Preparation method and application of waste bacteria stick carbon anode

A technology of waste bacteria sticks and carbon anodes, which is applied in battery electrodes, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of occupying a large amount of land, environmental pollution, etc., achieves improved power density, simple preparation method, and is suitable for The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The waste bacteria rod carbon anode is prepared from the waste bacteria rod of seafood mushroom, and the specific steps are as follows:

[0025] (1) Dry the waste seafood mushroom sticks at 60 °C until the moisture content is ≤10%, and crush them to 60 mesh;

[0026] (2) Take 3g of the sieved waste seafood mushroom stick powder and place it in a stainless steel mold with an inner diameter of 3cm, and use a tablet machine to roll it into tablets at 10 and 20 MPa respectively;

[0027] (3) Place the pellets in a tube furnace for anaerobic high-temperature carbonization at 900 °C for 2 h to obtain the carbon anode of spent seafood mushroom sticks.

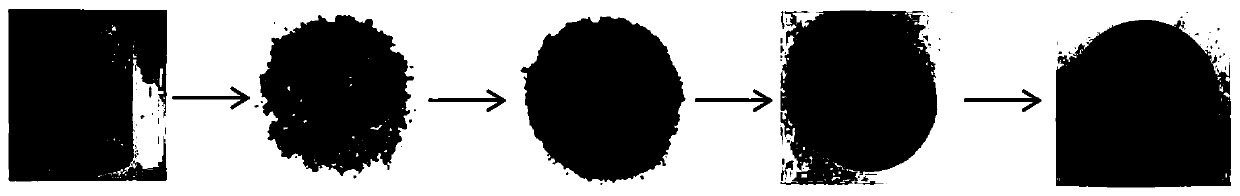

[0028] The preparation process of this embodiment is shown in figure 1 , the color of the fungus stick powder was loess color before the experiment, and the color turned black after the tablet was carbonized, and the tablets were well formed, and there was no fragmentation after carbonization.

[0029] The electron micrograph...

Embodiment 2

[0031] The waste fungus stick carbon anode was prepared from waste fungus sticks and coconut shells, and the specific steps were as follows:

[0032] (1) Dry the waste Tremella fungus sticks at 60 °C until the moisture content is below 10%, and crush them to 80 mesh;

[0033] (2) Cut the coconut shell into 5.0 cm × 1.5 cm × 0.5 cm, dry it at 60°C until the moisture content is below 10%, and crush it to an 80-mesh sieve;

[0034] (3) Mix the sifted white fungus waste fungus stick powder and coconut shell powder at a mass ratio of 0, 10%, and 20%, take 3g of the mixture and place it in a stainless steel mold with an inner diameter of 3cm, and use a tablet press at 20MPa Rolled down into pieces;

[0035] (4) Place the pellets in a tube furnace for anaerobic high-temperature carbonization at 800 °C for 3 h to obtain carbon anodes of three types of waste Tremella fungus sticks.

Embodiment 3

[0037] The application of different waste bacteria stick carbon anodes in microbial fuel cells is as follows:

[0038] (1) Construction of a single-chamber microbial fuel cell:

[0039] The battery chamber is a cuboid plexiglass measuring 6 cm × 6 cm × 4 cm, and a cylinder with a diameter of 3 cm and a height of 4 cm is hollowed out in the middle, and the internal effective volume is 28 mL.

[0040] The negative electrode is platinum-loaded carbon cloth, and its production process is as follows: first, the carbon cloth is subjected to 30% PTFE hydrophobization treatment, then one side is coated with a carbon base layer, and the other side is coated with 4 layers of PTFE air diffusion layer, and finally the diffusion layer The opposite side of the layer is coated with a platinum catalyst layer, the amount of platinum is 0.5 mg / m 2 , circular shape with an effective area of 7 cm 2 (diameter 3 cm), with air as the cathode electron acceptor.

[0041] The anodes were respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com