Standardized processing method of instant chicken dish

A processing method and chicken technology, applied in food science, food heat treatment, food ultrasonic treatment and other directions, can solve the problems of chicken nuggets flavor loss, short shelf life, easy deterioration, etc. Taste, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of standardized processing method of instant chicken dish, concrete operation steps are as follows:

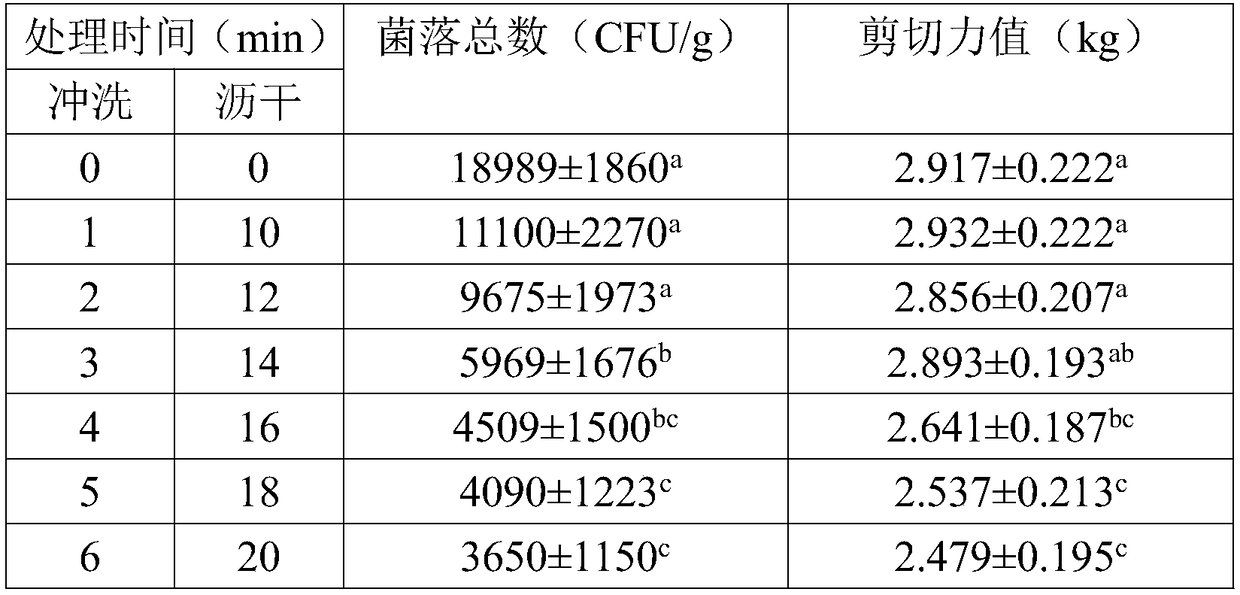

[0037] (1) Pretreatment: Rinse chilled fresh chicken with slightly acidic electrolyzed water with a pH of 6.0 to 6.4 for 1 minute, and drain for 10 minutes for later use;

[0038] (2) Preparation of seasoning powder: Ginger, Chinese prickly ash, star anise, dried chili, dried tangerine peel according to mass ratio are 0.5:0.1:0.05:0.5:1 and use liquid nitrogen freezing pulverizer to beat into powdery mixture, namely seasoning powder A; The scallions and xuelihong are ground into a powdery mixture using the liquid nitrogen freezing grinder according to the mass ratio of 1:1, which is the seasoning powder B;

[0039] (3) Preparation of marinade: mix the seasoning powder B obtained in step (2) with egg white, place in a blender and stir for 2min, the rotating speed is 150r / min, and the mass ratio of the seasoning powder B to egg white is 1 :9, obtain additive Ⅰ;

...

Embodiment 2

[0044] A kind of standardized processing method of instant chicken dish, concrete operation steps are as follows:

[0045] (1) Pretreatment: thaw the frozen chicken naturally in a thawing room at 6°C, rinse with slightly acidic electrolyzed water with a pH of 6.0-6.4 for 2 minutes, and drain for 12 minutes for later use;

[0046] (2) Preparation of seasoning powder: Ginger, Chinese prickly ash, star anise, dried chili, dried tangerine peel according to the mass ratio of 0.7: 0.1: 0.08: 1: 1 are ground into a powdery mixture using a liquid nitrogen freezing grinder, which is seasoning powder A; The scallions and xuelihong are ground into a powder mixture using the liquid nitrogen freezing grinder according to the mass ratio of 1:1.3, which is seasoning powder B;

[0047] (3) Preparation of marinade: mix the seasoning powder B obtained in step (2) with egg white, place in a blender and stir for 3 minutes, the rotating speed is 180r / min, and the mass ratio of the seasoning powder...

Embodiment 3

[0052] A standardized processing method for instant chicken dishes, the specific operation steps are the same as in Example 2, but different from Example 2, in this example, in step (2), ginger, Chinese prickly ash, star anise, dried chili , The mass ratio of tangerine peel is 0.7:0.2:0.1:1.5:2. In seasoning powder B, the weight ratio of scallions: xuelihong is 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com