Industrial equipment glass lens gasket

A technology for glass sight glass gaskets and industrial equipment, applied in the field of sight glass gaskets, can solve problems such as affecting the normal operation of the equipment, not using excessive force, and glass sight glass leakage, etc. The effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

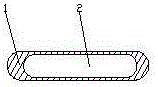

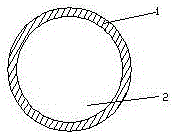

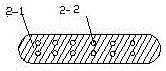

[0013] refer to Figure 1-2 In the past, the gasket viewed hole 2 as the surface opening, and the gasket was easily deformed due to the small area of the sealing surface 1; refer to Figure 3-4 Among them, the gasket sees the hole 2-2 as a point opening, and the area of the sealing surface 2-1 does not change, but the overall strength of the gasket is increased, and it is not easy to deform. Figure 3-4 The viewing holes in the hole are processed by a drilling machine, and the arrangement must be regular. The diameter of the viewing hole is generally φ6-8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com