Cold-region methane accelerator and preparation method thereof

A technology of accelerator and biogas, which is applied in the field of biogas accelerator and its preparation, can solve difficulties, biogas accelerator can increase gas production and other problems, and achieve the effects of promoting rapid growth, improving the environment of low-temperature fermentation microorganisms, and improving the effect of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

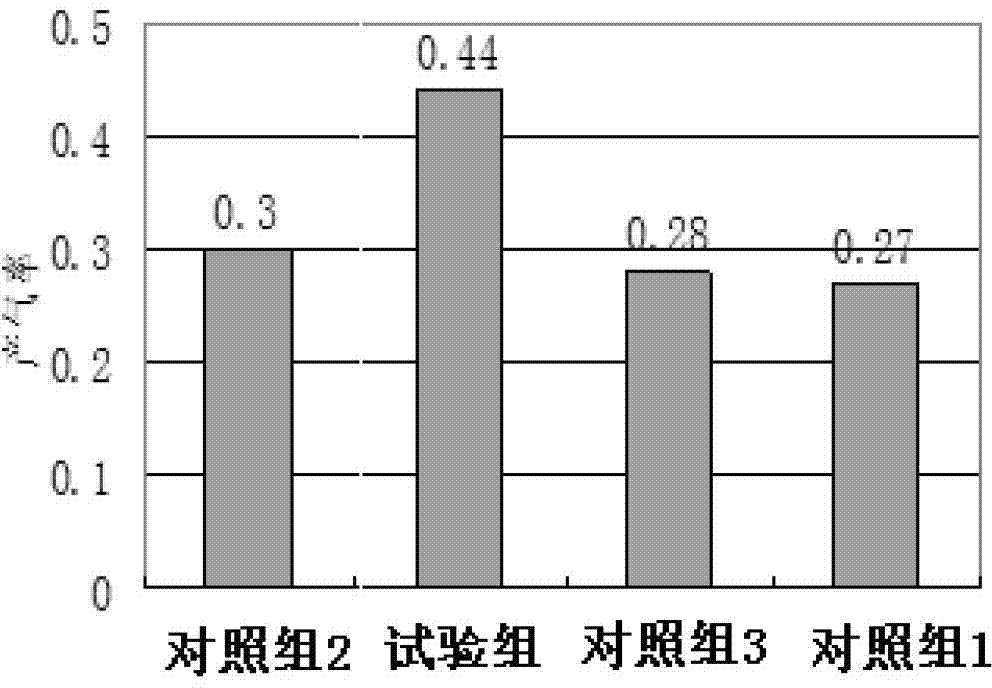

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: a kind of biogas accelerant of cold region of the present embodiment, by mass parts by the ferrous sulfate of 1~2 part, the cobalt chloride of 0.1~1 part, the nickel chloride of 0.5~2 part, 4 ~5 parts of organic matter, 1~3 parts of adsorbent and 80~100 parts of filler; the organic matter is Aspergillus niger and amide nitrogen, and the mass ratio of Aspergillus niger to amide nitrogen is 3:1 ; The adsorbent is activated carbon; the filler is biochar.

[0012] The cold area biogas mentioned in this embodiment refers to the biogas in the alpine area with an annual average temperature below 20°C. There are metal elements beneficial to methanogens in the cold area biogas accelerator of this embodiment, wherein the mass percentage content of iron, cobalt and nickel in the metal elements reaches 0.55%, beneficial organic substances reach 1%; surface adsorbent 2%, Due to the adsorption characteristics, ion dissolution characteristics and biological a...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific surface area of the activated carbon is 500m 2 / g. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the biogas promoter in cold regions is composed of 1.1 to 1.9 parts of ferrous sulfate and 0.2 to 0.9 parts of cobalt chloride in parts by mass , 0.6~1.8 parts of nickel chloride, 4.1~4.9 parts of organic matter, 1.1~2.9 parts of adsorbent and 81~99 parts of filler. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com