Vegetable oil deodorizing, deacidifying and refining device and process

A refining device and vegetable oil technology, applied in the field of vegetable oil refining, can solve the problems of uncontrollable oil plasticizer trans fatty acid content, energy consumption, poor time and temperature operability, etc., achieve flexible deacidification and deodorization process, and increase heat Utilization rate, the effect of making full use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

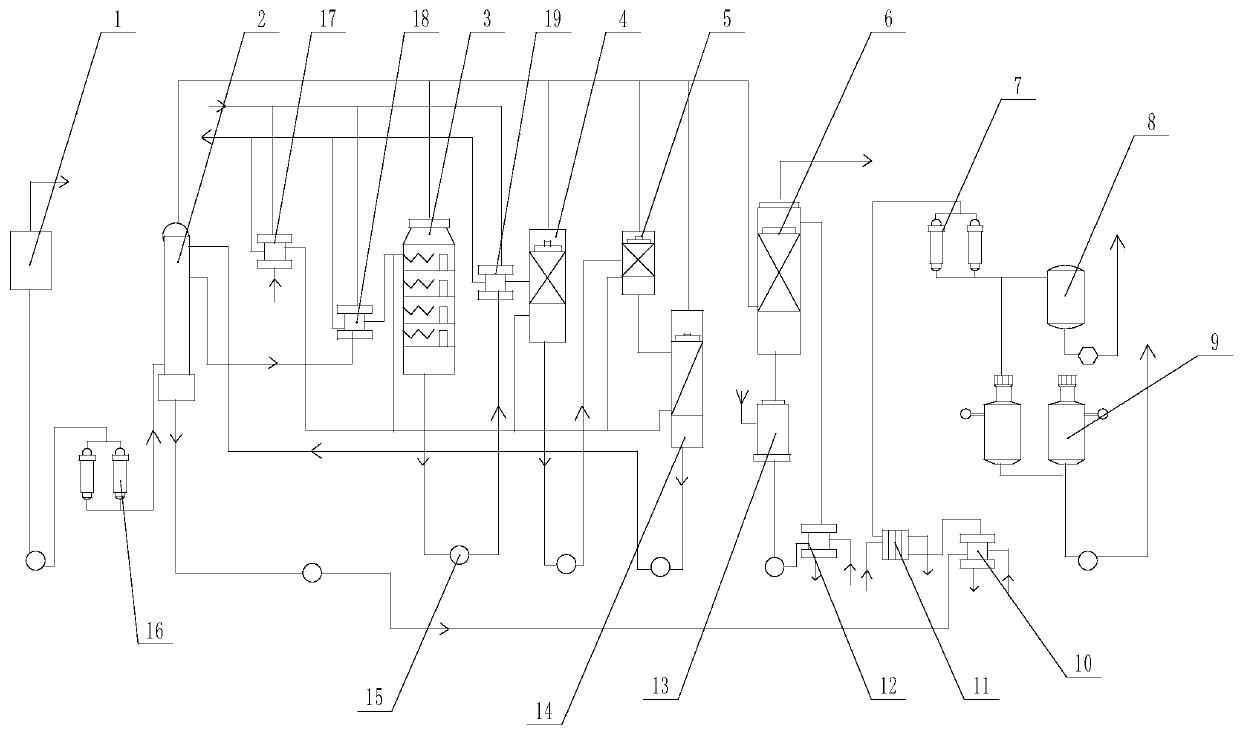

[0031] Described vegetable oil deodorization, deacidification refining device comprises deodorization tower (3) and deacidification tower, also comprises gas separator (1) and falling film heat exchanger (2), described gas separator (1), Falling film heat exchanger (2), deodorization tower (3) and deacidification tower are connected through pipeline successively, and deacidification tower is connected with product oil temporary storage tank (8) through pipeline; A filter I (16) is provided between the membrane heat exchanger (2), a heater I (18) is provided between the falling film heat exchanger (2) and the deodorization tower (3), and the deodorization tower (3) Heater II (19) is arranged between the deacidification tower and the falling film heat exchanger (2), the deodorization tower (3) and the upper gas outlet of the deacidification tower are respectively connected with the fatty acid capture tower (6) , the lower outlet of the fatty acid trapping tower (6) is connected ...

Embodiment 2

[0033] The vegetable oil deodorization and deacidification refining device includes a deodorization tower (3) and a deacidification tower, and the deacidification tower includes No. I deacidification tower (4), No. II deacidification tower (5) and III No. deacidification tower (14), also comprises gas separator (1) and falling film heat exchanger (2), described gas separator (1), falling film heat exchanger (2), deodorization tower (3 ) and the deacidification tower are connected through pipelines in turn, and the oil outlet of No. Ⅲ deacidification tower (14) is connected to the oil inlet of the falling film heat exchanger (2), and the finished oil after heat exchange enters the finished product through the pipeline. Oil temporary storage tank (8); filter I (16) is arranged between the gas analyzer (1) and the falling film heat exchanger (2), the falling film heat exchanger (2) and the deodorization tower ( 3) Heater I (18) is arranged between, and heater II (19) is arranged ...

Embodiment 3

[0035] The vegetable oil deodorization and deacidification refining device includes a deodorization tower (3) and a deacidification tower, and the deacidification tower includes No. I deacidification tower (4), No. II deacidification tower (5) and III No. deacidification tower (14), also comprises gas separator (1) and falling film heat exchanger (2), described gas separator (1), falling film heat exchanger (2), deodorization tower (3 ) and the deacidification tower are connected through pipelines in turn, and the oil outlet of No. Ⅲ deacidification tower (14) is connected to the oil inlet of the falling film heat exchanger (2), and the finished oil after heat exchange enters the finished product through the pipeline. Temporary oil storage tank (8); No. Ⅰ product oil cooler (10) and No. Ⅱ product oil cooler ( 11), filter II (7); the temporary oil product storage tank (8) is connected with the oil product storage tank (9).

[0036] A filter I (16) is provided between the gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com