Flexible heating component machining equipment, machining process and flexible heating component

A technology for processing equipment and heating components, which is applied in the field of processing flexible heating appliances, can solve the problems of limited selection of fabric materials and appearances, labor-intensive, etc., and achieve the goal of overcoming low production efficiency, reducing labor costs, and realizing automated production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

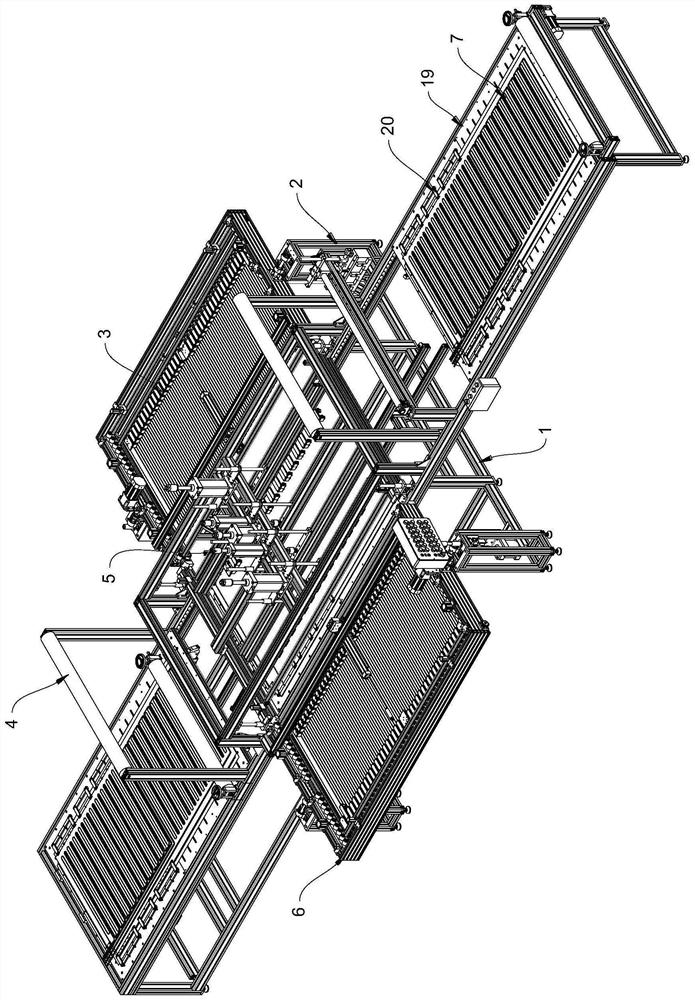

[0052] Please refer to figure 1 , this embodiment provides a flexible heating component processing equipment, including: a frame 1, a glue spraying mechanism 2, a wiring mechanism 3 and a composite mechanism 4.

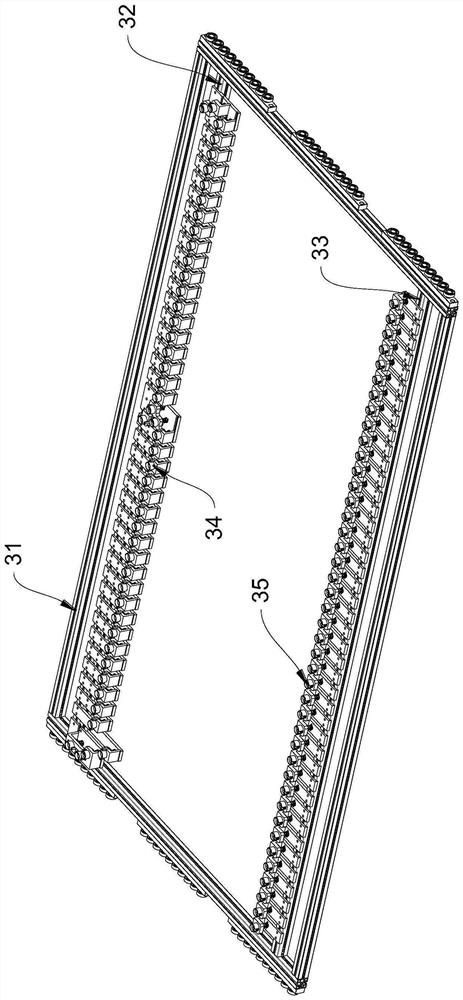

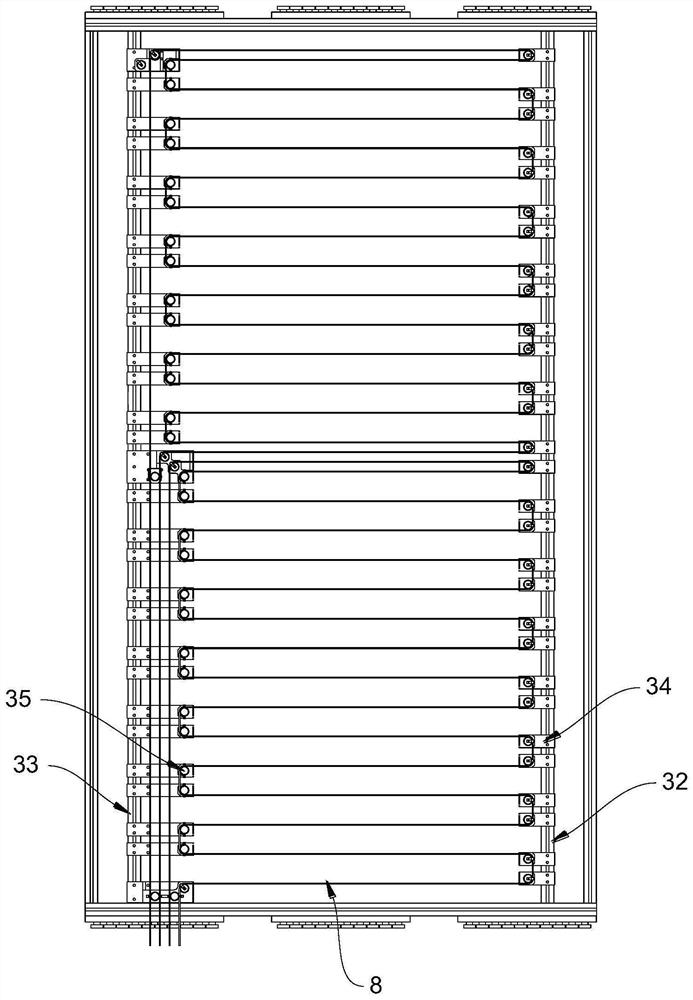

[0053] Among them, the glue spraying mechanism 2 is arranged on the frame 1, and is used for spraying the hot melt glue on the lower fabric 7; The heating area is wrapped around the wiring mechanism 3 to form a heating line layer; the wiring mechanism 3 can be moved on the frame 1 so that the heating line layer is bonded to the lower fabric 7; the composite mechanism 4 is used to attach the upper fabric to the lower fabric 7, to cover the heating wire layer.

[0054] It should be noted that the hot-melt adhesive needs to be heated before spraying (heating temperature is 150°C-200°C), so that the hot-melt adhesive can be melted and sprayed on the lower fabric 7. At the same time, the hot-melt adhesive is wet The gas-curing reactive polyurethane hot melt adhesive ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com