Production method of rice products rich in gamma-aminobutyric acid and products

A technology of GABA rice and GABA, which is applied in the field of food processing, can solve the problems of ineffective activation of enzyme activity, long germination time of brown rice, and low conversion efficiency, and achieve soft color, reduced fat content, and soluble sugar content Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

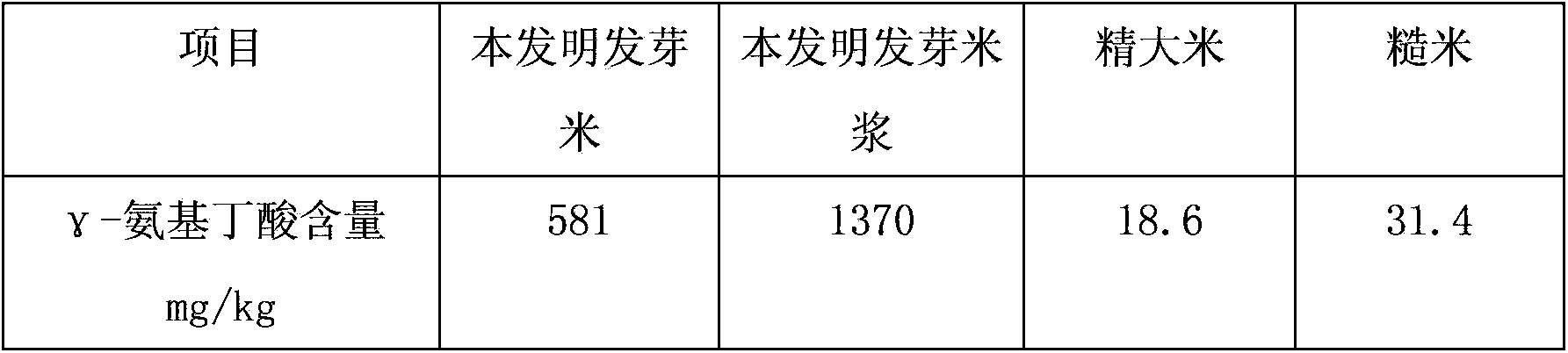

[0034] Embodiment 1: the production of the germinated brown rice of high gamma-aminobutyric acid (GABA)

[0035] Separating the newly harvested paddy huskers and rice paddies to obtain raw brown rice, removing broken grains, moldy grains and heterochromatic grains, disinfecting the raw raw rice with 0.05% sodium hypochlorite solution, and washing away residual sodium hypochlorite components with tap water; The volume ratio of brown rice and calcium chloride solution with a concentration of 0.2% is 4: 1. Soak the raw brown rice at a temperature of 30° C. for 6 hours, wash it with tap water afterwards, and spread the raw brown rice soaked and cleaned On a mesh tray or mesh belt that can drain water, send it to a culture room for cultivation to germinate. Keep it at 90-99% to get germinated brown rice. When using in the next step, the gained germinated brown rice is cleaned 3 times with tap water, part of the germinated brown rice is broken and made into germinated brown rice sl...

Embodiment 2

[0040] Example 2: High γ-aminobutyric acid filling and its application in the production of heart-infused rice rolls and sandwich rice cakes

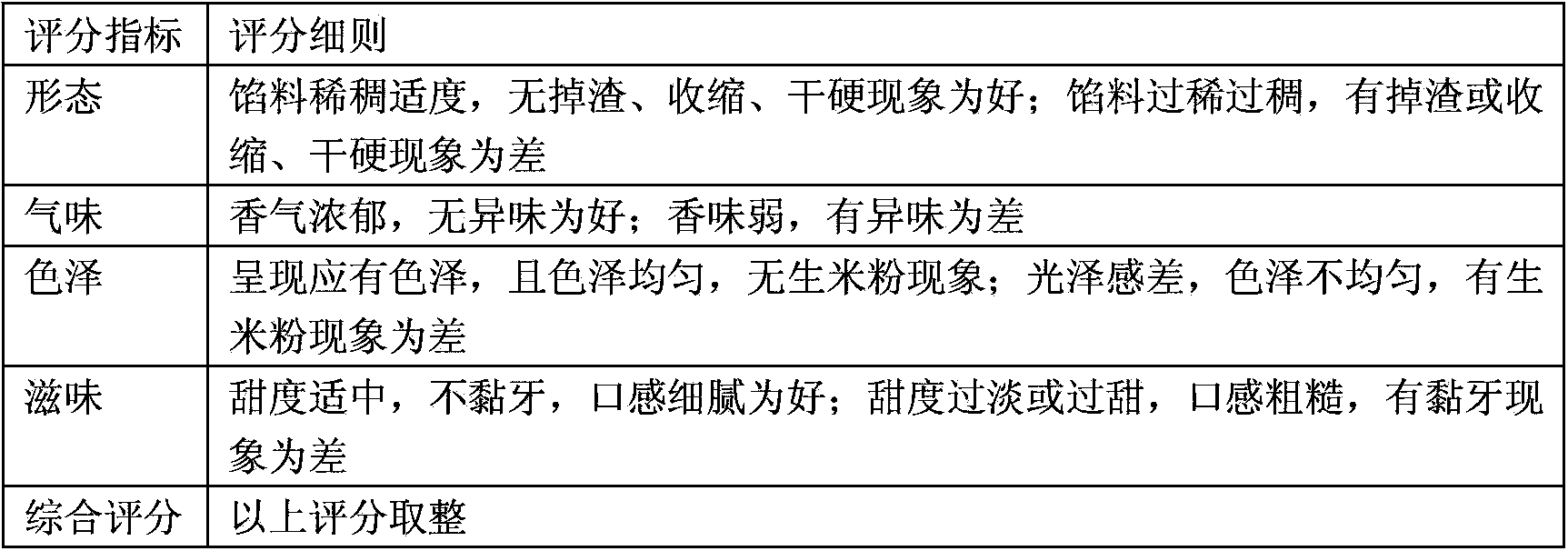

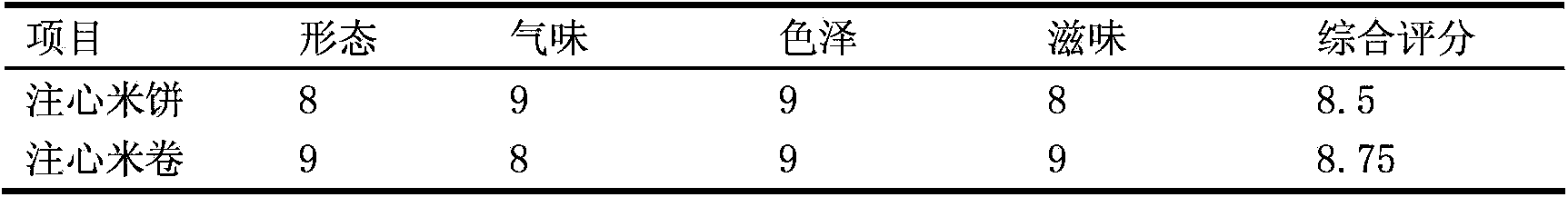

[0041] According to the method of Example 1, after high GABA germinated brown rice milk is prepared, rice milk according to mass ratio: powdered sugar: salt: fat: gum arabic: starch: sodium diacetate: dehydroacetic acid=100: 10: 2: 60 : 14:3:0.04:0.01 The ratio of rice milk is made into fillings; the fillings are poured into the rice roll embryos or sandwiched between two rice cake embryos, and then puffed at 160-180°C to get heart-filled rice rolls and sandwich rice crackers. Carry out sensory evaluation (using five-grade scoring method, and 1-2 points, 3-4 points, 5-6 points, 7-8 points and 9-10 points) Divided into five grades of scoring; the evaluation criteria are shown in Table 2) and the obtained and common fillings, rice rolls and sandwich rice cakes are colorimetrically measured with the gamma-aminobutyric acid assay (Yao Sen,...

Embodiment 3

[0049] Embodiment 3: the production of high gamma-aminobutyric acid (GABA) rice balls, rice sticks, and rice pieces

[0050] Germinated rice was prepared according to the method of Example 1. Steam at 100°C for 45 minutes to steam the rice grains, then dry at 60°C until the water content is below 15% to obtain cooked rice, and puff the cooked rice at 120°C or higher for 57 minutes to obtain puffed rice. Heat the white granulated sugar syrup to 80-90° C., and stick the puffed rice into sticks (or balls or blocks) according to the mass ratio of puffed rice: syrup=100:18 to obtain high-GABA rice sticks, rice balls, and rice nuggets. The rice balls obtained by the method have puffed and plump granules, less cracks on the surface of the rice granules, stronger rice flavor, light yellow color and crisp taste.

[0051] The rice balls obtained by this method and the rice balls made of brown rice and refined rice with the same formula and the same variety were colorimetrically measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com