soaked in a concentration of 5%. PTFE, which can effectively prevent the electrode sheet from being corroded by the electrolyte, and the above-mentioned electrode sheet soaked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com