Motorcycle brake disc

A brake and brake disc technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of poor precision and high brake disc processing costs, reduce manufacturing costs, reduce personnel labor costs and The effect of investing capital and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

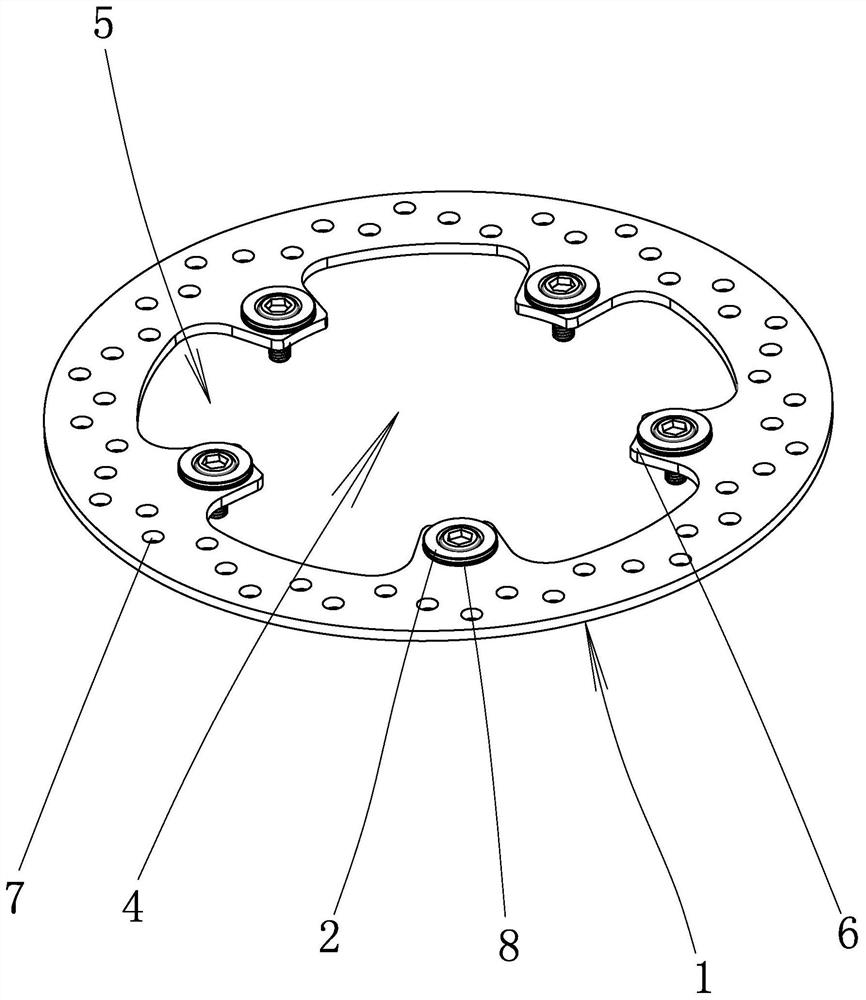

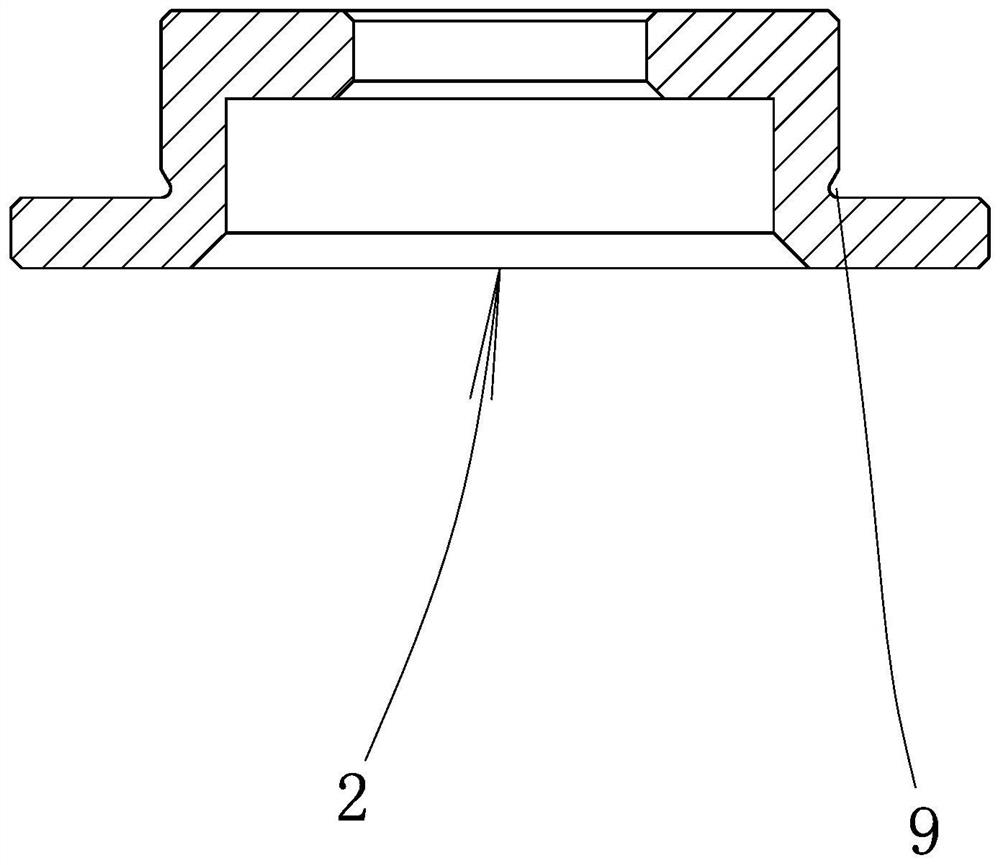

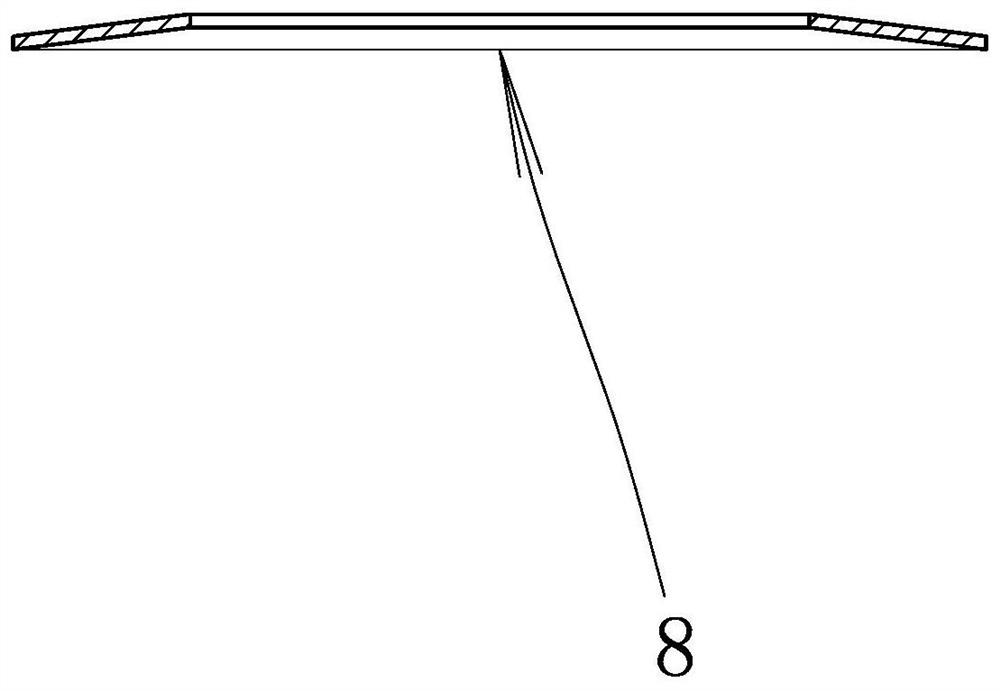

[0017] Such as figure 1 figure 2 image 3 As shown, the motorcycle brake disc includes a brake disc body 1 and a rivet 2. The brake disc body 1 is provided with several mounting holes 3 for the rivets 2 to be installed, and the middle part of the brake disc body 1 is provided with a central hole 4. , The central hole 4 is provided with several fan-shaped grooves 5 distributed along its inner wall, and there is a raised portion 6 between the two spaced fan-shaped grooves 5, and a number of cooling holes 7 are opened on the brake disc body.

[0018] working principle

[0019] By sheathing the disc gasket 8 on the rivet 2, the brake disc is connected to the hub in a floating connection, which effectively solves frictional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com