Preparation method and application of a sludge carbon plate electrode

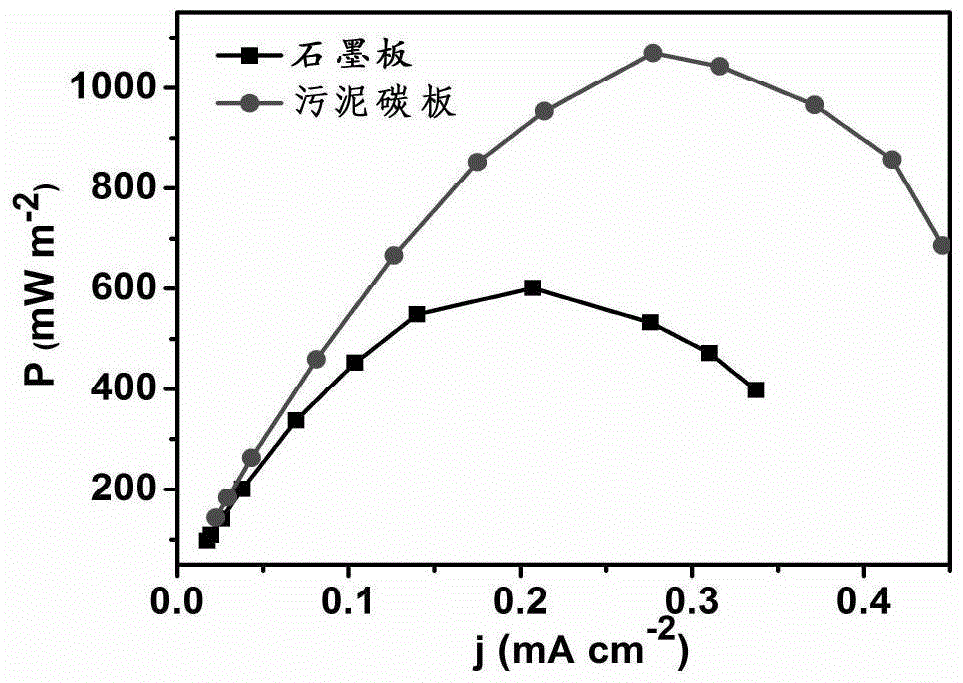

A plate electrode and sludge carbon technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as pollution, carbon emissions, and waste, and achieve the effects of simple and fast methods, increased power density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

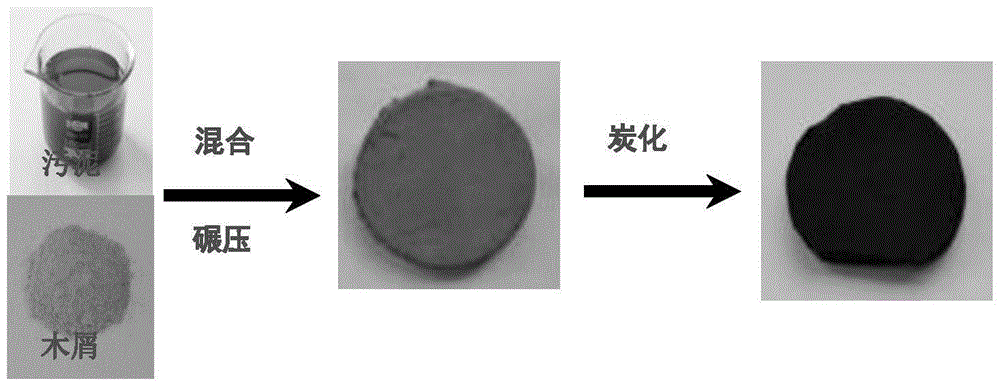

[0024] A preparation method of sludge carbon plate electrode, comprising the following steps:

[0025] 1) Crush the sawdust and sieve;

[0026] 2) Dry the sludge, crush and sieve to obtain dry sludge powder;

[0027] 3) Mix wood chips and sludge dry powder according to the weight ratio of (0~30):100, add water with a weight of 20%~65% of the total weight of wood chips and sludge dry powder, mix well, and roll into shape;

[0028] 5) Take out the mixture formed by rolling and forming in the previous step, dry it, and carbonize it under anaerobic conditions to obtain the electrode material, that is, the sludge carbon plate electrode.

[0029] Preferably, the wood chips in the above step 1) are sieved by 20-60 mesh sieves.

[0030] Preferably, the sieving of the sludge in the above step 2) is through a 60-120 mesh sieve.

[0031] Preferably, the drying described in the above step 2) is drying at 50-80°C until the moisture content is below 5%.

[0032] Preferably, the sawdust ...

Embodiment 1

[0039] A preparation method of sludge carbon plate electrode, comprising the following steps:

[0040] 1) Crush the sawdust and screen it with a 40-mesh sieve to obtain sawdust that meets the size requirements;

[0041] 2) Take the waste sludge from the sewage plant, dry it at 50-80 ℃ and grind it into powder, and sieve it with a 100-mesh sieve to get the sludge dry powder;

[0042] 3) Mix wood chips and sludge dry powder in proportions of 0:100, 5:100, 10:100, and 20:100, respectively, and pour the mixture into the mold, add water equal to 50% of the total weight of the two, and mix well , rolling forming;

[0043] 4) Take out the above-mentioned rolling-formed mixture, dry it at 50-80 °C until the moisture content is below 5%, and then put it into the cremation furnace for high-temperature gradient anaerobic carbonization, specifically at 400 °C, 500 °C, and 700 °C. ℃, 900℃, anaerobic carbonization for 30min in turn, to obtain the electrode material, that is, the sludge ca...

Embodiment 2

[0047] A preparation method of sludge carbon plate electrode, comprising the following steps:

[0048] 1) Crush the sawdust and screen it with a 20-mesh sieve to obtain sawdust that meets the size requirements;

[0049] 2) Take the discarded sludge from the sewage plant, dry it at 50-80 ℃ and grind it into powder, and sieve it with an 80-mesh sieve to get the sludge dry powder;

[0050] 3) Mix sawdust and sludge dry powder evenly in the ratio of 2:100, 4:100, 6:100, 8:100 respectively, mix and pour into the mold, add water with a weight of 65% of the total weight of the two, and mix well , rolling forming;

[0051] 4) Take out the above-mentioned rolling-formed mixture, dry it at 50-80 °C until the moisture content is below 5%, and then put it into the cremation furnace for high-temperature gradient anaerobic carbonization, specifically at 400 °C, 500 °C, 700 °C °C, 850 °C in the four temperature gradients, followed by anaerobic carbonization for 50 minutes, to obtain the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com