Method for boiling grains or beans and automatic boiling machine suitable for same

A grain and cooking technology, applied in applications, household utensils, food science, etc., can solve the problems that the nutritional value of grains is difficult to be fully utilized, affects the original taste of grains, and loses nutrients, so as to shorten the exposure time and facilitate promotion Application, the effect of preventing spoilage and fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

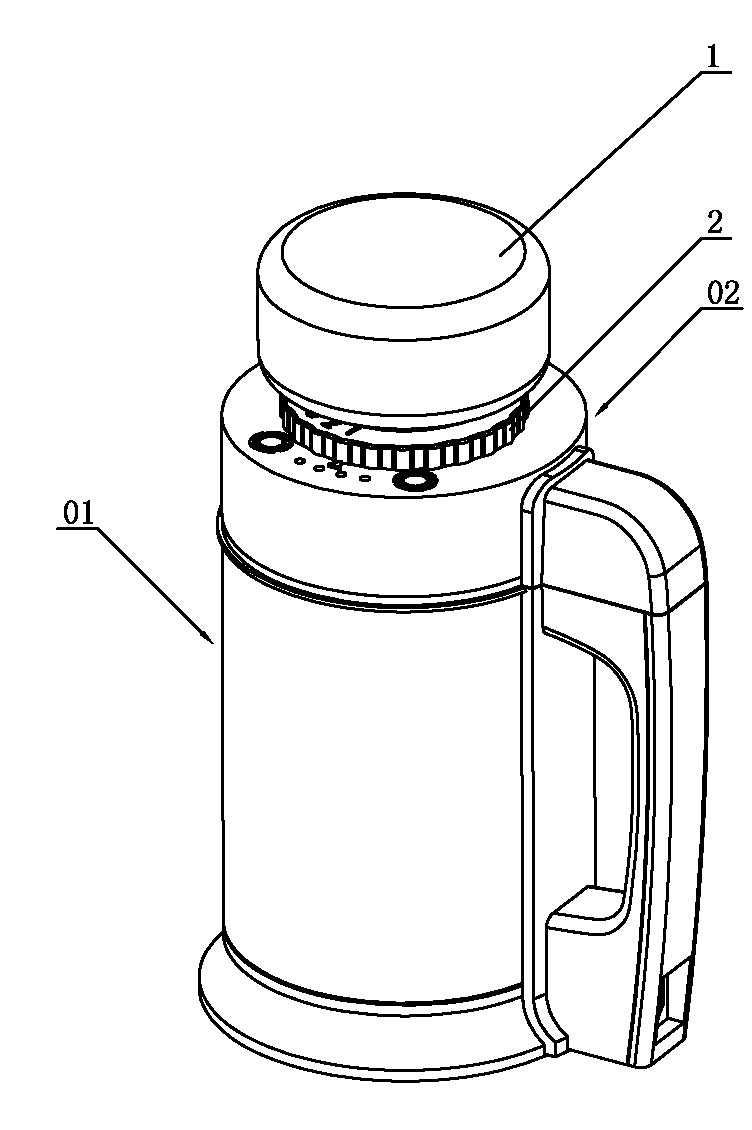

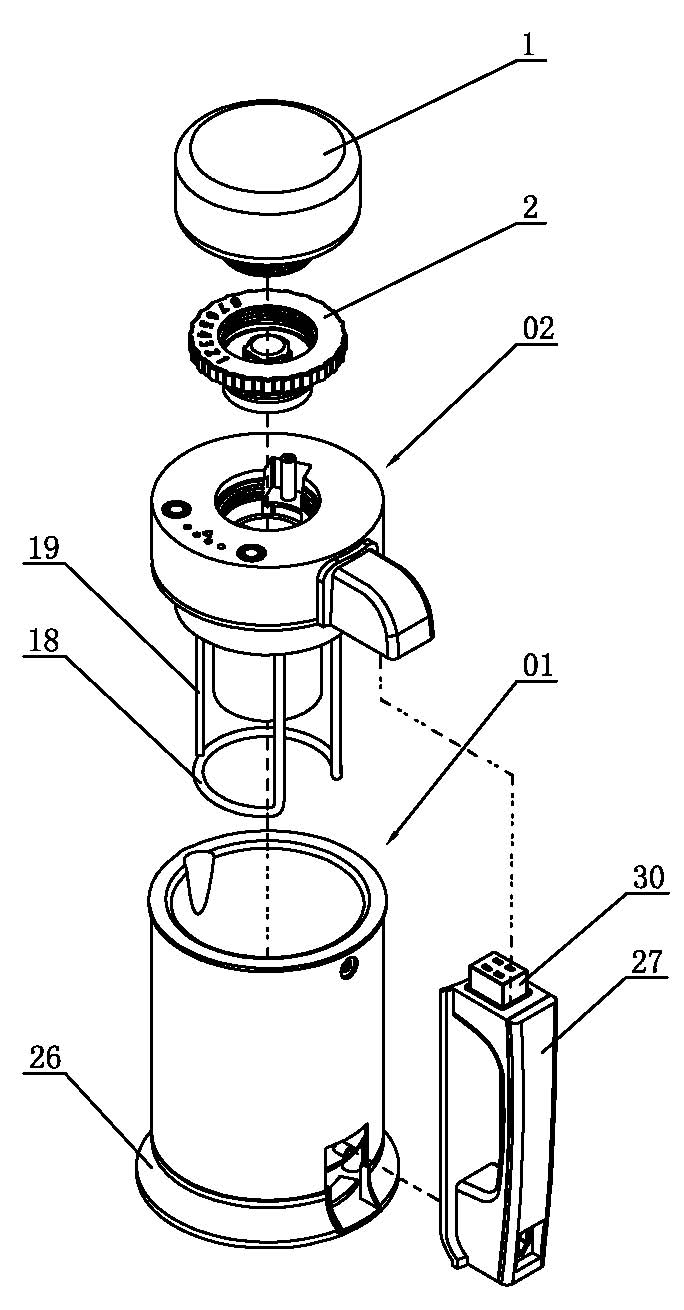

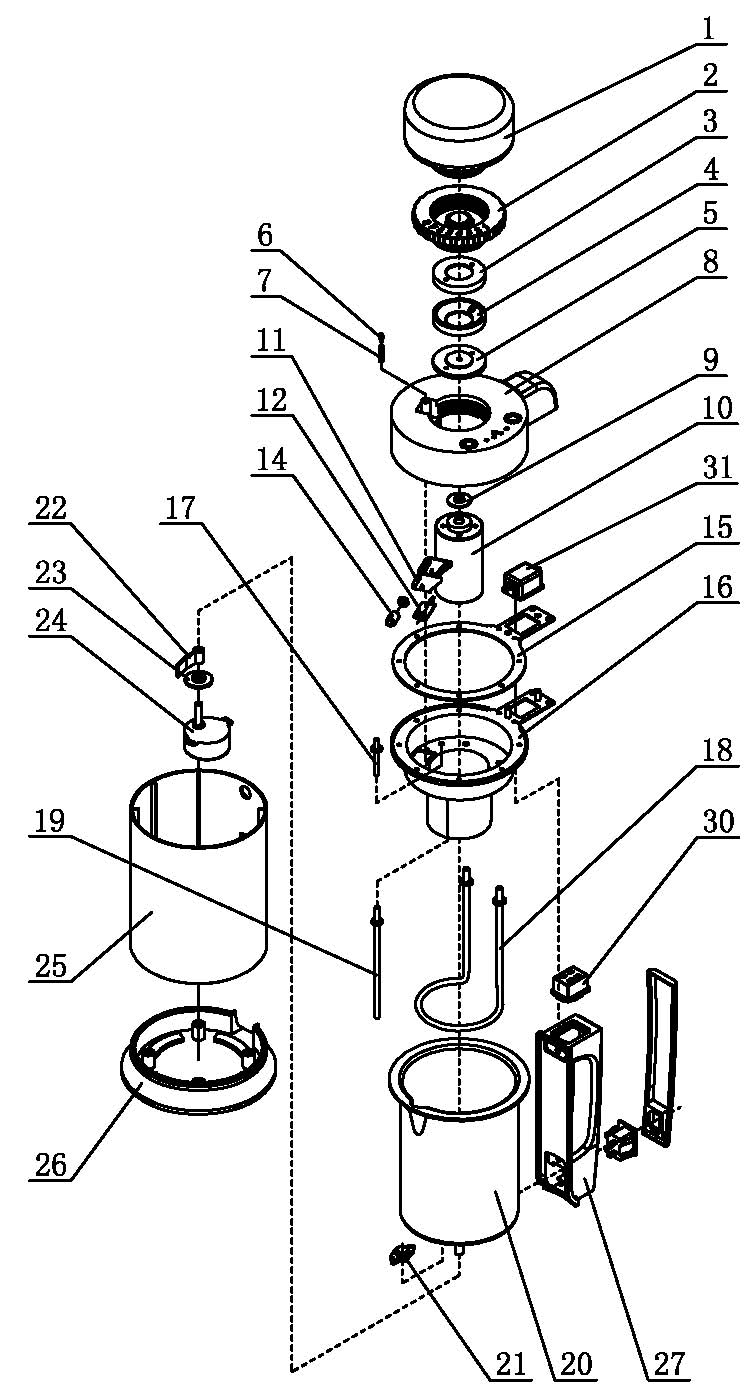

[0046] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0047] A method for cooking grains or beans, the method comprising the following steps: A, adding water into a container for heating, and simultaneously putting the grains or beans into a grinding device; B, waiting for the When the water is heated to hot water with a temperature of 68°C to 90°C, start the grinding device for grinding, and grind the grains or beans into powder particles of the selected thickness; wherein, the specific temperature value of the hot water needs to be Specifically selected according to the nutritional characteristics of different types of grains or beans; C, the powder particles obtained in step B are placed in a container, and the powder particles are mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com