Longitudinal-seam laser welding positioning device for thin-wall circular tube

A technology of laser welding and positioning device, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problem that the reliability of positioning accuracy cannot meet the requirements of laser welding process, and achieve good seam effect, low cost and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

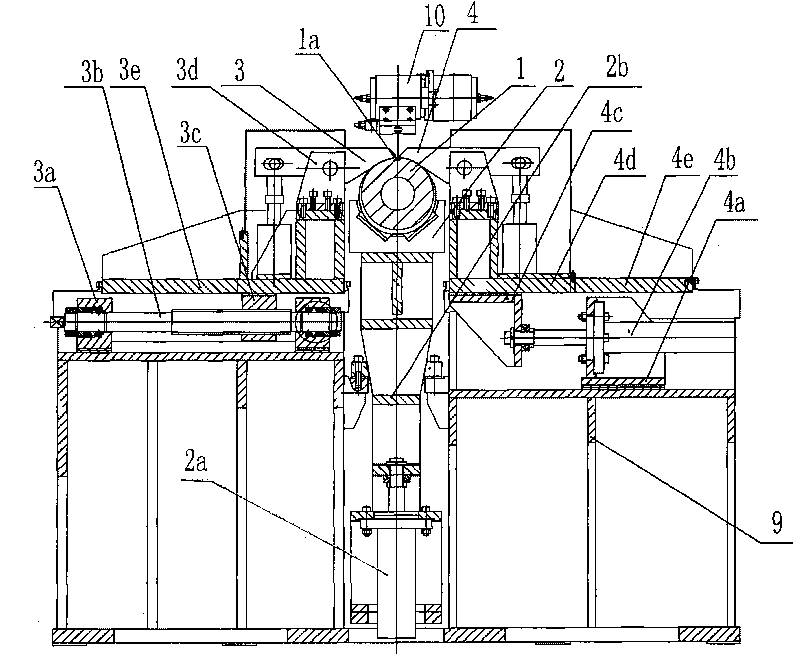

[0020] Further illustrate the concrete structure of the present invention below in conjunction with accompanying drawing:

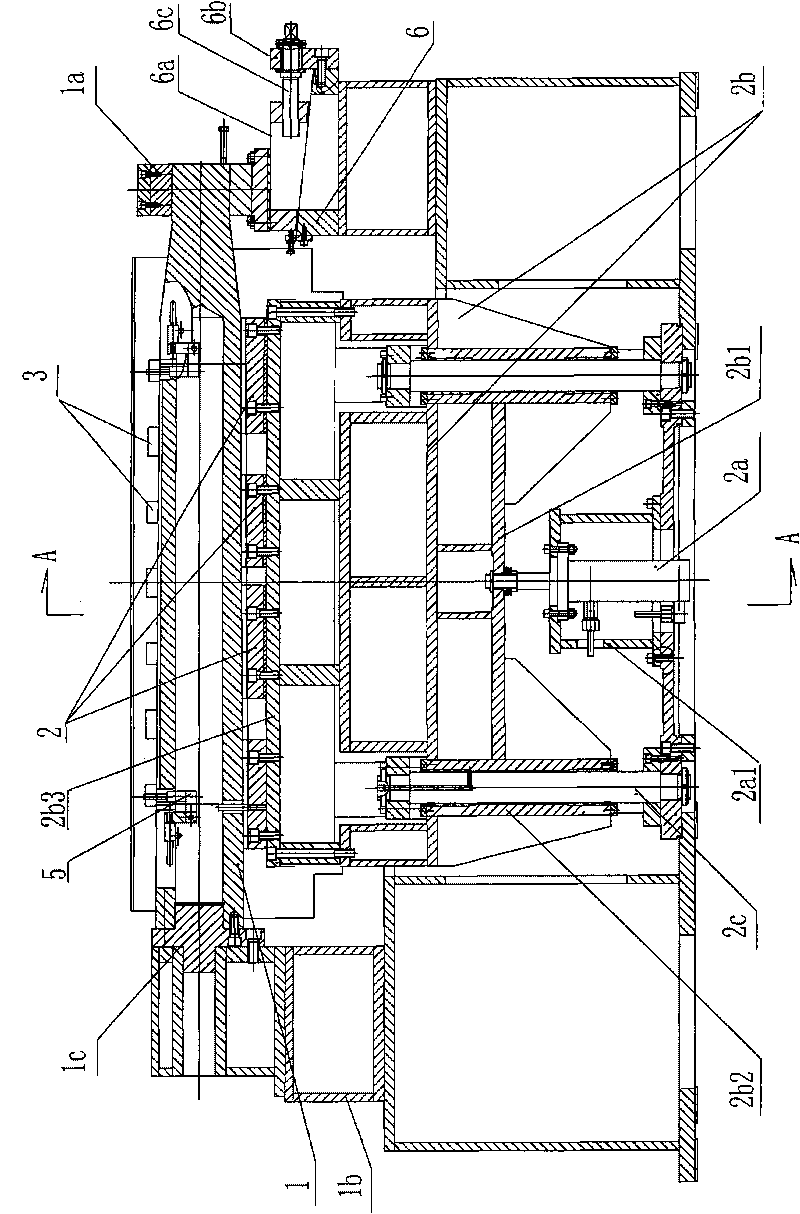

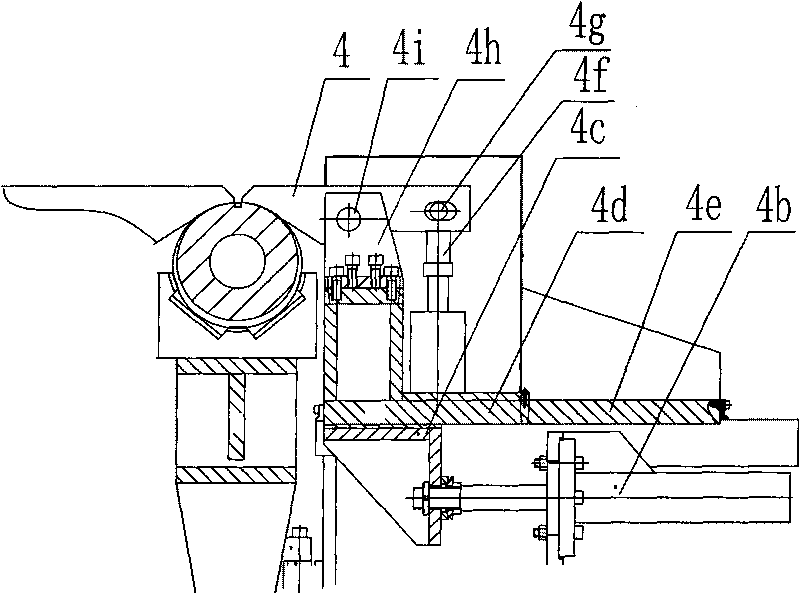

[0021] Such as figure 1 , figure 2 Summary of the invention: The longitudinal seam laser welding positioning device of the thin-walled circular tube provided by the present invention comprises a support mandrel assembly of a formed thin plate, an axial positioning mechanism, a seam positioning mechanism, and a pressing seam mechanism.

[0022] The pressing joint mechanism includes a lower supporting plate 2 and a driving mechanism positioned under the supporting mandrel 1, and left and right claws and a driving mechanism positioned at the left and right sides of the supporting mandrel.

[0023] The driving mechanism of the lower pallet 2 includes a drive cylinder 2a, a lower pallet slide 2b, and front and rear vertical guide rails 2c; the output end of the drive cylinder 2a is connected to the lower part of the lower beam 2b1 of the lower pallet slide 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com