Household two-level pressing low temperature oil press

An oil press, low temperature technology, applied in the field of household secondary press low temperature oil press, can solve the problems of affecting the sensory and taste of edible oil, endangering human health, shortening the shelf life of edible oil, etc., so as to avoid the loss of quality and nutritional value. , Improve quality and reduce the effect of pre-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

[0038] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited thereto.

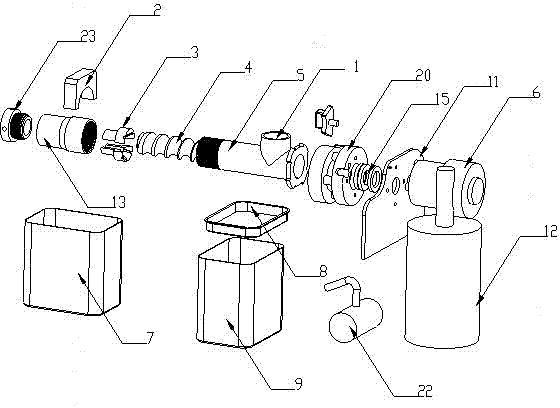

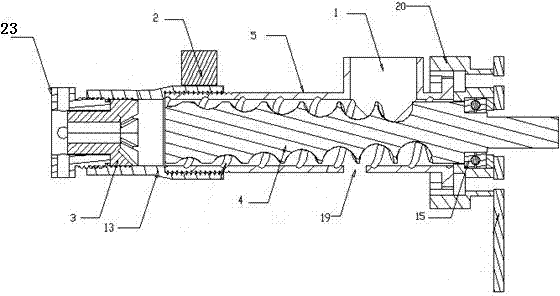

[0039] like figure 1 and figure 2 As shown, this embodiment discloses a household two-stage pressing low-temperature oil press machine, which includes a machine base, a pressing mechanism installed on the machine base, and a driving mechanism that provides power for the pressing mechanism. The pressing mechanism includes a pressing chamber 5, Squeeze head 3, press shaft 4, press head cover 13; press chamber 5 is provided with feed inlet 1, oil outlet 19 and one end is connected to the machine base, press head cover 13 is connected to the other end of press chamber 5, press shaft 4 is provided at one end There is a threaded sleeve in the cavity formed by the press chamber 5 and the press head cover 13, and the other end extends out of the press chamber 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com