Wood box and production method thereof

A production method and technology for wooden boxes, which are applied in the direction of manufacturing tools, wood processing appliances, rigid containers, etc., can solve the problems of high mechanical cost, complex processing technology, and only single processing, and achieve fast processing speed, uniform appearance, The effect of machining program simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

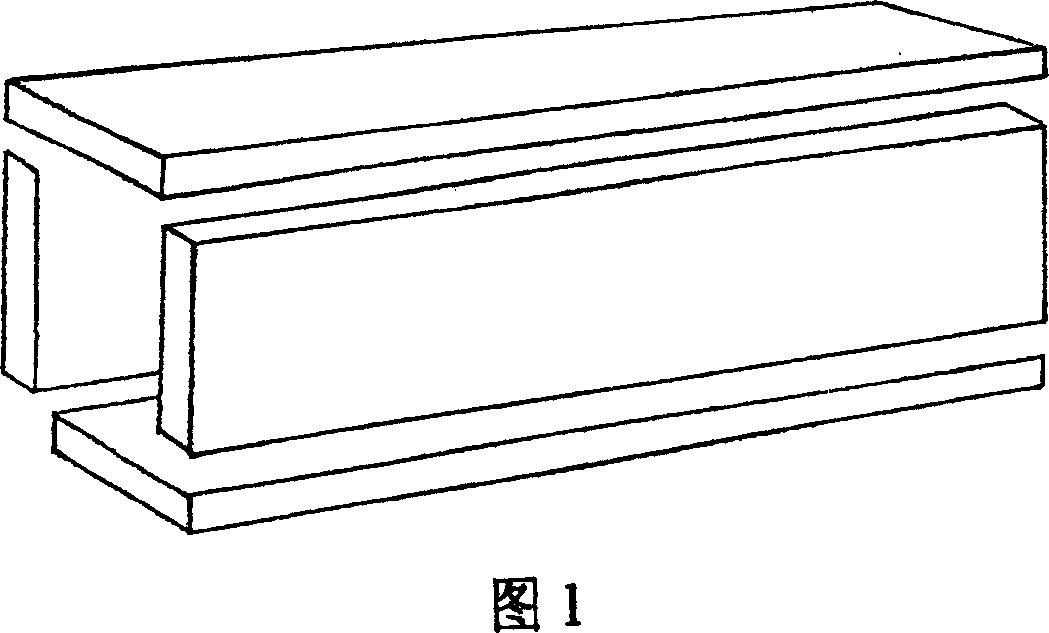

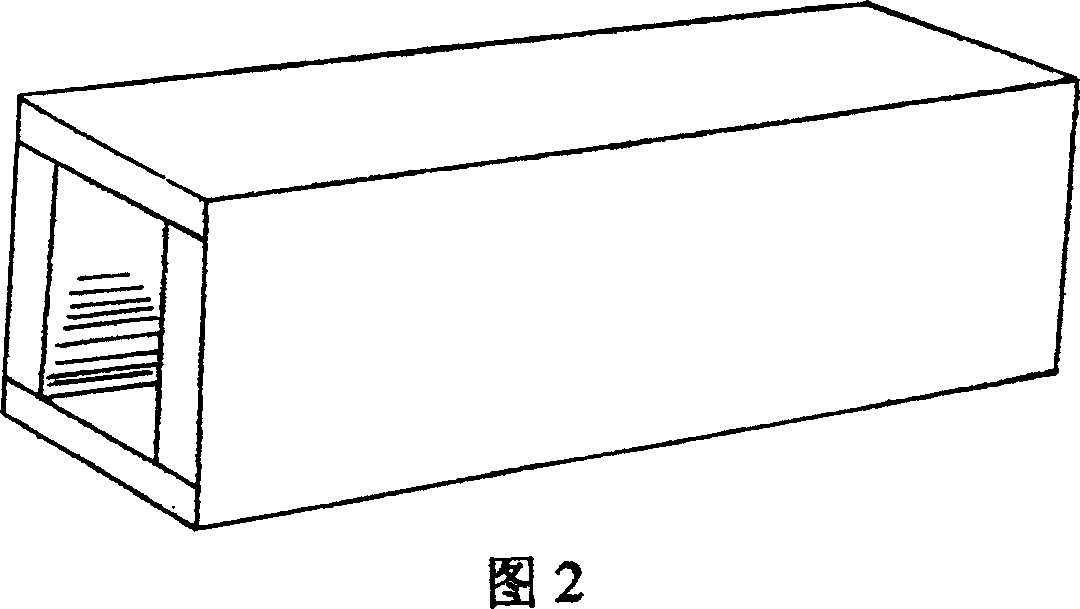

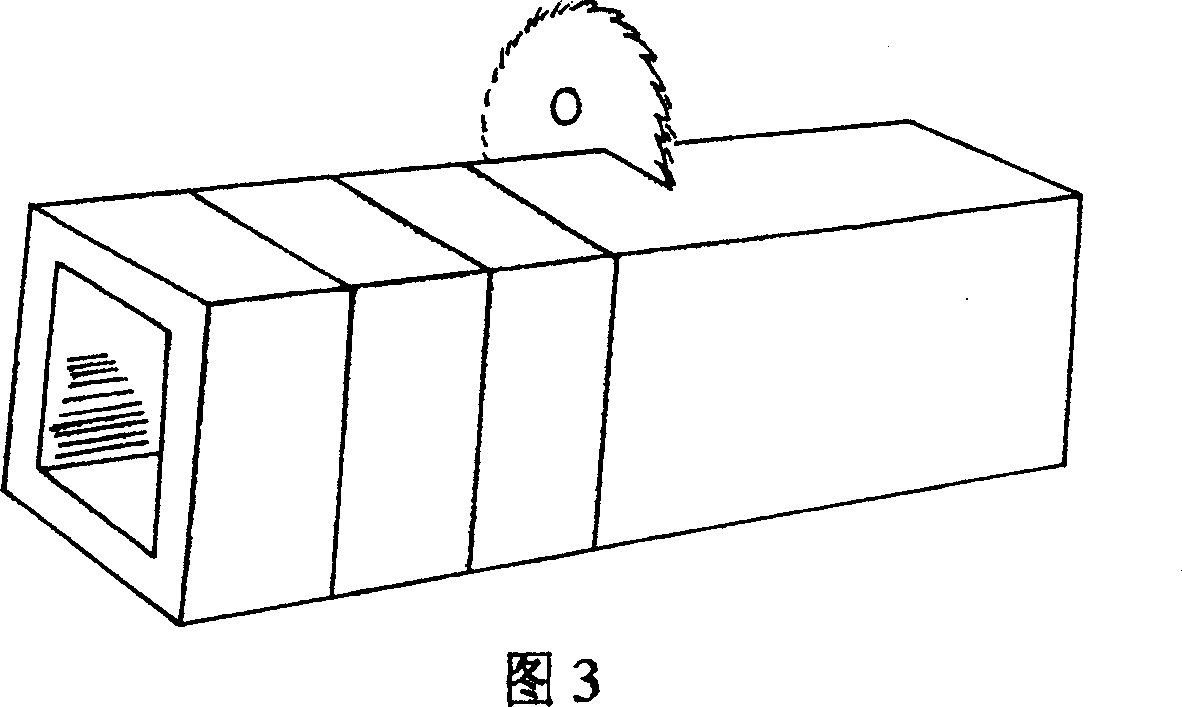

[0028] As shown in the accompanying drawings, the present embodiment adopts four planks to make as an example. First glue four boards together to form a hollow cuboid, and then cut them horizontally to make several independent quadrilaterals. In these hollow quadrilaterals, add solid wood boards of the same shape and size at intervals, and then Carry out bonding successively again, make it become a quadrilateral, at this moment, just can process the outer surface of this quadrilateral with planer or line machine, utilize in general flat machine The gap is enlarged by a certain ratio), and the workpiece is processed with a curved blade. Because the hollow geometry is like the cutting of the whole rectangular wood, it is like the method of cutting thick plates to achieve the processing of the surrounding curved edges, so that it can become various curved surface shapes required. Then cut horizontally along the solid wood board to get several hollow semi-finished products with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com