Artificial fish reef capable of realizing resource utilization of sea-bottom deposited sludge and preparation method thereof

An artificial fish reef and seabed deposition technology, applied in the fields of application, fish farming, climate sustainability, etc., can solve the problems of high seawater content, resource utilization of difficult seabed sediment silt, etc., and achieve the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

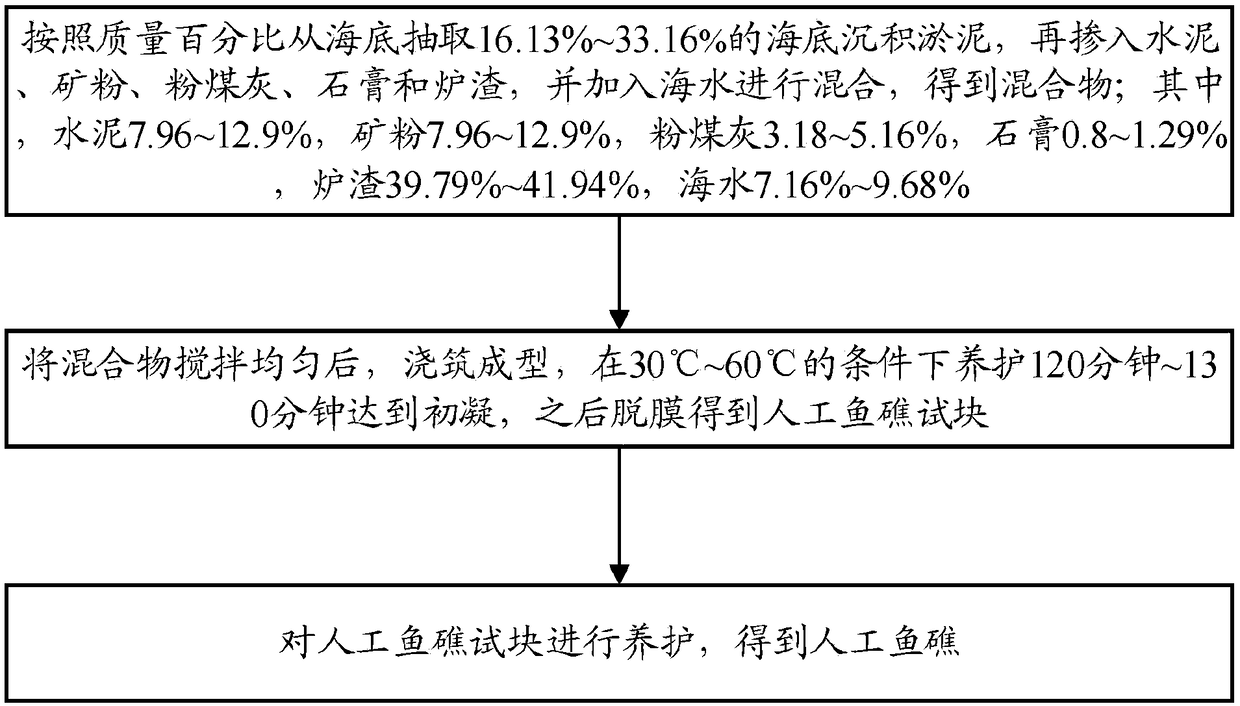

[0022] In addition, the present invention also discloses a method for preparing an artificial reef that can realize resource utilization of seabed sediment silt, including:

[0023] According to the mass percentage, 16.13% to 33.16% of the seabed sediment is extracted from the seabed, and then mixed with cement, mineral powder, fly ash, gypsum and slag, and seawater is added to mix to obtain a mixture; wherein, the water content of the seabed sediment is 40.78%, cement 7.96-12.9%, mineral powder 7.96-12.9%, fly ash 3.18-5.16%, gypsum 0.8-1.29%, slag 39.79%-41.94%, seawater 7.16%-9.68%;

[0024] After the mixture is stirred evenly, it is poured into a shape, maintained at a temperature above 30°C for 120-130 minutes to achieve initial setting, and then the artificial reef test block is obtained by stripping the film;

[0025] The artificial fish reef test block is maintained to obtain the artificial fish reef.

[0026] In order to further optimize the above-mentioned technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com