Method for producing microwave-based instant rice

A technology of instant rice and production methods, applied in the field of food processing, can solve the problems of few types of products, labor-intensive and time-consuming production, and nutrient destruction, and achieve the effects of avoiding nutrient loss, avoiding the decline of taste, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

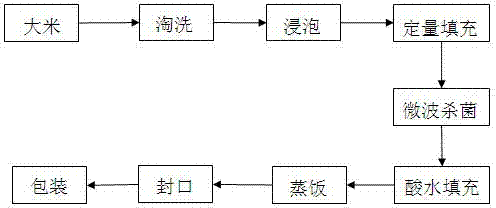

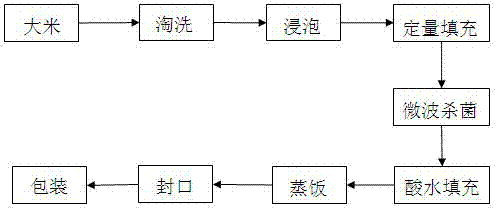

Method used

Image

Examples

Embodiment 1

[0018] Select 200g of high-quality Northeast japonica rice variety Jijing 88, remove broken rice and yellow rice, and remove impurities such as stones in the raw material, and wash it twice with clean water to wash away the dust and impurities on the surface of the rice. Soak the washed rice in water at 50°C for 1 hour to make the rice fully absorb water and facilitate the gelatinization of starch during cooking. Drain the soaked rice, take 100g raw material and fill it in a 500mL PP packaging container. Put the container containing the rice into the microwave device, set the sterilization conditions as 350W, 140°C, and the time as 45s. After sterilization, prepare acid water with glucono-δ-lactone at room temperature, adjust the pH of the filling water to 3.0, add 130g of acid water, and the ratio of rice to water is 1:1.3. Put the raw materials filled with acid water into the steam for cooking. The rice steaming condition is 100-105°C for 30 minutes. After the cooked rice ...

Embodiment 2

[0020] Select 180g of high-quality Northeast japonica rice variety Fujing No. 4, remove broken rice grains and yellow-grained rice, and remove impurities such as stones in the raw materials, and wash 3 times with clean water to remove dust and impurities on the surface of the rice. Soak the washed rice with water at 30°C for 1.5 hours to make the rice fully absorb water and facilitate starch gelatinization during cooking. Drain the soaked rice, take 150g raw material and fill it in a 500mL PP packaging container. Put the container containing the rice into the microwave device, set the sterilization conditions as 450W, 150°C, and 36s. After sterilization, prepare acid water with glucono-δ-lactone at room temperature, adjust the pH of the filling water to 2.8, add 195g of acid water, and the ratio of rice to water is 1:1.3. Put the raw materials filled with acid water into the steam for cooking. The rice steaming condition is 100-105°C for 30 minutes. After the cooked rice is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com