Preparation method of starch modified white carbon black/rubber composite filler

A starch modification and composite filler technology, applied in the rubber field, can solve the problems of limited starch filling amount, long production cycle, complex process, etc., and achieve the improvement of wet skid resistance and wear resistance, low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

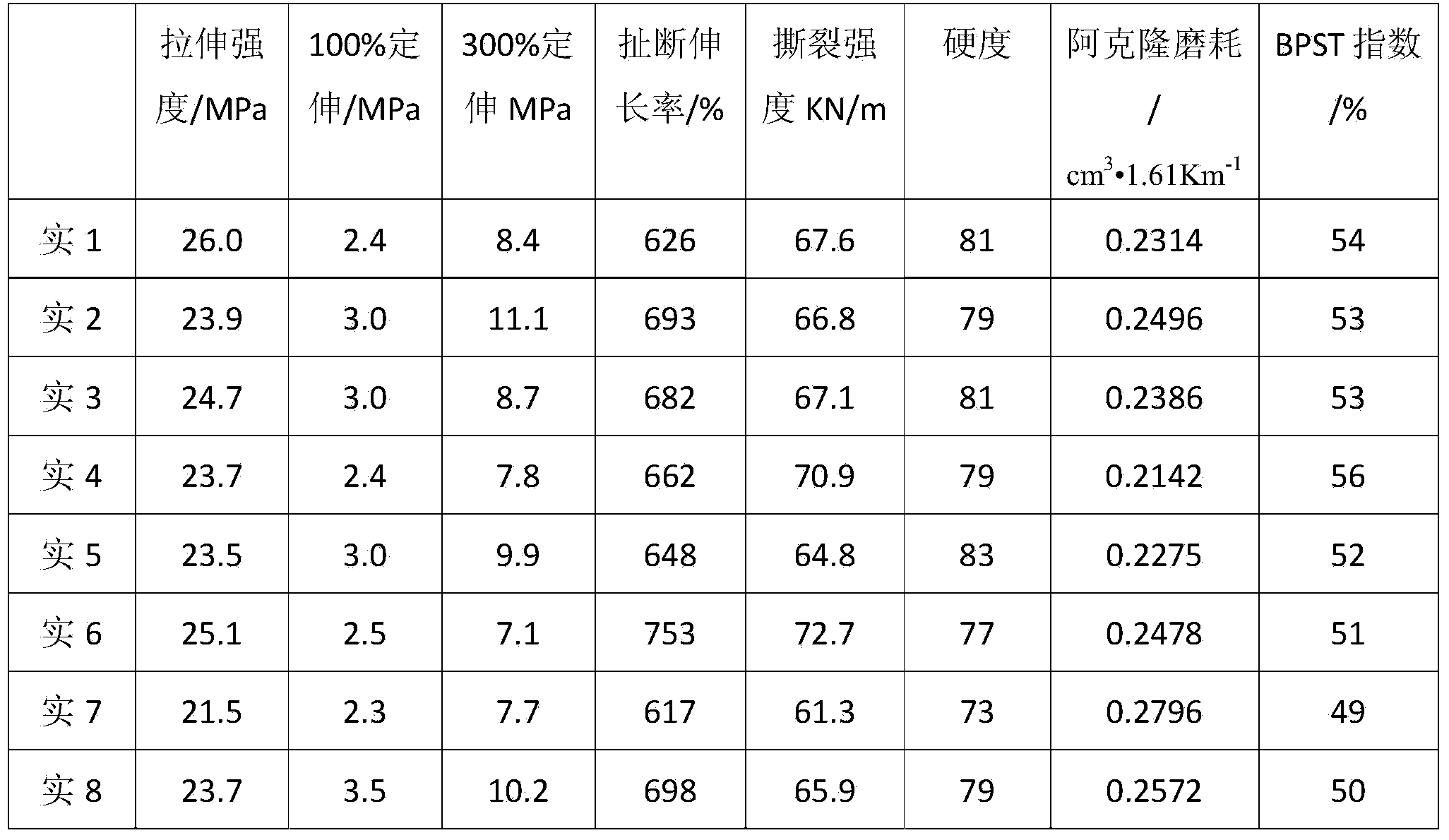

Embodiment 1

[0019] Add 10g of glutinous rice starch into 90g of water and stir evenly to make a starch suspension, gelatinize it under the condition of 80°C for 30min; according to the solid content, take starch paste with a starch content of 10g, in The starch paste was evenly dispersed in the silica / styrene-butadiene rubber composite material on a double-roll mill. The basic formula is shown in Table 3, and the starch-modified silica / styrene-butadiene rubber composite material was obtained, and its properties were measured after vulcanization.

Embodiment 2

[0021] Add 10g of cornstarch into 56.67g of water and stir evenly to make a starch suspension, gelatinize it at 90°C for 20min; according to the solid content, take starch paste with a starch content of 2g, The starch paste was uniformly dispersed in the silica / styrene-butadiene rubber composite material in an internal mixer. The basic formula is shown in Table 3, and the starch-modified silica / styrene-butadiene rubber composite material was obtained, and its properties were measured after vulcanization.

Embodiment 3

[0023] Add 10g of pea starch into 90g of water and stir evenly to make a starch suspension, gelatinize it at 80°C for 30min; according to the solid content, take starch paste with a starch content of 6g, The starch paste was uniformly dispersed in the silica / natural rubber composite material on a double-roll mill. The basic formula is shown in Table 3, and the starch-modified silica / natural rubber composite material was obtained, and its properties were measured after vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com