A method for reducing trans fatty acids

A technology of trans fatty acid and oil, which is applied in the direction of producing fat, fat oil/fat refining, etc. It can solve the problems of difficulty in industrialization, reduction of deodorization process temperature and time, and difficulty in industrial production, so as to suppress trans fatty acid and avoid disadvantages Influencing and improving the effect of food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

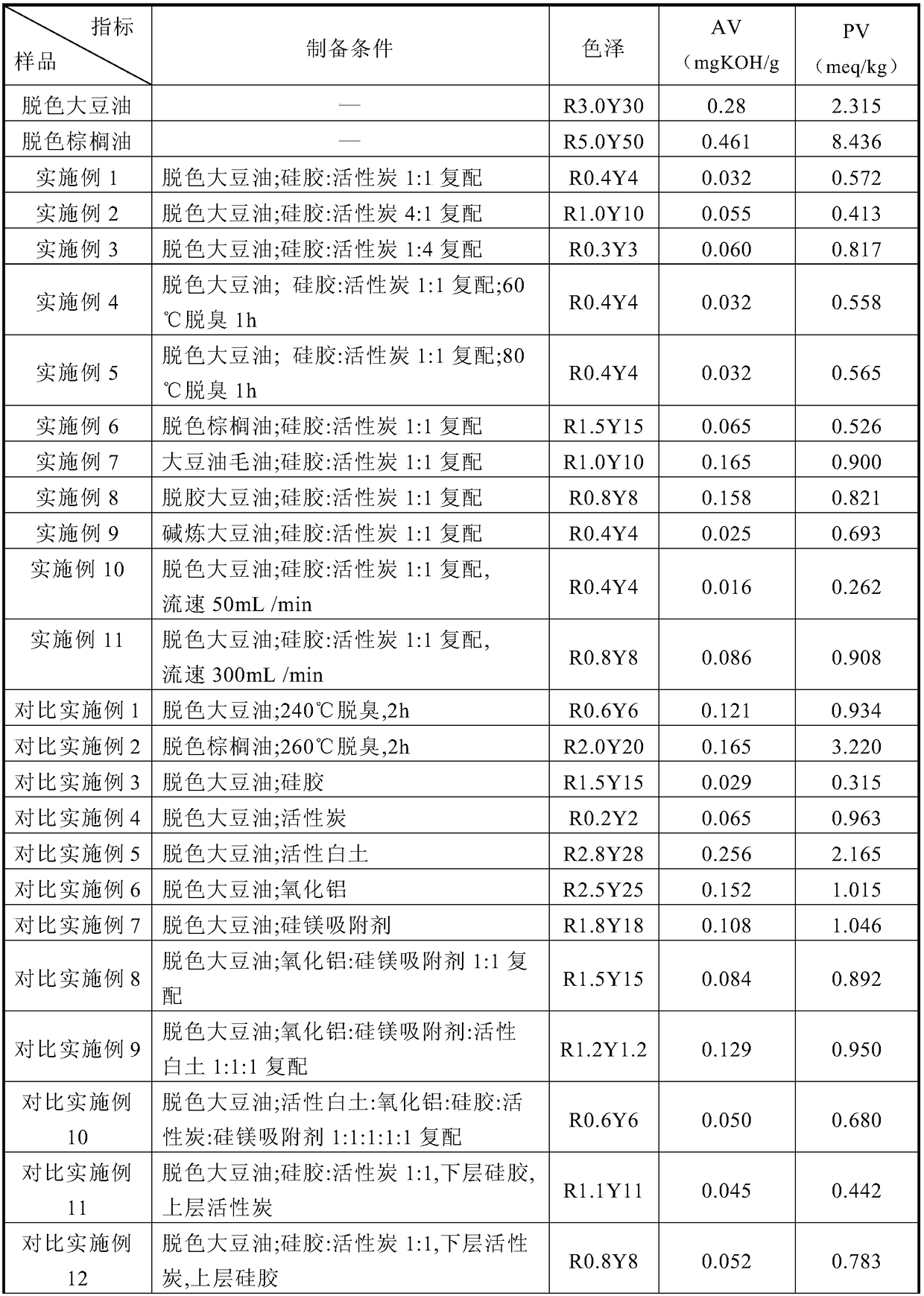

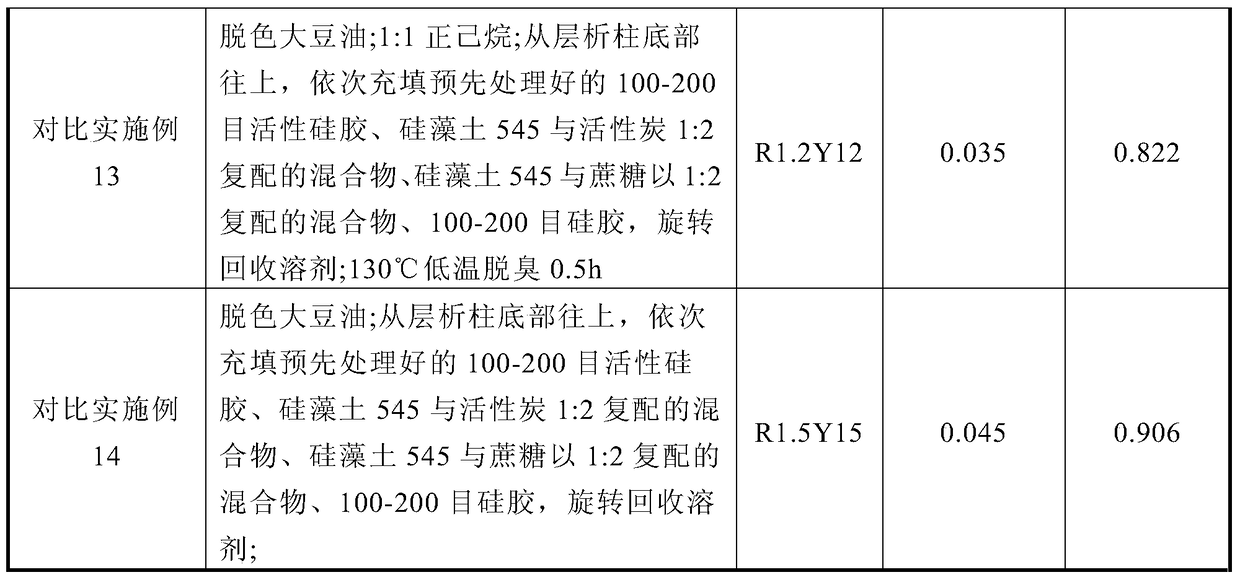

Embodiment 1

[0061] Use silica gel and activated carbon at a ratio of 1:1, mix well as an adsorbent, dry-load it into a chromatography column, and use a metering pump to inject decolorized soybean oil into the chromatography column at a flow rate of 150mL / min. And the pipeline pressure is 10-20 bar, the chromatographic column pressure is 20-30 bar, and the oil sample is collected to obtain the prepared oil sample. The chromatographic process does not need to fill with nitrogen or oxygen, and does not need to be heated in a water bath. In the following examples and comparative examples, except for the injection of solid fats such as decolorized palm oil, the operation process is the same.

Embodiment 2

[0063] Use silica gel and activated carbon at a ratio of 4:1, mix well as an adsorbent, dry-load it into a chromatographic column, use a metering pump to inject decolorized soybean oil into the chromatographic column at a flow rate of 150mL / min, and collect oil samples. The prepared oil sample was obtained.

Embodiment 3

[0065] Use silica gel and activated carbon at a ratio of 1:4, mix well as an adsorbent, dry-load it into a chromatographic column, use a metering pump to inject decolorized soybean oil into the chromatographic column at a flow rate of 150mL / min, and collect oil samples. The prepared oil sample was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com