A Novel Proton Blocking Composite Cathode Material and Its Preparation Method and Application

A composite cathode and proton technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems that limit the practical application of Co-based perovskite cathode materials, poor thermal stability of cathode materials, matching of thermal expansion coefficients, etc., and achieve excellent electrical performance. Effects of comprehensive chemical properties, high power density, and low polarization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment is a novel proton blocking composite cathode material, the specific molecular formula is PrBa 0.5 Sr 0.5 Cu 2 O 5-δ -Ce 0.8 Sm 0.2 O 2-δ , x=0.3;

[0029] The specific preparation method of the above-mentioned proton blocking composite cathode material is as follows:

[0030] S1: put Pr 6 O 11 Dissolve in an appropriate amount of concentrated nitric acid to make a nitrate solution, and add Sr(NO) according to the stoichiometric ratio of metal ions while stirring. 3 ) 2 ·2H 2 O, Ba (NO 3 ) 2 , Cu(NO 3 ) 2 ·6H 2 O, to obtain a nitric acid solution containing mixed metal cations; according to the ratio of the total molar ratio of citric acid and metal cations to 1.5:1, add citric acid to the first acid solution containing mixed metal cations, add ammonia water to adjust pH to neutrality, and use A constant temperature heating magnetic stirrer was heated in a water bath at 80 °C, and the wet gel was obtained by complexation for 6 hours; the wet...

Embodiment 2

[0034] This embodiment is a novel proton blocking composite cathode material, and the specific molecular formula is:

[0035] PrBa 0.5 Sr 0.5 Cu 2 O 5-δ -Ce 0.8 Sm 0.2 O 2-δ , x=0.4; the specific preparation method of the proton blocking composite cathode material is the same as that in Example 1, the only difference is: in S3, the PBSC powder obtained by S1 and the SDC powder obtained by S2 are in a mass ratio of 6:4 The proportion of grinding and mixing.

Embodiment 3

[0037] A novel proton blocking composite cathode material of the present embodiment, the specific molecular formula is:

[0038] PrBa 0.5 Sr 0.5 Cu 2 O 5-δ -Ce 0.8 Sm 0.2 O 2-δ , x=0.5, the specific preparation method of the proton blocking composite cathode material is the same as that in Example 1, the only difference is: in S3, the PBSC powder obtained by S1 and the SDC powder obtained by S2 are in a mass ratio of 5:5 The proportion of grinding and mixing.

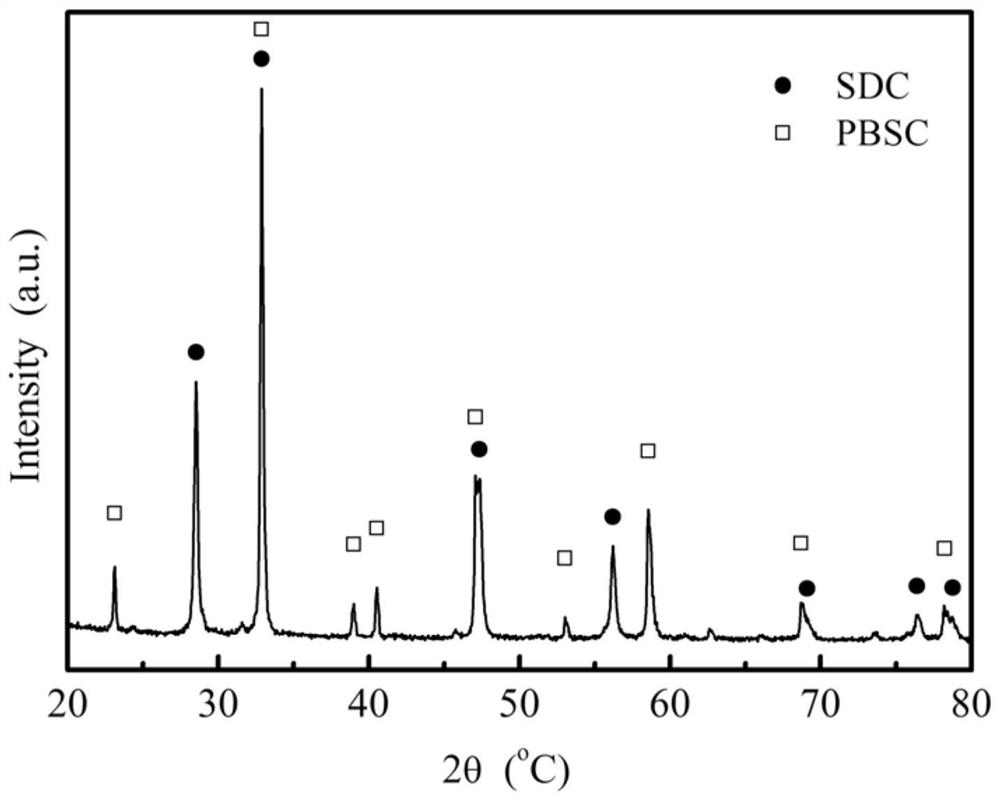

[0039] We tested the performance of the new proton blocking composite cathode material prepared in Example 1, figure 1 X-ray diffraction (XRD) of the cathode layer of the PBSC-SDC sample prepared in Example 1 after being treated at 1000° C. for 3h. It can be seen that after the treatment at 1000 °C, there is no obvious impurity peak, which is still the diffraction peak of PBSC and SDC. It shows that at 1000℃, PBSC and SDC still have good stability and no chemical reaction occurs.

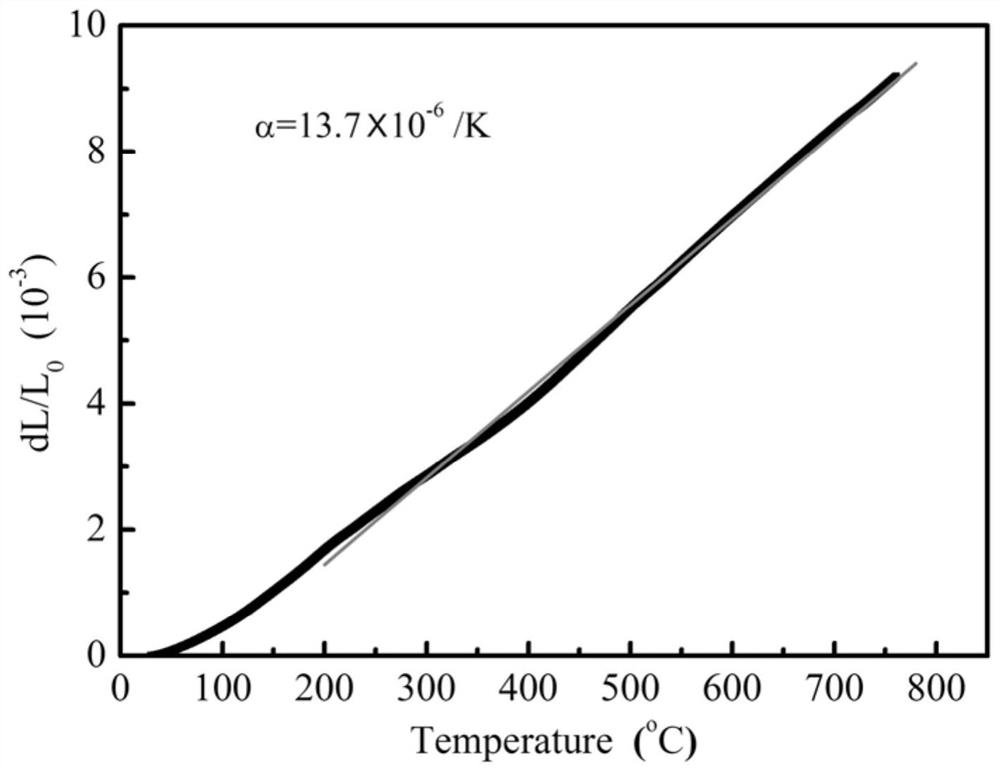

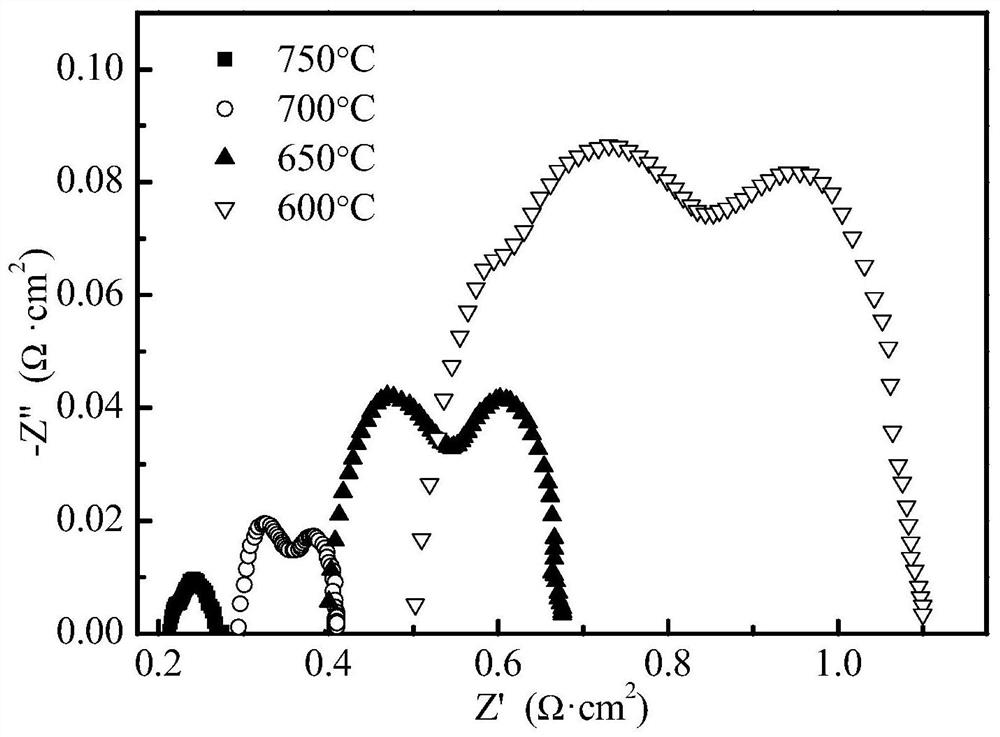

[0040] figure 2 is the the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com