Method for processing gas film holes with continuous rows of integral special electrodes

An electrode processing and air film hole technology, which is applied in the field of engine blade processing equipment, can solve problems such as low efficiency and increase processing difficulty, and achieve the effects of improving processing efficiency and simple processing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments. In the description of the present invention, unless otherwise specified, "plurality" means two or more.

[0030] In order to develop the technology of electrical machining of small holes and improve the efficiency of electrical machining of small holes, the current EDM air film hole technology is researched on a mature basis, which can process a row of holes at the same time, and when encountering air film hole processing An improved method of electric discharge machining can be solved when the electrode interferes with the airfoil.

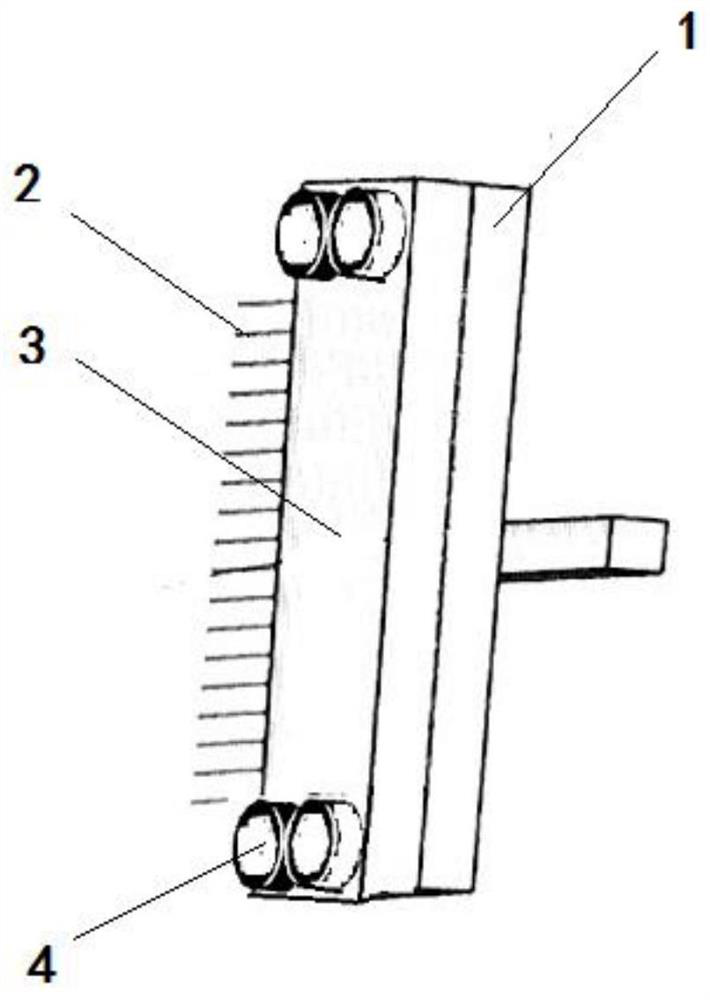

[0031] The air film holes on the blade body are distributed neatly and regularly, generally the entire row is evenly spaced, the angles in a row are usually the same, and there are usually multiple air vent film holes on a blade. According to the arrangement rules of air film holes, design an electrode that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com