Cobweb-based porous activated carbon fiber material and application

An activated carbon fiber and spider web technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems that spider silk cannot be fully utilized, the structure and performance characteristics of spider silk are not fully grasped, etc., and achieve stability and methanol resistance. The effect of improved performance, improved power density, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A porous active carbon fiber material includes the following steps:

[0030] 1) Collect indoor cleaning cobweb to remove impurities such as large particles solid and dust;

[0031] 2) Use exfoliating water, 1.0mol / L hydrochloric acid, hydrochloric acid, water -free ethanol ultrasound cleaning for 25min, and then wash it with ultra -pure water three times. Dry it at 60 ° C to less than 5%;

[0032] 3) Drying the dry cobweb under 250 ° C is 1H at low temperature pre -carbonization treatment, and then the high temperature carbonization treatment of 900 ° C is 1H, the porous active carbon fiber.

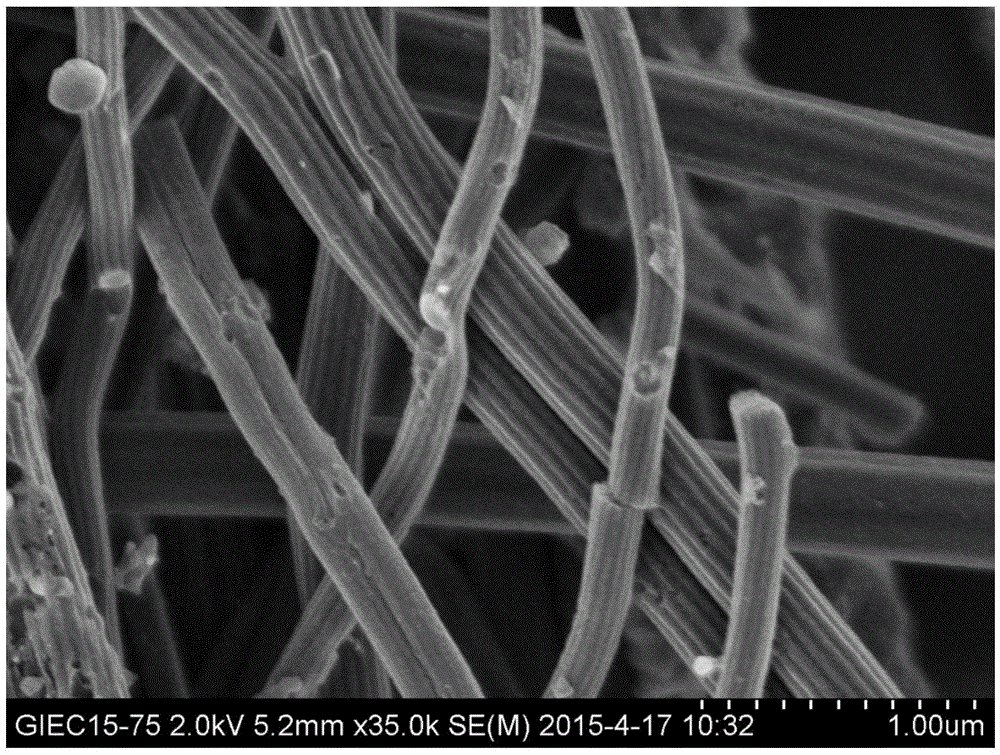

[0033] The porous active carbon fiber scanning electron microscope (SEM) prepared by this embodiment is figure 1 Show.The electron microscope shows that after the high temperature carbonization, the complete spider fiber structure is retained, and the diameter of the carbon fiber is about 100 to 200nm.

Embodiment 2

[0035] A porous active carbon fiber material includes the following steps:

[0036] 1) Collect indoor cleaning cobweb to remove impurities such as large particles solid and dust;

[0037] 2) Use exfoliating water, 2.0mol / L hydrochloric acid, hydrochloric acid, water -free ethanol ultrasound cleaning for 30 minutes, and then clean it with ultra -pure water three times. Dry it at 60 ° C to less than 5%;

[0038] 3) Treating the low -temperature pre -carbonization treatment of the dry cobweb at 250 ° C. After it naturally cools it to room temperature, it will be with a 3x quality FeCl 3 Or zncl 2 Mix, grind and mix well, and then use 900 ° C high -temperature carbonization to treat 2h porous active carbon fibers.

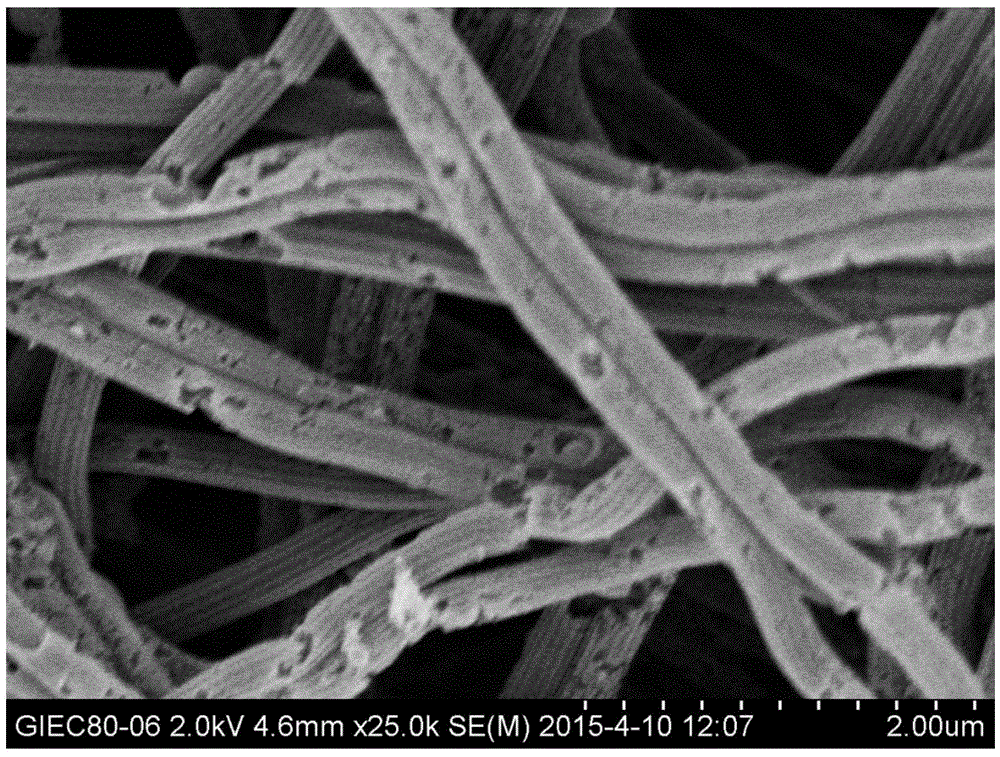

[0039] The porous active carbon fiber scan electron microscope prepared by this embodiment is figure 2 Show.The electron microscopy shows that high temperature activation treatment does not destroy the result of carbon fiber, but activated treatment has formed many micropo...

Embodiment 3

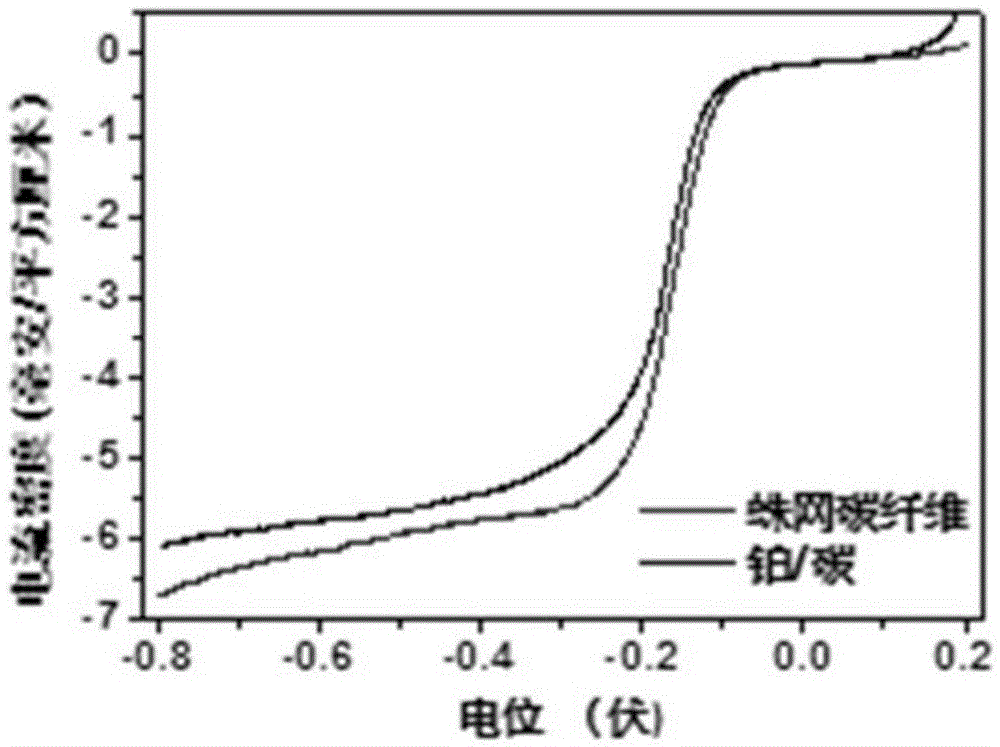

[0041] A microbial fuel cell catalytic reaction catalyst and its catalytic activity research, including the following steps:

[0042] 1) Use 1.0 μm, 0.5 μm, and 0.03 μm electrode polishing powder to treat the vita electrodes, and then clean it in ultrasound in water -free ethanol and ion water in sequence for 10 minutes, dry at 30 ° C;

[0043] 2) Reading 0.5 μg Examples 2 The carbonized cobweb powder obtained by prepared, add 50 μL of ionic water, 100 μl water -free ethanol, and 2 μlnafion solution to prepare a catalyst research solution;

[0044] 3) Take the 8 μL catalyst research solution and drip to the surface of the dry glass carbon electrode, dry it at 30 ° C, you can be used as a working electrode;

[0045] 4) Put the modified electrode in N 2 O 2 Electrochemical testing is performed in the 0.1mkoh solution, including cyclic voltty scanning, rotating disc electrode linear scanning, and studying prepared carbonized catalytic catalytic performance, stability, and methanolic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com