Crushing press used in kitchen

A technology for presses and kitchens, used in presses, grain processing, manufacturing tools, etc., can solve the problems that materials cannot be pressed and dehydrated, cannot be squeezed and crushed, and filter failures, etc., and achieve high crushing and pressing efficiency. Novel, quick installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

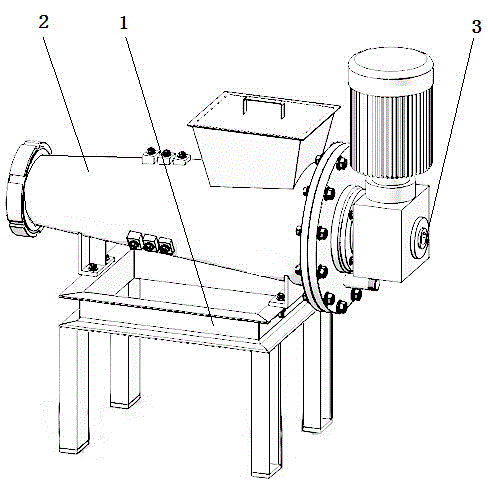

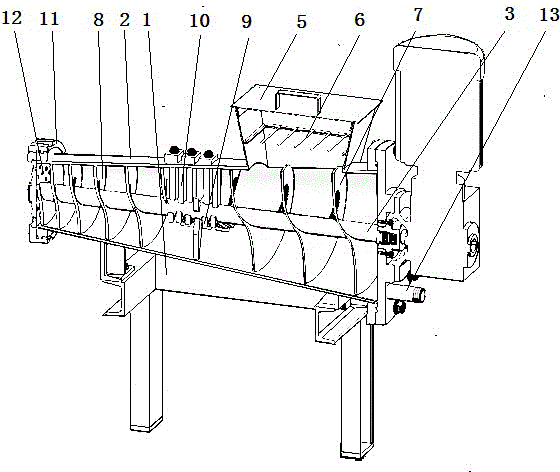

[0017] The present invention is further described below in conjunction with accompanying drawing:

[0018] As shown in the accompanying drawings, a kitchen crushing press includes a frame 1, a cylinder body 2, a transmission shaft 3 and a power source, the cylinder body 2 is fixed on the upper end of the frame 1, and the cylinder body 1 is provided with Transmission shaft 3, the transmission shaft 3 is provided with a helical blade knife, and the transmission shaft 3 is driven by a power source, and it is characterized in that an intercepting grid 6 is horizontally provided on the feeding hopper 5 at the upper end of the cylinder body 2, so as to facilitate Isolate the larger bottles, cans, rags or napkins in the food waste, and let the soft food waste materials enter the cylinder, driven by the transmission shaft, so that the materials are crushed and squeezed out under the action of the spiral blade knife.

[0019] The barrel 2 of the present invention is conical, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com