Shelling and cold-pressing integrated device used for production of camellia oil

A camellia oil and shell technology, which is applied in the direction of fat oil/fat production and fat production, can solve problems such as troubles, and achieve the effect of simple process, simple structure and simplified production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

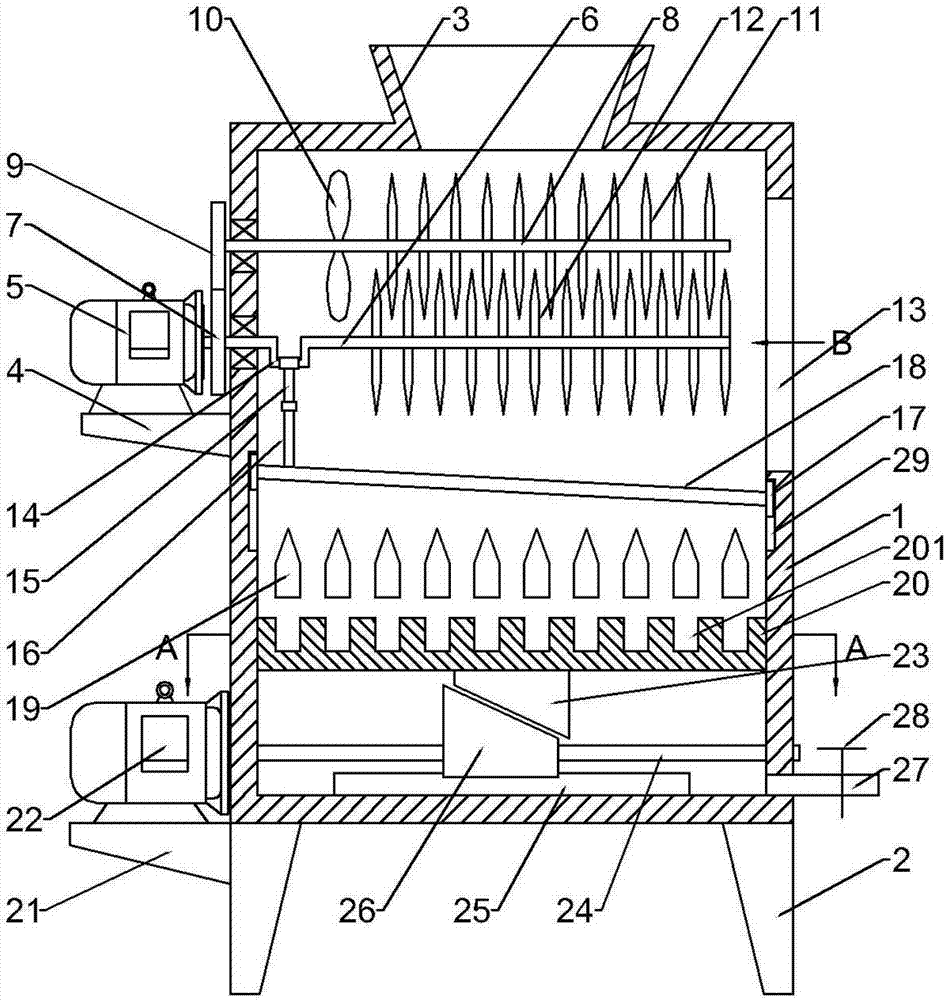

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

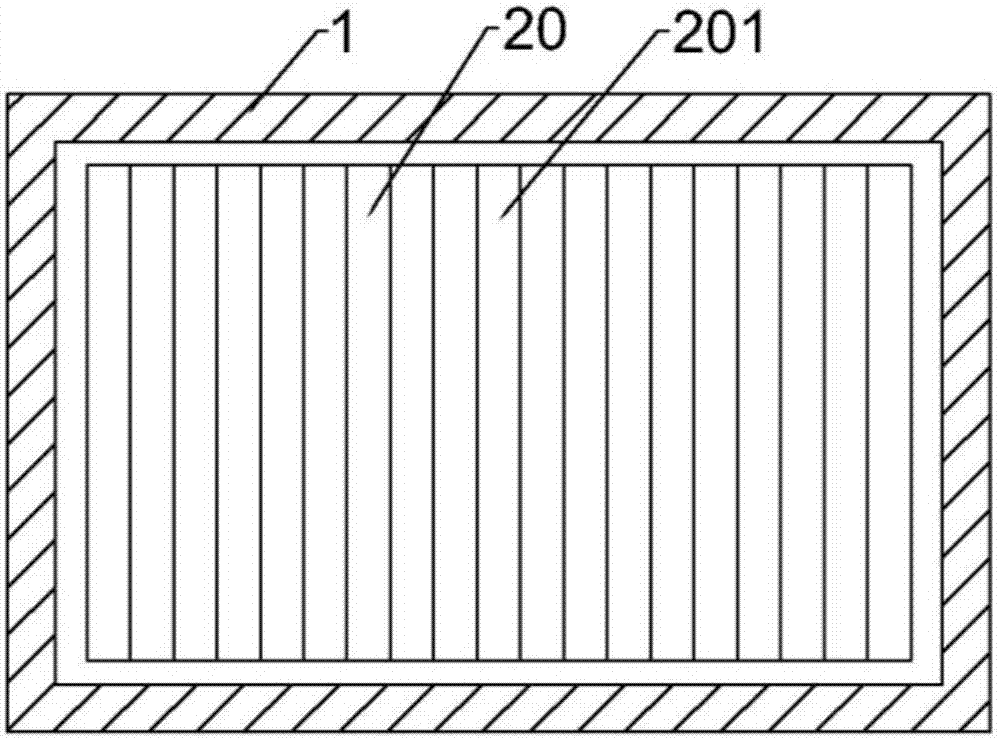

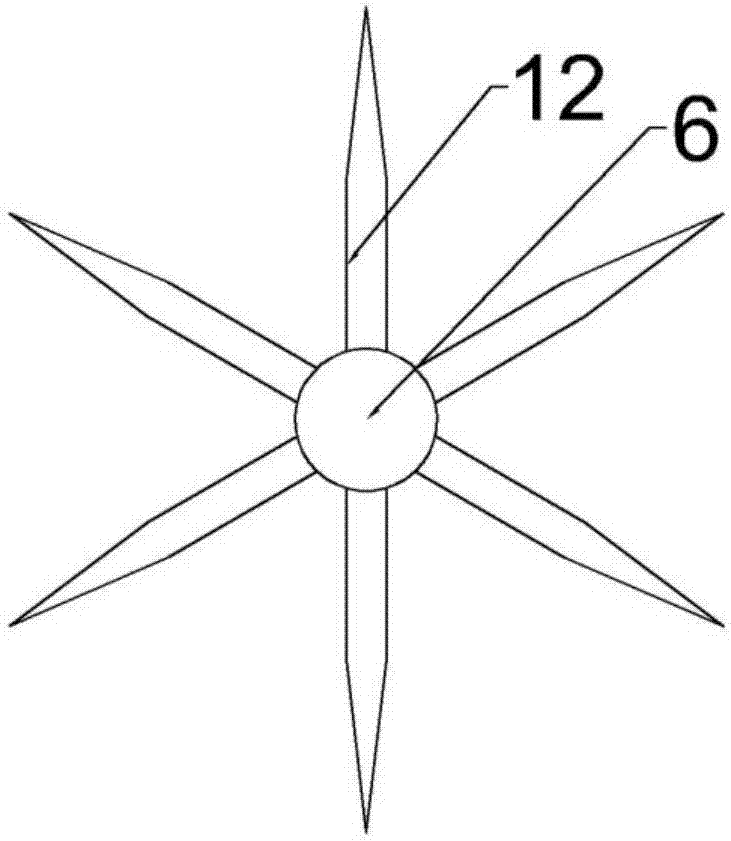

[0021] see Figure 1-3 , a kind of shelling and cold pressing integrated equipment for camellia oil production, comprising a shell 1, the cross-section of the shell 1 is rectangular, the top of the shell 1 is fixedly connected with a feeding funnel 3, the upper left side of the shell 1 The first motor base 4 is fixedly connected, the first motor base 4 is fixedly connected with the housing 1 by bolts, the first motor 5 is fixedly connected above the first motor base 4, and the lower shaft 6 is rotationally connected above the inside of the housing 1 , the left end of the lower rotating shaft 6 is fixedly connected to the output end of the first motor 5, the left side of the lower rotating shaft 6 is fixedly connected with the driving gear 7, and the upper rotating shaft 6 is forwardly connected with the upper rotating shaft 8, and the left end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com