Refining process of original sweet tea seed oil via low-temperature physical membrane method

A kind of physical and seed oil technology, which is applied in the refining process of original tea seed oil, can solve the problems of easy loss of active nutrients and natural fragrance, high energy consumption, etc., and achieve the effect of saving refining cost and good food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

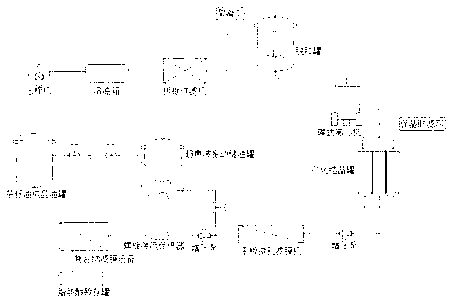

Method used

Image

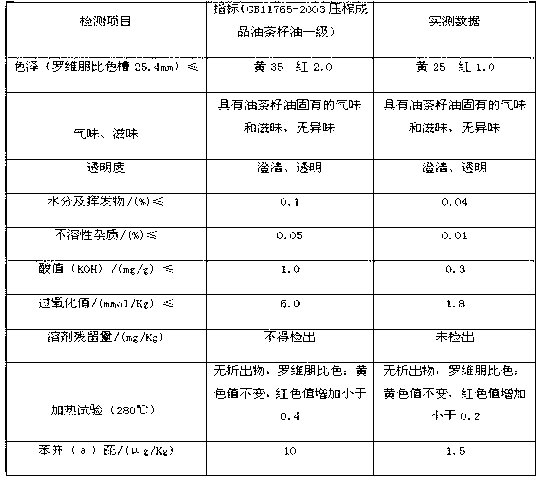

Examples

Embodiment 1

[0023] 1. Squeeze and filter: After cleaning and peeling the dried camellia seed, put it directly into the press machine for physical pressing, and the obtained residue-containing oil is processed in the oil tank and then pumped into the plate and frame filter for filtration, that is, the raw tea seed oil is obtained. Fragrant filtered crude oil;

[0024] 2. Degumming: Put the filtered crude oil into the degumming tank with a pump, add 0.2% flocculant based on the weight of the crude oil and stir for 20 minutes, then separate and degumming through a disc centrifuge. The flocculant is a mixture of phosphoric acid solution and salt. The mixing ratio of phosphoric acid and table salt is 1:15.

[0025] 3. Dewaxing: Add 0.1% of the weight of crude oil to the degummed crude oil to carry out winterization and crystallization. After 24 hours of crystal growth, the dewaxed crude oil is separated by a flat microporous membrane filter, and added The crystal-stimulating filter aid is a m...

Embodiment 2

[0032] 1. Squeeze and filter: After cleaning and peeling the dried camellia seed, put it directly into the press machine for physical pressing, and the obtained residue-containing oil is processed in the oil tank and then pumped into the plate and frame filter for filtration, that is, the raw tea seed oil is obtained. Fragrant filtered crude oil;

[0033] 2. Degumming: pump the filtered crude oil into the degumming tank, add 0.15% flocculant based on the weight of the crude oil and stir for 30 minutes, then separate and degumming through a disc centrifuge. The flocculant is a mixture of phosphoric acid solution and salt. The mixing ratio of phosphoric acid and table salt is 1:10.

[0034] 3. Dewaxing: add 0.2% of the weight of the crude oil to the degummed crude oil for winterization and crystallization. After 18 hours of crystal growth, the dewaxed crude oil is separated by a flat microporous membrane filter. The crystal-stimulating filter aid added is a mixture of perlite a...

Embodiment 3

[0041] 1. Squeeze and filter: After cleaning and peeling the dried camellia seed, put it directly into the press machine for physical pressing, and the obtained residue-containing oil is processed in the oil tank and then pumped into the plate and frame filter for filtration, that is, the raw tea seed oil is obtained. Fragrant filtered crude oil;

[0042] 2. Degumming: Put the filtered crude oil into the degumming tank with a pump, add 0.3% flocculant based on the weight of the crude oil and stir for 20 minutes, then separate and degumming through a disc centrifuge. The flocculant is a mixture of phosphoric acid solution and salt. The mixing ratio of phosphoric acid and table salt is 1:18.

[0043] 3. Dewaxing: Add 0.25% of the weight of the crude oil to the degummed crude oil for winterization and crystallization. After 24 hours of crystal growth, the dewaxed crude oil is separated by a flat microporous membrane filter. The crystal-stimulating filter aid added is a mixture o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com