Feeding manipulator of yarn drum covering machine

A technology of manipulators and covering machines, which is applied in the direction of manipulators, program-controlled manipulators, spinning machines, etc. It can solve the problems of inconvenient position movement and achieve the effect of convenient gripping, convenient control and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

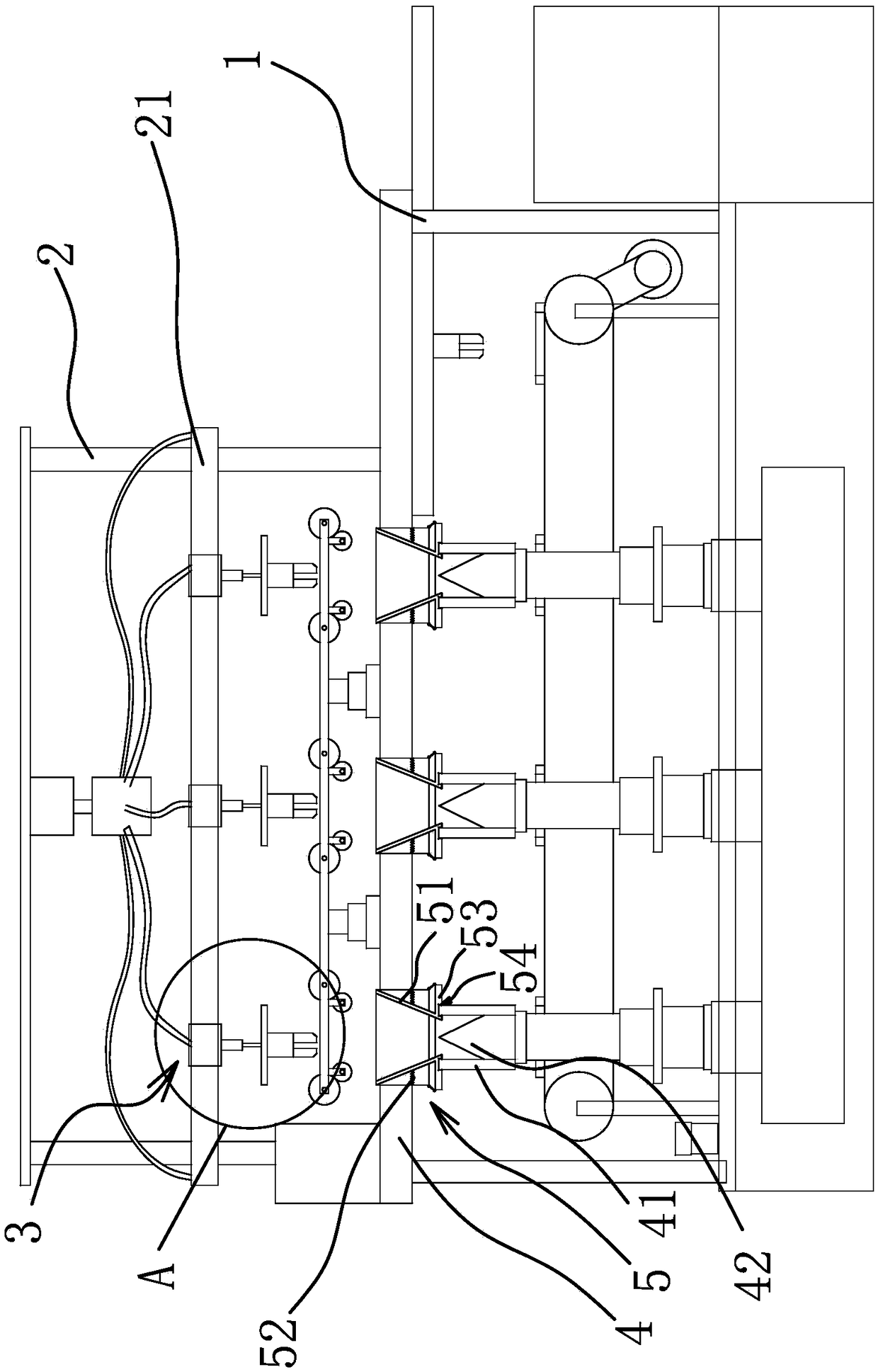

[0018] Such as figure 1 As shown, the feeding manipulator of the bobbin wrapping machine includes a workbench 1 and a support 2, the support 2 is located above the workbench 1, and several feeding manipulators 3 are arranged on the support 2.

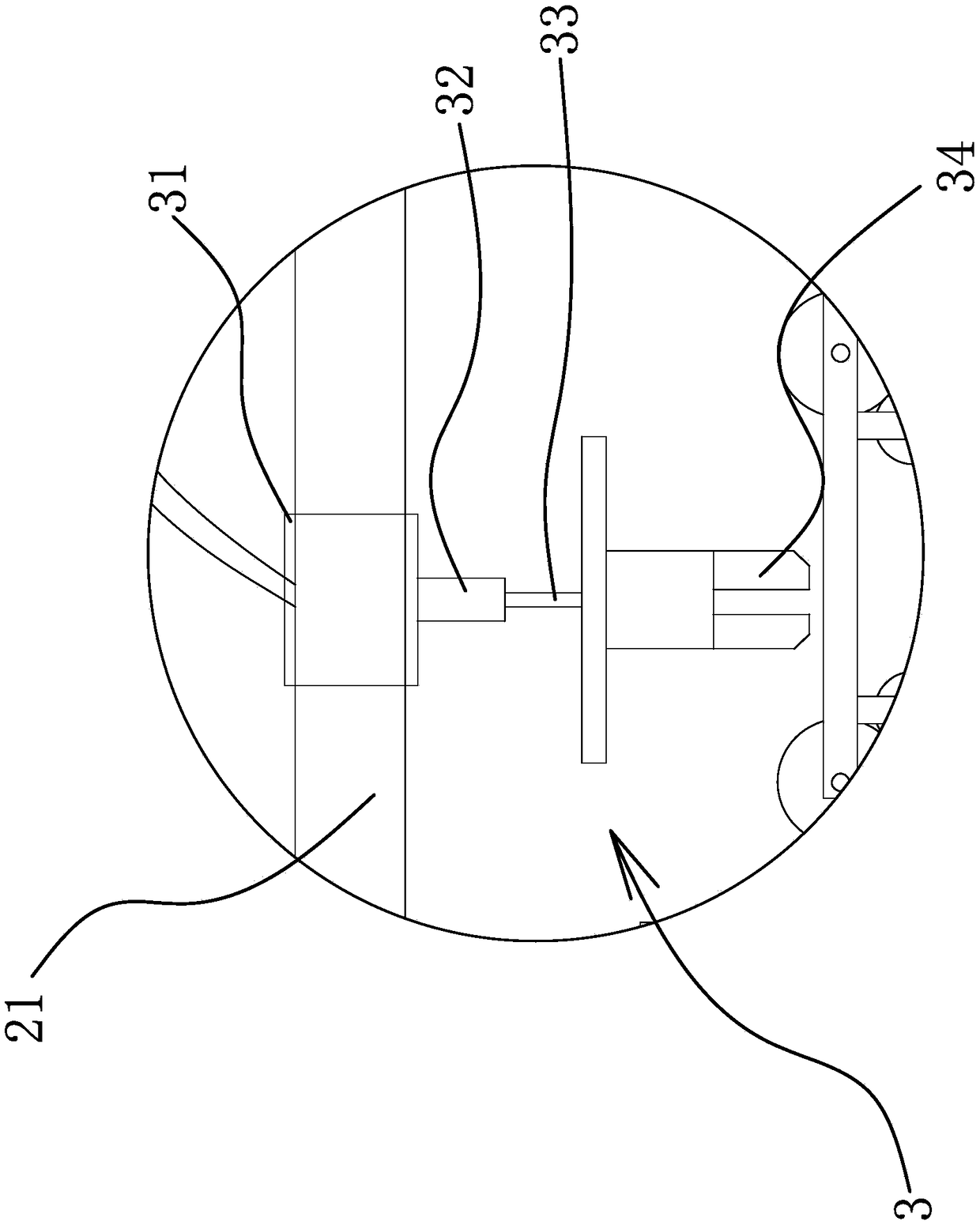

[0019] Specifically, if figure 1 and figure 2 As shown, the support 2 is also provided with a yarn bobbin frame 4, and the feeding manipulator 3 can transport the workpiece to the corresponding yarn bobbin frame 4. It is characterized in that the support 2 is provided with a crossbeam 21, and the feeding manipulator 3 includes Slider 31, cylinder 32 and jaw 34, slider 31 can be sleeved on the beam 21, and slide on the beam 21, cylinder 32 is connected with slider 31, piston rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com