Method for improving anaerobic fermentation gas production performance by repeated freezing/thawing and potassium hydroxide compounded modification of corn stalks

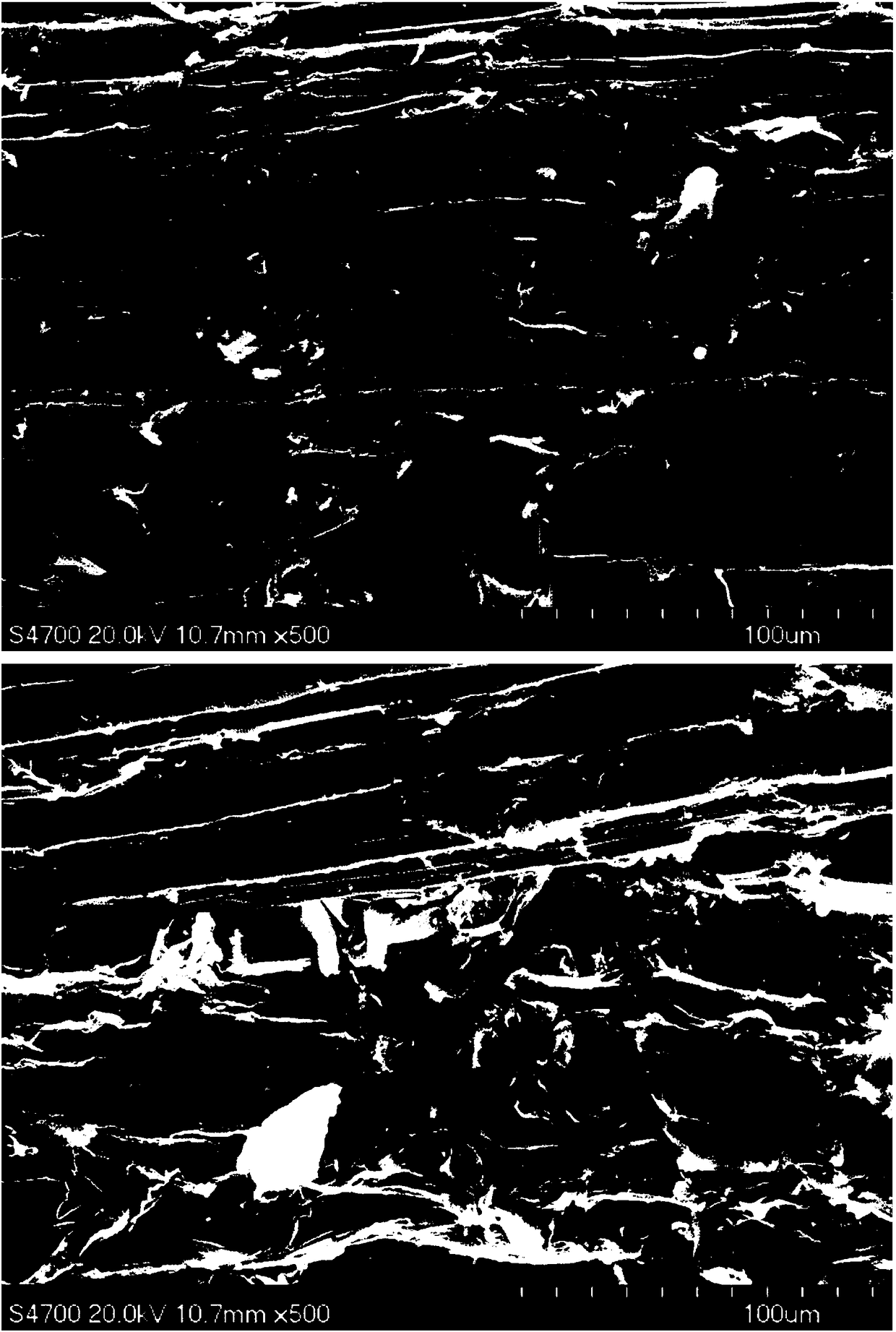

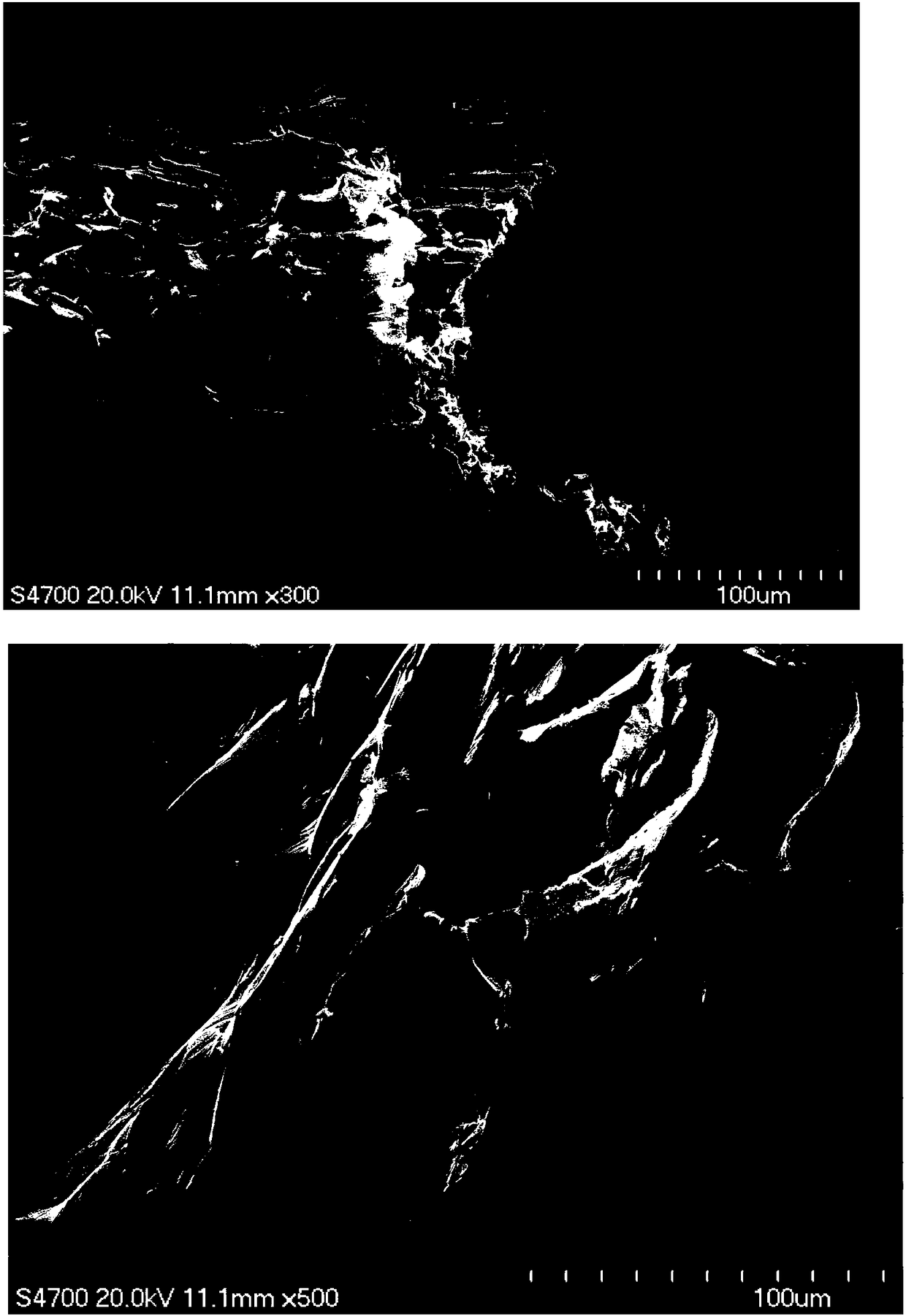

A technology of corn stalks and potassium hydroxide, which is applied in fermentation, biosynthesis, waste fuel, etc., can solve problems that have not been considered, and achieve the effects of saving operating costs, obvious damage to the surface structure, and increasing biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

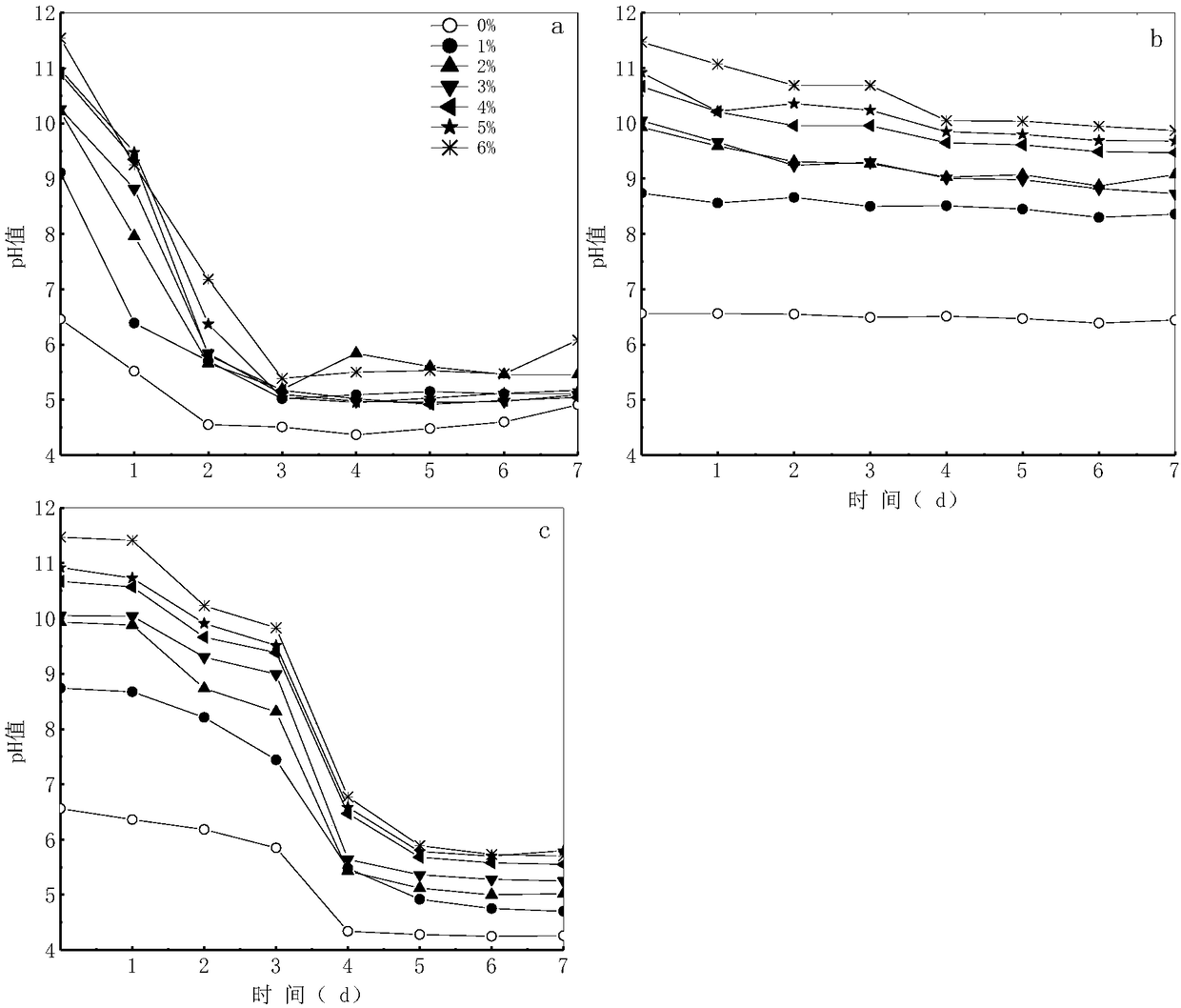

[0026] Taking 9 corn stalk materials with a weight of 38.48g (in terms of dry matter), a single factor pretreatment experiment was designed with solid-liquid ratio (1:5, 1:10 and 1:15 tap water) factors. The above 12 parts of raw materials were sealed at -22°C and 21°C for freeze-thaw pretreatment for 5 days, and the raw materials were taken out and thawed at room temperature for 12 hours after every 12 hours, and kneaded once every 3 hours during the thawing process.

[0027] After the pretreatment, 150 g of anaerobic digester sludge (calculated as MLSS) from a sewage treatment plant in normal operation was added as an inoculum and mixed for anaerobic digestion for 40 days. Meanwhile, the untreated group was set up for anaerobic digestion. Record the daily biogas production by drainage method, measure the percentage of methane every day, calculate the total methane production, and then calculate T 80 . The experimental results are as follows:

[0028] Table 1 Anaerobic dig...

Embodiment 2

[0034] Take 18 parts of 38.48g corn stalk material (in terms of dry matter), add them into a ziplock bag at a fixed solid-to-liquid ratio (1:10) and mix evenly, and design a single factor pretreatment with the cycle number (2-7 times) factor experiment. The above 18 raw materials were sealed and frozen at -22°C and thawed at 21°C for cycle freezing and thawing. Each group of 3 parts, a total of 6 groups, were cycled for 2-7 days, and each group was 12 hours apart. Finally, take the raw materials out and thaw at room temperature for 12 hours, and knead once every 3 hours during the thawing process.

[0035] After the pretreatment, 150 g of anaerobic digester sludge (calculated as MLSS) from a sewage treatment plant in normal operation was added as an inoculum and mixed for anaerobic digestion for 40 days. At the same time, the untreated group was set for anaerobic digestion. The daily biogas production is recorded by the drainage method, the percentage of methane is measured ev...

Embodiment 3

[0040] Weigh 15 parts of corn stalk materials, each raw material has a mass of 38.48g (in terms of dry matter), and add it to the self-sealing Mix well in the bag, and place it at -22°C and 21°C and -41°C and 21°C for freeze-thaw pretreatment for 5 days. treatment group.

[0041] After the pretreatment, 150 g of anaerobic digester sludge (calculated as MLSS) from a sewage treatment plant in normal operation was added as an inoculum and mixed for anaerobic digestion for 40 days. At the same time, the untreated group was set for anaerobic digestion. The daily biogas production was recorded by the drainage method, the percentage of methane was measured every day, the total methane production was calculated, and each pretreatment group was compared. The experimental results are as follows:

[0042] Table 3 Biogas production effect of anaerobic digestion

[0043]

[0044] The above temperature 21 and -22 refer to stable storage at 21°C and -22°C for 4 days respectively, -22+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com