A method for curing diamond resin wire by microwave-ultraviolet light combination

A technology of diamond resin wire and ultraviolet light, which is applied in the direction of chemical instruments and methods, chemical/physical/physicochemical processes of energy application, chemical/physical processes, etc., can solve the problem of difficult uniform and complete resin curing, long electrothermal curing time, High production cost and other issues, to achieve the effect of shortening drying time, small surface damage, and small deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

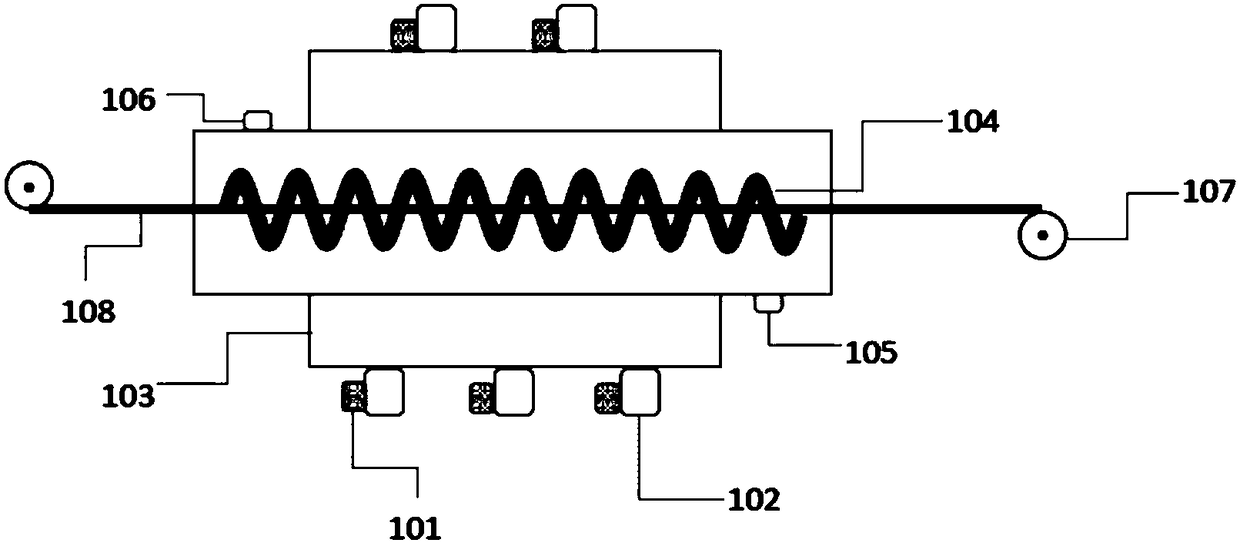

Image

Examples

Embodiment 1

[0042] The concrete steps of the method for solidifying the diamond resin wire by combining microwave-ultraviolet light of the present invention are as follows:

[0043] (1) mixing the heat-curable resin and the light-curable resin to form a mixed resin;

[0044] (2) the diamond particles are made into a slurry according to the volume ratio of 1% and the mixed resin;

[0045] (3) uniformly coating the slurry on the surface of the metal core wire to obtain a resin wire;

[0046] (4) Curing the resin wire through a curing device containing microwaves and ultraviolet light, controlling the microwave energy field and the luminous intensity of ultraviolet light by adjusting the microwave power, to obtain a cured diamond resin wire;

[0047] (5) The cured diamond resin wire is dried to obtain the final product.

[0048] In step (1), the thermosetting resin is phenolic resin; the photocuring resin is polyurethane acrylic resin; the volume ratio of the two is 2:1.

[0049] In step ...

Embodiment 2

[0053] The concrete steps of the method for solidifying the diamond resin wire by combining microwave-ultraviolet light of the present invention are as follows:

[0054] (1) mixing the heat-curable resin and the light-curable resin to form a mixed resin;

[0055] (2) the diamond particles are made into a slurry according to the volume ratio of 30% and the mixed resin;

[0056] (3) uniformly coating the slurry on the surface of the metal core wire to obtain a resin wire;

[0057] (4) Curing the resin wire through a curing device containing microwaves and ultraviolet light, controlling the microwave energy field and the luminous intensity of ultraviolet light by adjusting the microwave power, to obtain a cured diamond resin wire;

[0058] (5) The cured diamond resin wire is dried to obtain the final product.

[0059] In step (1), the thermosetting resin is polyester resin and polyamide resin; the photocuring resin is epoxy acrylic resin; the volume ratio of the three is 5:3:6....

Embodiment 3

[0064] The concrete steps of the method for solidifying the diamond resin wire by combining microwave-ultraviolet light of the present invention are as follows:

[0065] (1) According to the volume ratio, epoxy resin and novolac epoxy acrylic resin are configured into mixed resin with a ratio of 1:1;

[0066] (2) Take 150 / 125 mesh diamond as an example, add 15% by volume to the prepared mixed resin;

[0067] (3) take the metal twisted pair as the core wire, and its diameter is 200 microns. After surface washing and activation treatment, the diamond resin obtained above is coated on the core wire surface, and then through the 230 micron diameter limiting mold, the The resin wire is wound into the microwave-ultraviolet combined device system;

[0068] (4) Pass the resin line through the microwave-ultraviolet combined device at a speed of 2m / s, wherein the microwave power is 0.2w / cm 2 , the intensity of ultraviolet light is 120w / cm 2 ;

[0069] (5) The obtained diamond resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com