Crop straw pretreatment method for straw biogas engineering in cold regions

A crop straw and pretreatment technology, which is applied in the direction of waste fuel, fermentation, etc., can solve the problems of long pretreatment time of straw and low enzymatic hydrolysis efficiency, so as to solve the problem of low efficiency and high cost, increase porosity, and reduce the loss of nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A crop straw pretreatment method for straw biogas engineering in cold regions, the steps are as follows:

[0027] Step 1, putting the crop straw into a closed container after crushing, adding water to the closed container to keep the crushed straw at a certain moisture content, compacting the crushed straw, sealing the container, storing it at a certain temperature for a certain period of time to obtain yellow storage straw;

[0028] Step 2: Spray evenly the sodium bisulfite pretreatment solution of a certain mass concentration on the yellow stalks obtained in the step 1, soak at a certain temperature for a certain period of time to complete the pretreatment.

Embodiment 2

[0030] A crop straw pretreatment method for straw biogas engineering in cold regions, the steps are as follows:

[0031] Step 1. Crush crop straws to 0.5 cm and put them into an airtight container. The crop straws include one or a combination of corn straws, wheat straws, rice straws or soybean straws;

[0032] Adding water to the airtight container to keep the moisture content of the crushed straw at 71-75%, sealing the container after compacting the crushed straw, and storing it at a temperature of 5-15°C for 60-90 days to obtain yellow stalks;

[0033] Step 2: Spray evenly the sodium bisulfite pretreatment solution of a certain mass concentration on the yellow stalks obtained in the step 1, soak at a certain temperature for a certain period of time to complete the pretreatment.

Embodiment 3

[0035] A crop straw pretreatment method for straw biogas engineering in cold regions, the steps are as follows:

[0036] Step 1. Crush the crop straws to 0.5 cm and put them into an airtight container. The crop straws include one or a combination of corn straws, wheat straws, rice straws or soybean straws.

[0037] Adding water to the airtight container to keep the moisture content of the crushed straw at 71-75%, sealing the container after compacting the crushed straw, and storing it at a temperature of 5-15°C for 60-90 days to obtain yellow stalks;

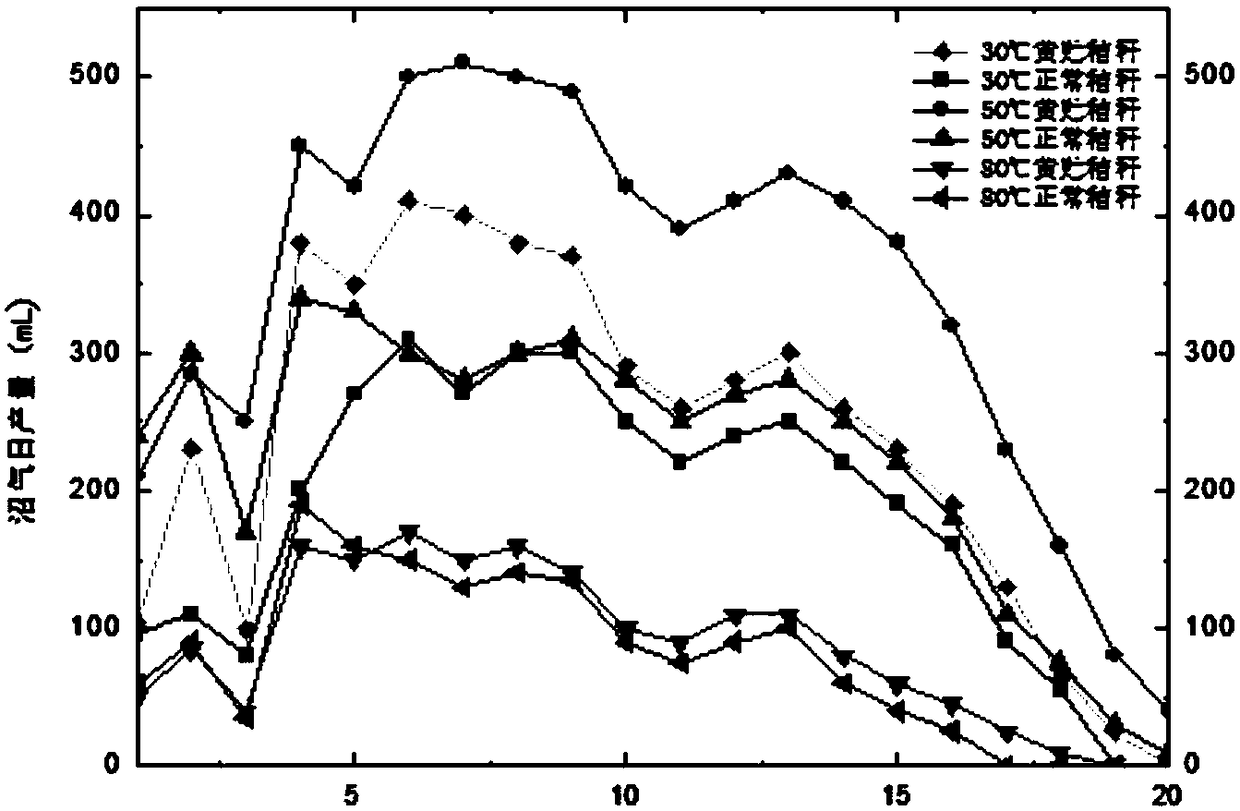

[0038] Step 2. Spray evenly the sodium bisulfite pretreatment solution with a mass concentration of 5-10% on the yellow stalks obtained in step 1 and reach the state of infiltration. , hold the stalks of yellow stalks with your hands, with water droplets between your fingers but not dripping, soak at a temperature of 30-80°C for 65-80 hours to complete the pretreatment.

[0039] In this example, sodium bisulfite is used to chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com