A method for low-temperature pressing and physical refining of camellia seed oil

A technology of physical refining of camellia seed oil, applied in chemical instruments and methods, food science, edible oil/fat, etc., can solve the problems of camellia oil active substance destruction, food safety hazards, etc., and achieve high retention rate and oil yield rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

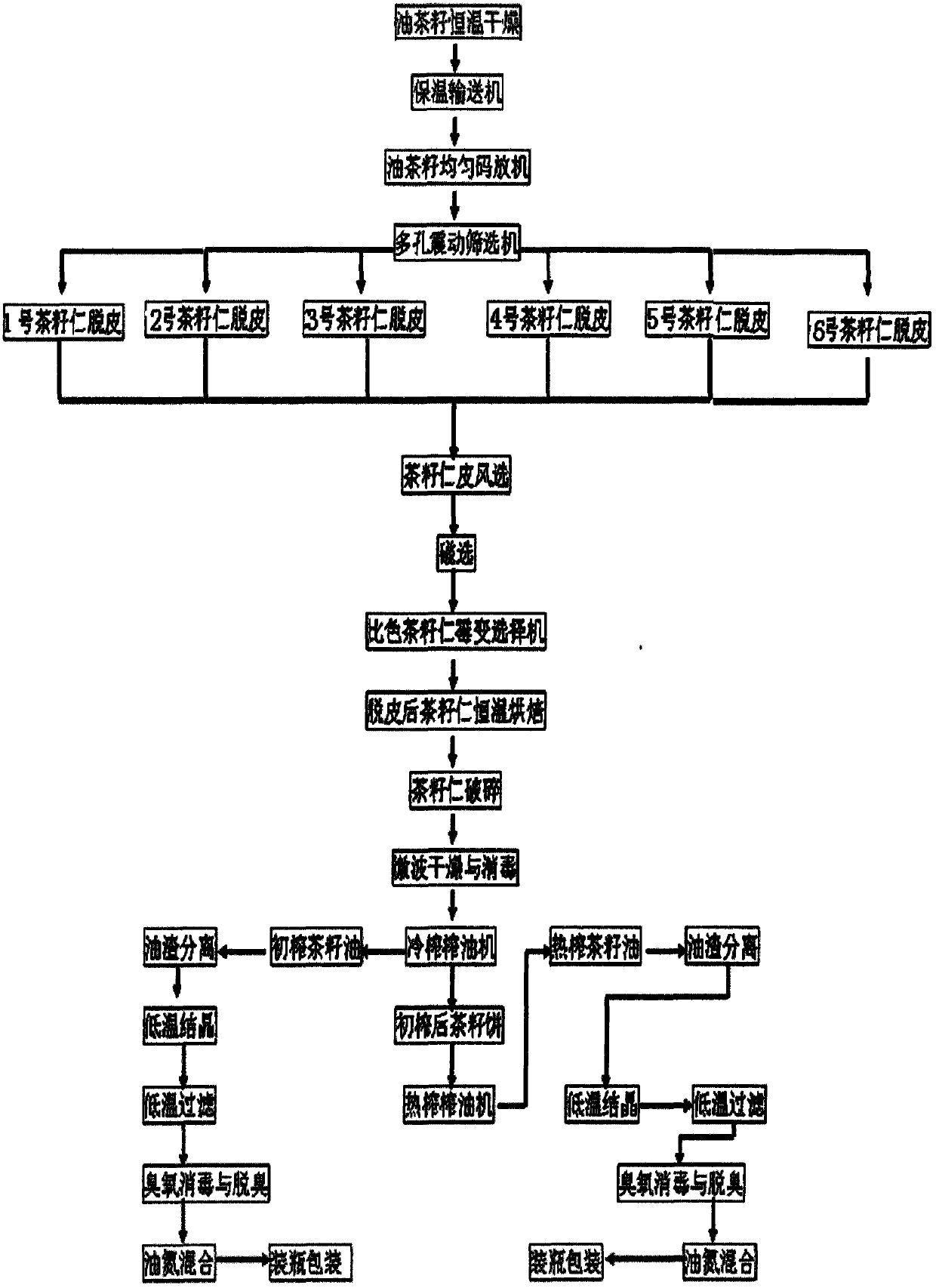

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0053] Concrete recasting agent of the present invention, comprises the steps:

[0054] see figure 1Shown, a kind of method of low-temperature pressing and physical method refining camellia seed oil, comprises the steps:

[0055] 1. Low temperature pressing process

[0056] (1) low temperature storage

[0057] The collected Camellia oleifera fruit is dried and shelled, the camellia seeds are taken out and then dried, and stored in a low temperature environment of 0°C-7°C for 7 days, and the biochemical principle of post-ripening of plant seeds is used to promote the post-ripening of camellia seeds;

[0058] (2) constant temperature drying

[0059] The camellia seeds are evenly heated and dried in the constant temperature hot air drum dryer, the drying temperature is 65°C or 70°C, the moisture content of the camellia seeds is measured by the moisture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com